How to Install AEM Electronics V2 Water/Methanol Injection Kit for Force Induction Engines - Multi-Input Controller (79-17 All) on your Ford Mustang

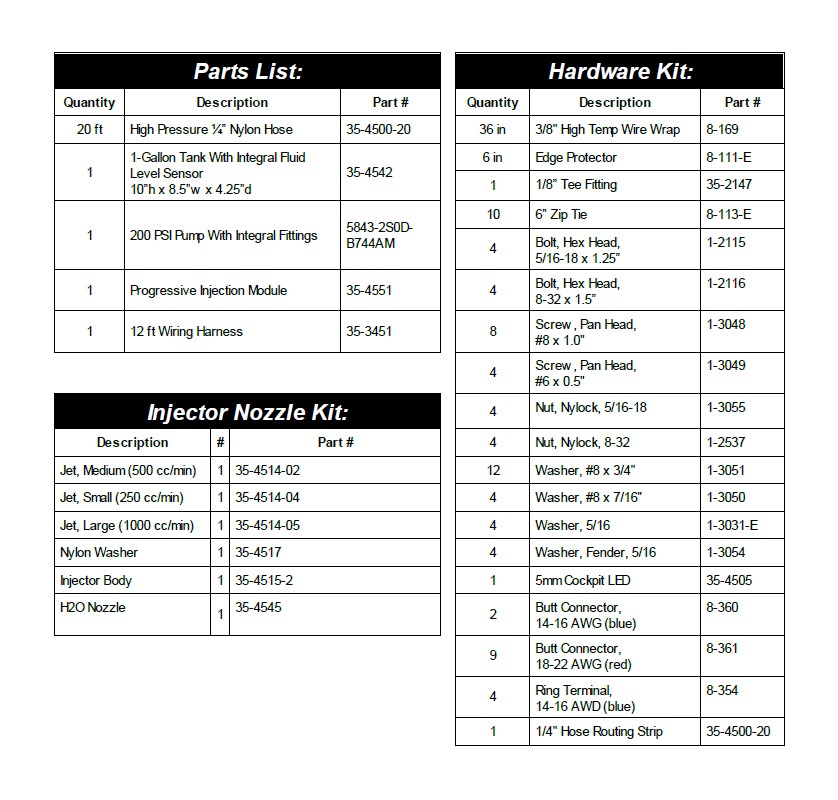

30-3350 Contents

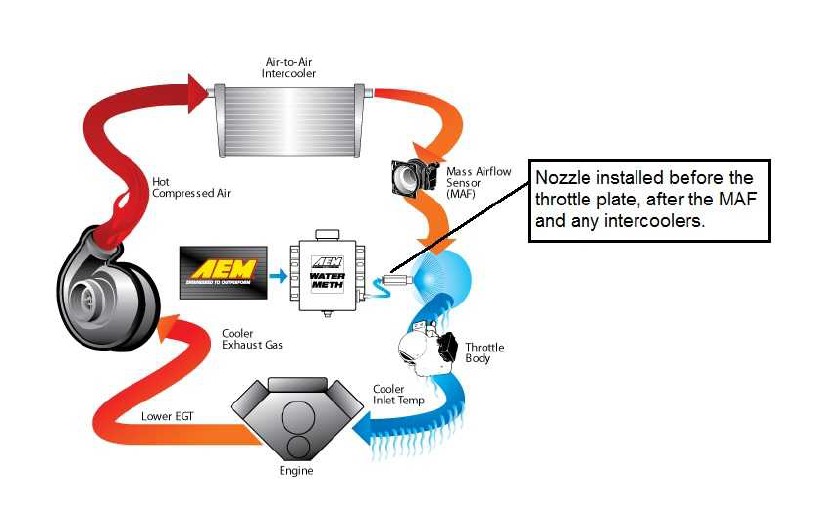

INSTALLATION Diagram

NOTE: THIS KIT INCLUDES NEW STYLE INJECTOR NOZZLES THAT HAVE INTERNAL CHECK VALVES. AN EXTERNAL CHECK IS NO LONGER NEEDED OR INCLUDED IN THIS KIT.

Installation Checklist

The following list of steps is an overview of the installation process. A complete and more detailed list of each step including optional peripherals is defined later in this document.

> Install Tank

- The tank must be mounted such that it is below the injection point. Failure to do

so may lead to fluid leaking into the intake tract due to gravity or siphoning, which

may result in engine damage.

- Fasten with 4 of the 8 supplied #8 sheet metal screws along with the 4 large washers or the 5/16-18 bolts and Nylock nuts.

> Install Pump

- Select suitable location for pump near and below the lowest fluid level of tank.

- Fasten with 4 of the #8 sheet metal screws along with the 4 small washers or the #8-32 bolts and Nylock nuts.

- Cut supplied nylon hose with a sharp razor blade and install from tank to pump.

> Install Controller

- Disconnect ground side of battery during electronic installation.

- Find suitable location for controller inside driver’s compartment.

- Find location in driver’s field of view and install external LED.

- Follow the wire diagram and connect wires from supplied wire harness.

- Connect the blue wire to external input signal.

> Flush Tank

- Connect the remainder of hose to pump. (DO NOT CONNECT NOZZLE.)

- Fill tank with water. (AEM recommends using distilled water.)

- Turn on key power to power on controller.

- Use TEST button on controller to flush the tank into a separate container.

- Drain tank and proceed to next step.

> Connect Nozzle to System

- Select nozzle and connect to nylon hose.

- Fill tank with water.

- Use TEST button on controller to test complete system.

> System Check

- While pushing the TEST button, ensure that no errors are reported and that the system is producing a gradually increasing flow out of the nozzle.

- This may require pressing the TEST button multiple times to purge the system.

- Drain tank and fill with desired water/methanol mixture.

- DO NOT use a hydrocarbon fuel. Water and methanol are the only supported fluids.

> Install Nozzle

- The nozzle must be mounted such that it is above the tank. Failure to do so may

lead to fluid leaking into the intake tract due to gravity or siphoning, which may

result in engine damage.

- Find a suitable location to install nozzle. Nozzle must be mounted before the throttle plate. Nozzle should also be mounted after the MAF sensor if present. Nozzle must also be mounted after any intercoolers.

- Install nozzle, following the instructions for modifying intake to accept the nozzle.

- Cut and install nylon hose from pump to nozzle. Ensure that the hose is not resting, near, or running on any moving or “hot” parts.

> Tune Engine

- Engine tuning is usually required in order to maximize potential power gain.

Pump and Tank Install

Find a suitable location to mount the tank and pump. The tank must be mounted such that it is below the injection point. Failure to do so may lead to fluid leaking into the intake tract due to gravity or siphoning, which may result in engine damage. The tank and pump must be mounted in the same area. Pump may be mounted on exterior of vehicle but should be mounted away from wheel wells or other areas where it will come into direct contact with water or road debris. Pump failures that have clearly been caused by exposure to water/mud/debris will not be covered under warranty. This includes, but is not limited to, the bed of a truck and the inside of the fender wells. Find a location where the pump will remain dry. Use 4 of the 8 supplied #8 sheet metal screws along with the 4 large washers or the 5/16-18 bolts and Nylock nuts to mount the 1-gallon tank.

(Optional 5-Gallon Tank Install)

Before mounting the tank, check the area under the desired mounting location for fuel tanks, fuel lines, or any other obstructions. Mount the tank in an upright level position as shown below. Mark the four mounting points and drill with a 3/8” bit. Use the supplied 5/16-18 bolts, nuts, and large OD flat washers for mounting the tank into your vehicle. IMPORTANT: Use the supplied large OD washer to spread the load on the plastic mounting ears of the tank. DO NOT OVERTIGHTEN! Nuts should just be snug; they are locking nuts and will not loosen. Overtightening will crack the plastic and cause leaks and void the warranty.

Note: All tanks are tested for leaks during assembly. A special sealant adhesive is used to bond the plastic tank to the metal fitting. DO NOT attempt to tighten the fitting any further!

The pump must be located in the same area as the tank and should be mounted at or below the lowest fluid level height.

Take note of the direction of flow, indicated by the arrows on the pump body, when mounting the pump.

Use four #8 sheet metal screws along with the 4 small washers or the #8-32 bolts and nylock nuts to mount the pump. The pump can be mounted in any position horizontally or vertically. Once the tank and pump are mounted, cut the appropriate length of tubing needed to connect the outlet fitting on the tank to the inlet fitting on the pump. Make sure there are no sharp bends in the tubing. Cut the tubing to length with a clean perpendicular slice using a sharp razor blade, making sure the ends are clean and square. Push in the hose at the tank and pump to install. Make sure they are pushed in all the way and check with a light tug on the hose. Secure the hose to the chassis using sections of the supplied hose routing strip or with zip-ties.

Controller Install

The progressive controller is NOT waterproof and should NOT be mounted in the engine bay! Find a convenient location for the controller inside the driver’s compartment. The adjustment knobs should remain in an accessible location but still remain protected from possible water incursion. If you need to extend the wires to mount the controller use at least 16 AWG wire for the pump and controller ground circuits and 18 AWG for the remainder. The controller contains an externally accessible fuse; no additional fuses are required. Use the supplied zip-ties to mount the controller.

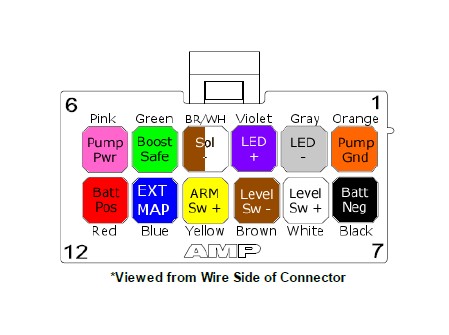

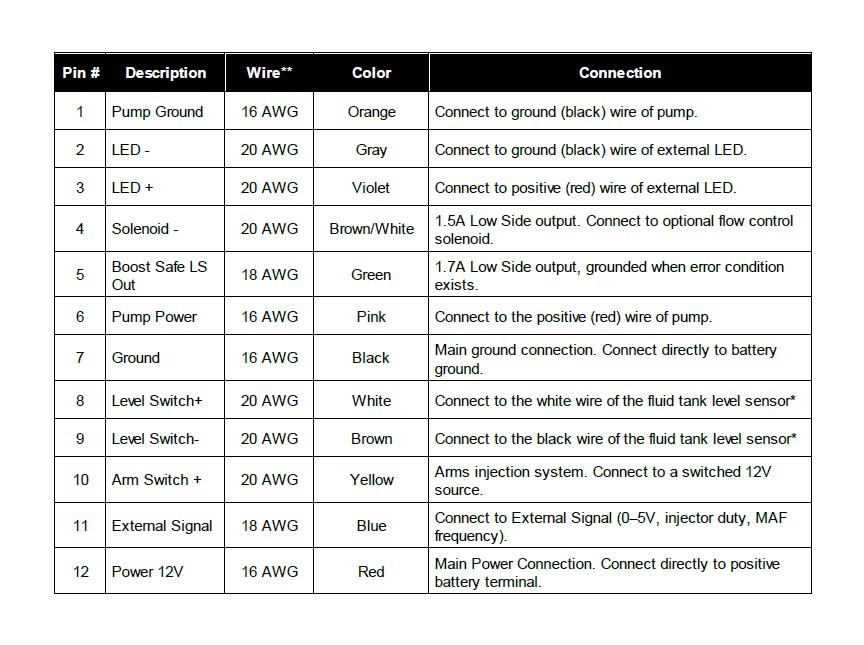

Progressive Controller Installation

*Note: If fluid tank is equipped with previous generation level sensor, identified by having two black wires, then pins 8 (white) and 9 (brown) may be connected to either of the two black sensor wires. The polarity is unimportant. **Note: If you need to extend the wires to mount the controller use at least 16 AWG wire for the pump and controller ground circuits and 18 AWG for the remainder.

External LED Install

Find a suitable location in the driver’s line of sight to mount the external LED. Mount the LED and run the wires to the controller. The LED indicates the operation of the controller. If the pump is off and there are no errors, the LED will be off. If there are no errors and the pump is on, the LED intensity will vary with the pump speed. If there are any errors, they will be indicated by flashing the LED.

External MAP, Injector Duty, MAF Overview

The connection of the External MAP/MAF pin will depend on the desired mode of operation. Please follow the table in determining where to connect this wire.

*Please consult the factory service manual to find the appropriate wire to tap for the above connections. It is acceptable to make this tap close to the sensor/injector or nearer to the ECU itself, whichever is more convenient.

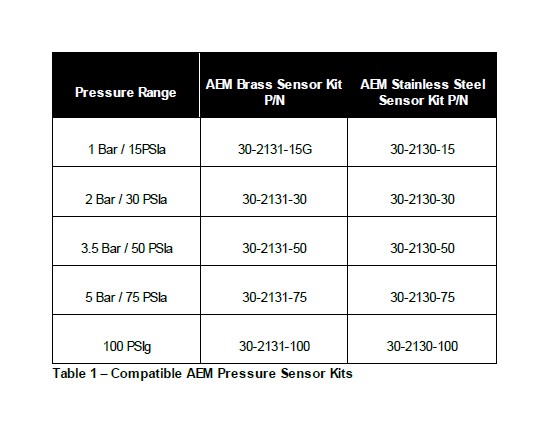

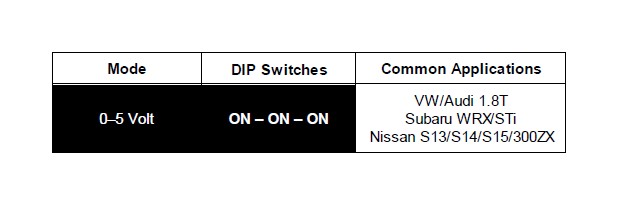

External MAP 0–5V Installation

Operation:

The 0–5 Volt external MAP mode is designed for vehicles running high boost, beyond that of the Internal and HD models, or for users who already have a sensor or output of their MAP with a range of 0–5 Volts. See Table 1 for compatible AEM MAP sensors.

Dip Switch Settings:

ON – ON – ON

Setup, Connection:

To set up your system for external MAP you must first find the correct source to connect to. In order to locate the correct signal the use of a voltmeter is required. Once you have located your MAP sensor, check the wires to find the “signal” wire. The signal wire should remain at or near 0 Volts when the car is turned off or is not running. Once the vehicle is started, it should continue to remain at or near 0, though it may begin oscillate up and down slightly. To determine if you do in fact have the correct wire, rev the engine while monitoring the voltage. You should observe the signal rising and falling with engine speed. Please note that you may need to rev the engine high enough to put it into boost. Once you have found the correct signal wire, you may tap onto it (if it is used by other devices), or connect it directly to the Water/Methanol Controller (Pin #11 – Blue).

Testing:

To test your setup it is recommended you finish the installation, but before installing the nozzle run the engine and ensure the system is operating as expected. That is, when the engine is running and the MAP sensor is outputting in a range set by the controller you will get flow. You want to ensure you are not getting flow when the engine is turned off or it is not expected. This could be due to improper wiring or having the incorrect mode selected.

Injector Duty Installation

Operation:

The Injector Duty mode is designed for vehicles where water/methanol injection rate is desired to be highly coupled to the injector duty, meaning the more fuel the more water/methanol. This mode can be used when MAF is not available, or in NA vehicles. Injector duty is NOT intended to work with diesel or other multi-pulse injection systems.

Dip Switch Settings:

OFF – OFF – ON

Setup, Connection:

To set up your system for injector duty you must first find the correct signal wire to connect to. You must locate and tap on to one of the two wires going to the fuel injector. One of the wires will be switched 12V (typically red) and the other will be the desired signal wire from the ECU. Using a voltmeter you can determine if you have the correct wire by watching the voltage as the engine is running. As duty cycle increases and more fuel injected, the measured DC voltage will appear lower as viewed on a voltmeter. If you have an oscilloscope or a way to measure duty cycle, this is even better. Once you are sure you have the correct signal you can tap onto the signal and connect that to pin #11 (blue wire) on the controller.

Testing:

To test your setup it is recommended you finish the installation, but before installing the nozzle run the engine and ensure the system is operating as expected. That is, you want to ensure you are not getting flow when the engine is turned off or it is not expected. This could be due to improper wiring or having the incorrect mode selected.

0–5V MAF Installation

Operation:

The 0–5 Volt MAF mode is designed for vehicles where MAF is used and the output of their MAF sensor is 0–5V

and not a frequency.

Dip Switch Settings:

Setup, Connection:

To set up your system for MAF you must first find the correct source to connect to. In order to locate the correct signal the use of a voltmeter is required. Once you have located your MAF sensor, check the wires to find the “signal” wire. The signal wire should remain at or near 0 Volts when the car is turned off or is not running. Once the vehicle is started, it should continue to remain at or near 0, though it may begin oscillate up and down slightly. To determine if you do in fact have the correct wire, rev the engine while monitoring the voltage. If the signal rises and falls with the engine speed, then you have likely identified the correct wire. If you are experiencing difficulty locating the signal wire, refer to the vehicle’s service manual to locate the MAF signal wire, and then try to verify again with a voltmeter. Once you have found the correct signal wire, you may tap onto and connect it to pin #11 (blue) of the Water/Methanol Controller.

Testing:

To test your setup it is recommended you finish the installation, but before installing the nozzle run the engine and ensure the system is operating as expected. That is, when the engine is running and the MAF sensor is outputting in a range set by the controller you will get flow. You want to ensure you are not getting flow when the engine is turned off or when it is not expected. This could be due to improper wiring or having the incorrect mode selected.

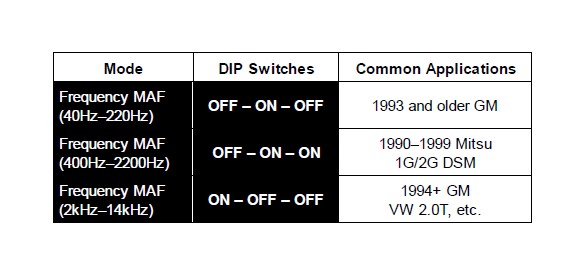

Frequency MAF Installation

Operation:

The Frequency MAF mode is designed for vehicles where MAF is used and the output of their MAF sensor is digital and a frequency.

Dip Switch Settings:

Setup, Connection:

To set up your system for MAF you must first find the correct source to connect to. In order to locate the correct signal, the use of a voltmeter is required. Once you have located your MAF sensor, you can begin to check the wires for the “signal” wire. The signal wire should remain at or near 0 Volts when the car is turned off or is not running. Once the vehicle is started, it should remain at or near 2.5 Volts. This is because the signal has a duty cycle of 50% and a voltage range of 0–5V, so the average voltage will be near the middle of this range. To determine if you do in fact have the correct wire, rev the engine while monitoring the voltage. It should remain the same regardless of the engine speed. If you are experiencing difficulty locating the signal wire, refer to the vehicle's service manual to locate the MAF signal wire, and then try to verify again with a voltmeter. Once you have found the correct signal wire, you may tap onto it and connect it to pin #11 (blue) of the Water/Methanol Controller.

Testing:

To test your setup it is recommended you finish the installation, but before installing the nozzle run the engine and ensure the system is operating as expected. That is, when the engine is running and the MAF sensor is outputting in a range set by the controller you will get flow. You want to ensure you are not getting flow when the engine is turned off or when it is not expected. This could be due to improper wiring or having the incorrect mode selected.

Pump/Tank Flush

After all wires are hooked up, add water to the tank and, with the hose pointed into a container, press and hold the TEST push button on the controller module. The TEST button can be used to test the system. The pump speed will gradually increase from zero to full speed within 3 seconds and then remain full for another 3 seconds before stopping. Repeat the TEST button procedure until you are sure the system is free of any debris that may have been in the lines or tank. Drain the water out of the tank and refer to the next section on installing the nozzle.

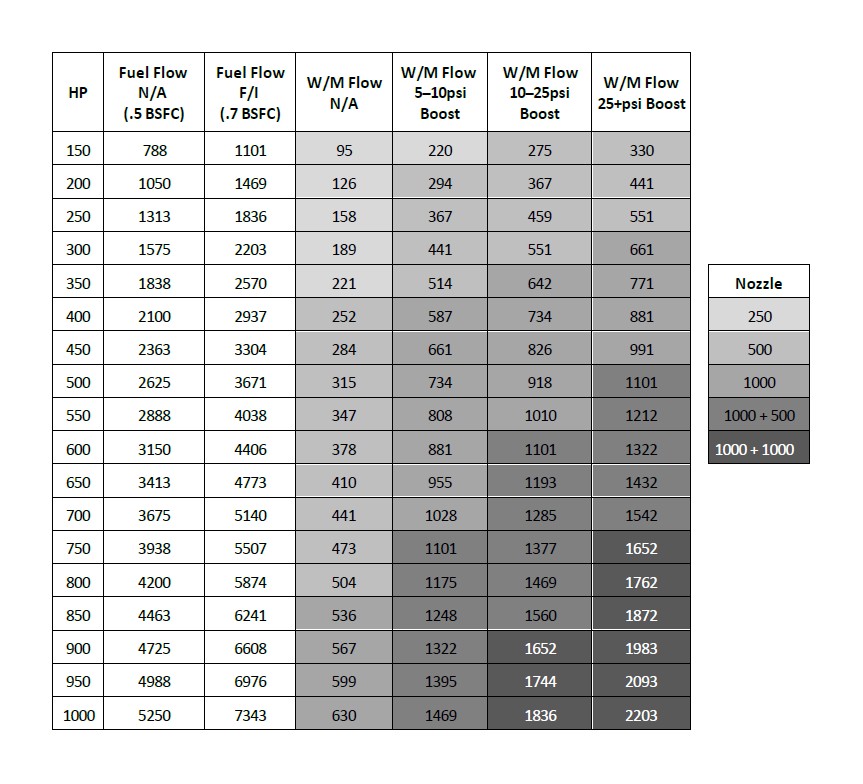

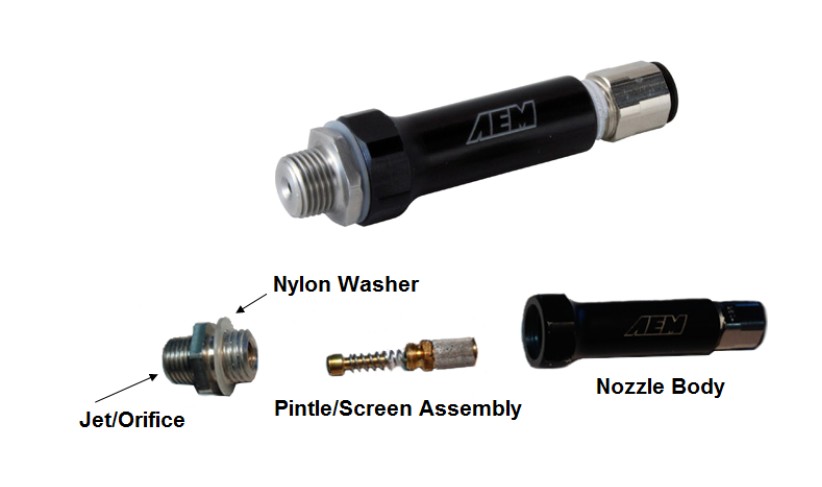

Nozzle Selection and Assembly

This injection kit includes three differently sized injection jets that cover a very large range of horsepower levels. Use the following chart to select the appropriate jet for your power level. The kit comes with one medium nozzle already preassembled.

The nozzles are serviceable and can be disassembled for cleaning. If you find excessive debris in the screen, check your tank for contamination. When installing the screen it is only necessary to be slightly tighter than finger tight. Do not over-tighten. The nylon washers are reusable but a spare is included.

Nozzle Mounting

Select the location where the nozzle will be installed. Nozzle must be mounted such that it is higher than the tank. Failure to do so may lead to fluid leaking into the intake tract due to gravity or siphoning, which may result in engine damage. Nozzle must be mounted before the throttle plate. Nozzle should also be mounted after the MAF sensor, if present. Nozzle must also be mounted after any intercoolers. In most instances, mounting the nozzle 6–8” ahead of the throttle body provides an excellent combination of air charge cooling and combustion control.

In most instances, the air charge piping can be drilled and tapped for 1/8” NPT to directly mount the nozzle. If using thin walled tubing it’s suggested that a bung be welded to the piping. Mounting hole should be tapped deep enough to allow the end of the nozzle to be nearly flush with the interior of the intake once the nozzle is fully installed.

Pump/System Check

The TEST push button on the controller module can be used to test the system. Press and hold the button to activate the pump. The pump speed will gradually increase from zero to full speed within 3 seconds and then remain full for another 3 seconds before stopping. When the button is released the controller will return to normal operation.

Add water to the tank and, with the nozzle pointed into a container, press and hold the TEST button. The flow will start gradually and increase to a steady amount. If this happens, then your system is connected properly. Check and repair any leaks. Drain the water out of the tank and install the nozzle.

Fluid Compatibility

Under NO circumstances should any hydrocarbon based fuel ever be used with this system. Water and methanol are the ONLY fluids to be used.

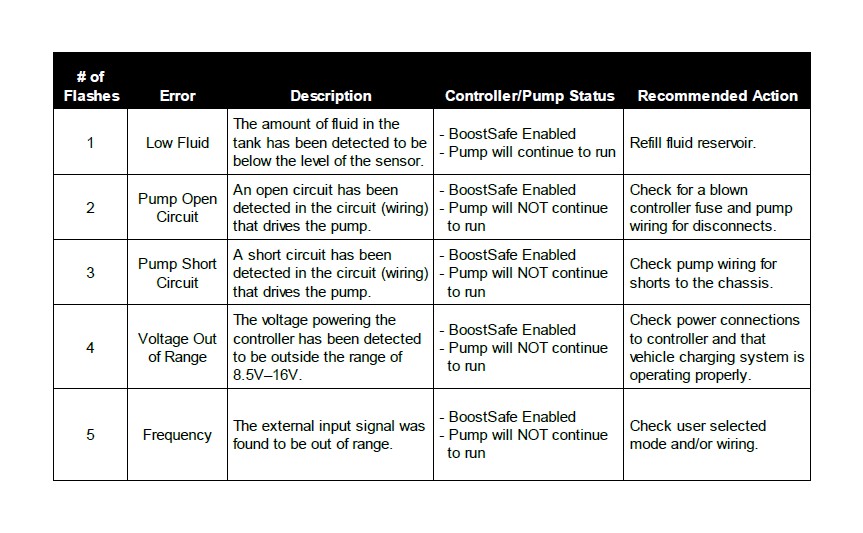

SYSTEM ERRORS

The controller will continuously check for errors; when an error is detected it will be reported to the user by a flashing sequence of the external LED, as well as a corresponding red flashing sequence of the status LED. Damage to vehicle or engine may occur if these faults are not resolved immediately. The water-injection system may not operate properly or at all while an error condition exists. Please refer to the table below for further information.

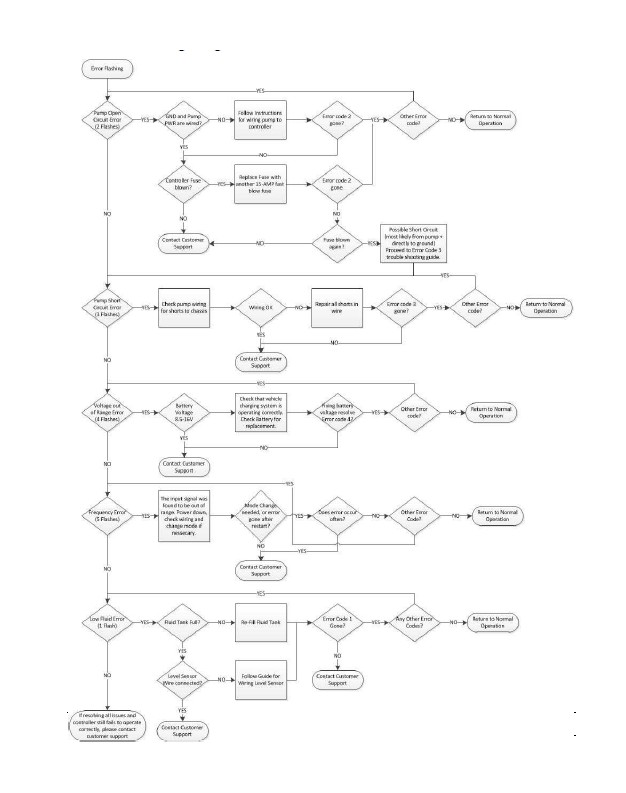

Troubleshooting Diagram

CONTROLLER

Settings

The AEM Water/Methanol Injection Controller is a progressive type controller. This means that fluid will be injected in proportion to the amount of boost that is detected by the external MAP input. In other words, higher signal input equals more fluid. It is therefore imperative that the external signal connection be made properly and securely or vehicle/engine damage could occur. In addition, the controller will automatically compensate for any fluctuations in battery voltage variations to ensure consistent flow under all conditions.

The two knobs on the face of the controller dictate at what signal input minimum fluid injection starts and at what signal input maximum/full fluid injection occurs. Fluid injection will ‘progressively’ increase between these two points as set by the adjustment knobs.

The “Start” dial has a range from 0% (full counterclockwise rotation) to 100% (full clockwise rotation). The “Full” dial has a range of 0% (full counterclockwise rotation) to 100% (full clockwise rotation). It is suggested to adjust the “Start” value by setting the dial to approximately 25% of the vehicle's maximum signal input. Adjust the full-in value to your maximum possible percent for signal input. These are only suggestions; improper use or setting could result in engine or vehicle damage – please consult your tuner.

Mode Selection

The mode can only be selected or changed while the unit is turned off. To change the mode remove the back cover exposing the three DIP switch selectors. Follow the guide on the controller to select the appropriate mode for your application.

Status LED

The controller has an on-board Status LED. This will mimic the operation of the external LED. Upon startup the current mode is flashed in green on the status LED. It will flash error codes in red as well as illuminate with varying intensity as a function of flow in green.

Fuse

The controller has an externally accessible fuse. The controller itself will turn on and function, but the pump will not run without the fuse. If the controller is reporting an open circuit it may be that the fuse has blown or is not installed correctly. Use a 15 amp fast blow fuse for replacement purposes.

TEST Button

The TEST button feature is available to test the system's functionality. This feature should be used ONLY with the nozzle disconnected from the engine. This is to prevent unintentional pumping of fluid into the engine. To operate the TEST button, press and hold. The pump speed will gradually increase from zero to full speed within 3 seconds and then remain at full speed for another 3 seconds before stopping. Flow should begin gradually and then hold at full pressure for a total test time of 6 seconds.

Short Circuit Self-Diagnostics

There are two modes of pump-driver short circuit protection available. One can detect a short at any time but produces a slight buzzing in the pump. This should not be noticeable under most conditions but can be turned off if it is objectionable. If turned off, a short circuit can only be detected when the pump is running.

To enable or disable this diagnostic (and the buzzing): Press and hold the TEST button while applying power to the controller. The change is acknowledged by a single long flash of the status LED output and the external LED. Once the button is released the controller will continue to function normally. You can also tell what mode has been selected by listening for the buzzing sound in the pump. Repeating this operation will toggle between the two modes.

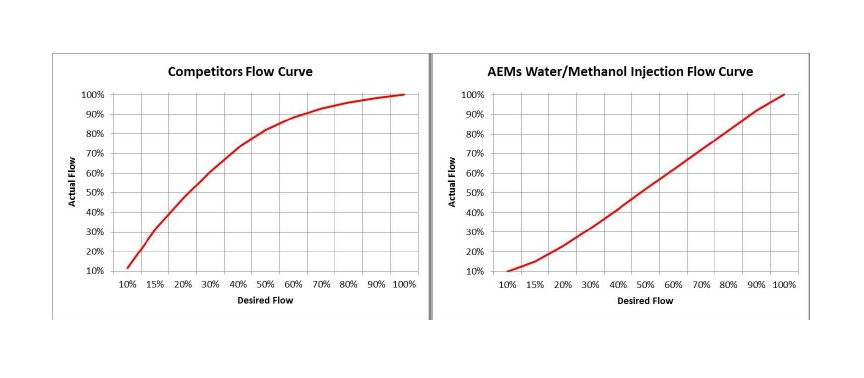

A MORE LINEAR FLOW OUTPUT

AEM’s Water/Methanol Injection system delivers a linear flow rate as pump speed increases. This is unlike competitors’ systems that simply have a linear pump speed drive between start and full setting which results in a non-linear delivery of water/methanol. AEM’s system linearizes the flow, giving you better flow control and a more progressive delivery of water/methanol.

BOOST-SAFE OUTPUT (optional)

The progressive controller includes a Boost-Safe output (grounded when active) that activates whenever the system is armed and runs out of fluid or an error code is flashing. The green wire on the controller is the 1.7 amp switched ground. This wire can be hooked up to a solenoid that will vent waste gate pressure when activated. Apply 12V to the other side of the solenoid (AEM P/N 30-2400 or equivalent). This output can also be used to trigger a timing retard function in a standalone ECU or a CDI whenever the system runs out of fluid, thus protecting your engine. It is highly recommended that this feature be utilized.

SOLENOID DRIVER (optional)

The progressive controller includes a Solenoid output (Brown with white strip wire, grounded when active, 1.5A max) that activates whenever the system is pumping. The wire should be connected to the ground side of a solenoid, with the other end of the solenoid connected to switched ignition power. The solenoid should be installed after the pump and before the nozzle. For best results install the solenoid close to the nozzle.

NON-PROGRESSIVE OPERATION (optional)

The progressive controller is capable of operating in a non-progressive manner, acting as a full-on or full-off type system. To set this up the “Full PSI” knob must be set to a lower value then the “Start PSI” knob. This means as soon as the boost exceeds the “Start PSI” threshold the pump will begin pumping at its maximum flow since it has passed both the start and the full requirements.

ENGINE TUNING

Water/methanol injection is generally not considered a bolt-on power adder for forced induction gasoline applications. Engine tuning is usually required in order to maximize potential power gain. Water/methanol injection allows for a more aggressive tune to be used while still using pump gas as your base fuel.

Using a 50/50 mix of water/methanol is recommended for the best combination of air charge cooling and detonation control. With conservative boost and timing, establish a base AFR that is one point higher than your final target AFR. For example, if your final target AFR with water/methanol injection is 11.0:1, set your base AFR to 12.0:1. Once the base AFR has been set, start injecting water/methanol and adjust the injection flow rate to achieve your final target AFR. For example, if before injection your base AFR is 12.0:1 and then during injection your AFR drops to 10.5:1, reduce the water/methanol flow rate until your final target AFR is reached. It is generally recommended that the flow rate of the injection system be changed in order to reach your target AFR and NOT your primary fueling. Injection flow rate adjustments can be made by changing your nozzle selection or by adjusting the “Start PSI” and “Full PSI” settings.

Once the injection flow rate is set to deliver your desired final AFR, boost and ignition timing can be increased to take advantage of the additional air charge cooling and detonation control. When injecting the correct amount, a 50/50 mix of water/methanol has been shown to provide an effective octane of over 110 when using a base fuel of 91–93 octane pump gas. A properly tuned water/methanol injection system will usually support a typical “race gas” engine tune.

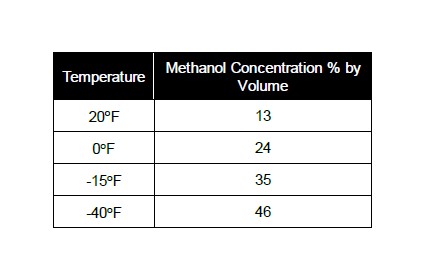

COLD WEATHER OPERATION

A water/methanol mix will also lower the freezing point of the fluid. Below is a chart with freezing points for different percentages of water/methanol mixtures.

MAINTENANCE

The injector nozzle should be cleaned periodically. Disassemble the nozzle and clean it with a suitable cleaner until all debris is removed. If excessive contamination is found, check the rest of the system for the source.