How to Install AEM Electronics X-Series Voltmeter Gauge - Electrical (79-17 All) on your Ford Mustang

Shop Parts in this Guide

STOP! - READ THIS BEFORE INSTALL OR USE!

WARNING:

THIS INSTALLATION REQUIRES WELDING AND INTEGRATION INTO A VEHICLE'S ELECTRICAL SYSTEM. DAMAGETO SENSITIVEELECTRONICS, FIRE, OR EXPLOSIONMAY OCCUR IF PROPER PRECAUTION IS NOT TAKEN. IF THEREIS ANY DOUBT, DO NOT ATTEMPT THEINSTALLATION AND CONSULT A PROFESSIONAL.

NOTE: IT IS THERESPONSIBILITY OF THEENGINETUNER TO ULTIMATELY CONFIRMTHECALIBRATION USEFOR ANY PARTICULAR ENGINEIS SAFEFOR ITS INTENDED USE. AEMHOLDS NO RESPONSIBILITY FOR ANY ENGINE DAMAGETHAT RESULTS FROMTHEMISUSEOF THIS PRODUCT.

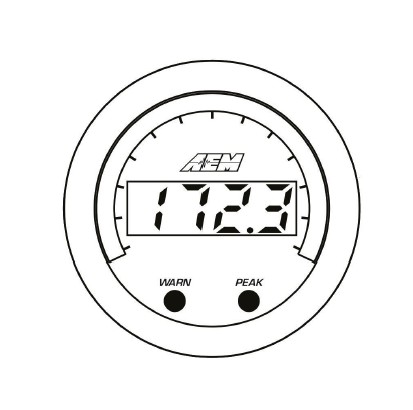

The 52mm (2-1/16”) AEM X-Series Gauge features a four digit central readout and sweeping 24-color-coded LED display, providing immediate reference to the sensor reading in real-time. A 0-5V analog and an AEMnet (CAN bus) output is included and can be used with data loggers or aftermarket ECUs including the AEM Infinity Engine Management System (EMS).

Features

· 2-1/16" / 52mm outer diameter mounting

· Flashing warn / alarm feature

· Peak recall

· Black bezel / "Volt" faceplate supplied; Silver / white available as optional purchase

· Locking connectors

· Supports vehicle / system voltages up to 16V

· Auto-dimming display

Wiring Installation Diagram

Operation

The inner numeric LEDs and outer ring LEDs display the currently measured sensor reading; the inner numeric LEDs will flash when the sensor reading exceeds the (configurable) warn/alarm threshold value. WARN and PEAK buttons are located on the face of the gauge and are used to perform the following functions.

Display or adjust warn/alarm threshold

. Press the WARN button; the warn/alarm threshold will be displayed and the outer LEDs will flash

. Use either the WARN or PEAK buttons to decrement or increment the threshold value

. Depress and hold both the WARN and PEAK buttons until LESS or GrTr appears

. Press the WARN button to toggle between LESS and GrTr modes

Warn/alarm activated when sensor reading is less than threshold value

Warn/alarm activated when sensor reading is greater than threshold value

. The gauge will return to normal display mode a few seconds after the last button press

Display or clear stored peak value

. Press the PEAK button; the peak (highest) sensor reading will be displayed and the outer LEDs will flash

. The peak value will be retained across power cycles

. While the peak value is being displayed, depress and hold the PEAK button for three seconds until "CLr" appears to clear the peak value

Will be displayed to confirm the peak value has been reset

. The gauge will return to normal display mode shortly after the last button press

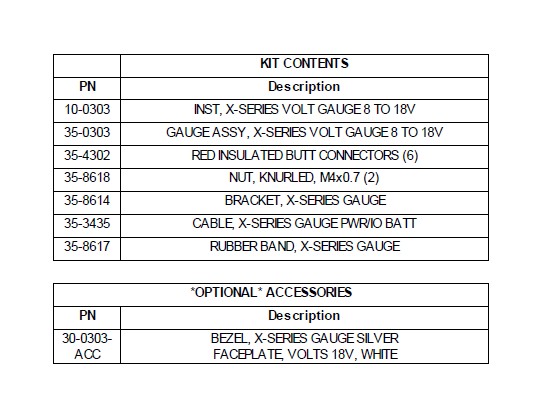

Faceplate / Bezel Installation

The gauge kit is supplied assembled with a black faceplate and black bezel. An accessory kit is available (for purchase through AEM dealers) which includes an optional silver bezel and white faceplate. Please reference the Optional Accessories section earlier in the document for the appropriate part numbers. Contact your dealer or visit www.aemelectronics.com for more information.

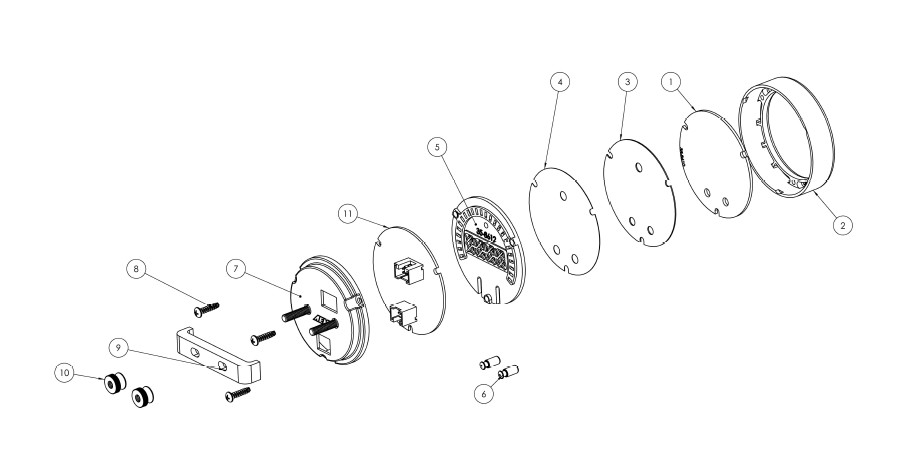

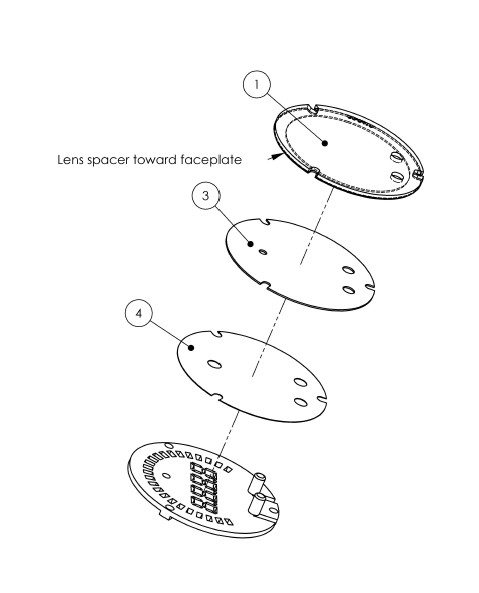

The faceplate is reversible, displaying alternative scalings on either side. Reference the Operation section of this manual for details on how to switch the display mode when reversing the faceplate. Disassembly is required to change the faceplate, flip/reverse the faceplate, or change the bezel of the gauge. The following diagram will provide familiarization with the major components of the gauge prior to beginning the procedure.

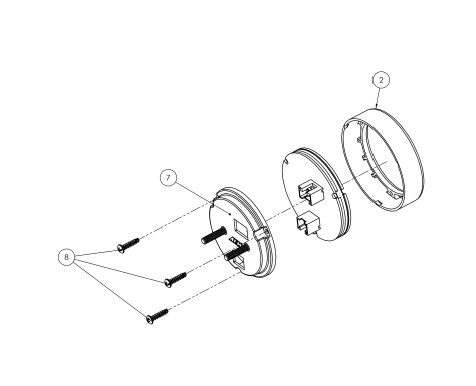

Gauge Disassembly

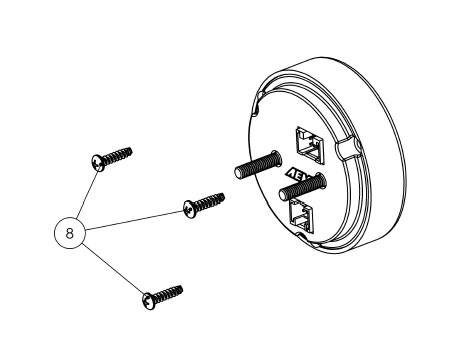

STEP 1 - Remove the three assembly screws (8) using a #1 Phillips head screwdriver. Separate the bezel (2) and cup (7) fromthe rest of the assembly. If you have purchased the optional accessory kit, the silver bezel may be replaced for the existing bezel at this time

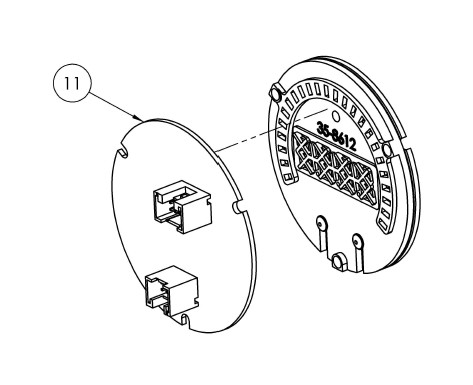

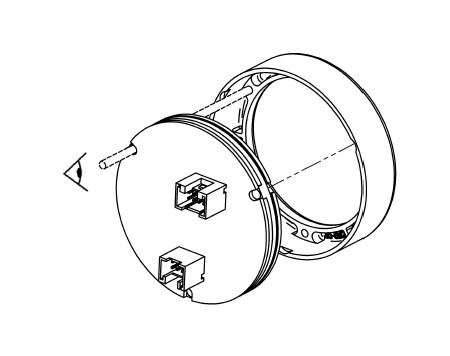

STEP 2 - Separate the PCB (11) fromthe remaining components

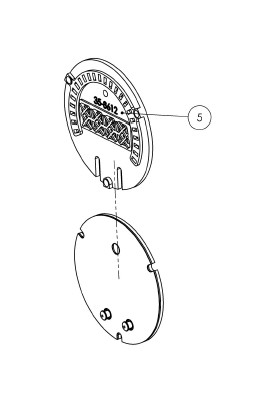

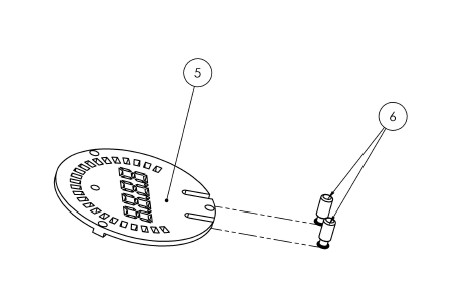

STEP 3 - Slide the light guide (5) upward to remove it, the buttons may fall out at this time - take care not to lose them

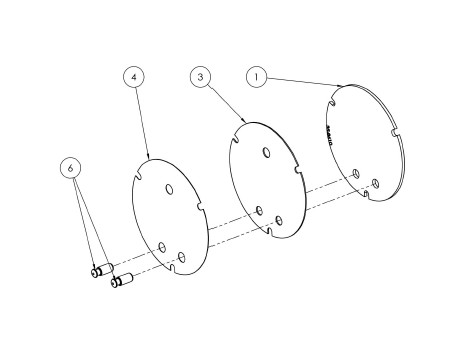

STEP 4 - As you separate the remaining components, diffuser (4), faceplate (3), lens (1), note the order in which they were assembled. The faceplate (3) may now be reversed to display an alternate scaling or replaced for a different color as included in the optional accessory kit

Gauge Assembly

STEP 1 - Place the light guide (5) on a flat surface (black side up) and slide the buttons (6) into the slots

STEP 2 - Stack the diffuser (4), faceplate (3), and lens (1) in order, over the buttons, and on to the light guide

STEP 3 - Reassemble the PCB and display stack with the bezel, making sure screw holes are aligned through the entire assembly

STEP 4 - Reassemble and tighten screws to 2 in-lb (previously assembled bezel) or 3 in-lb (new bezel). Do not over-tighten!

Gauge Installation

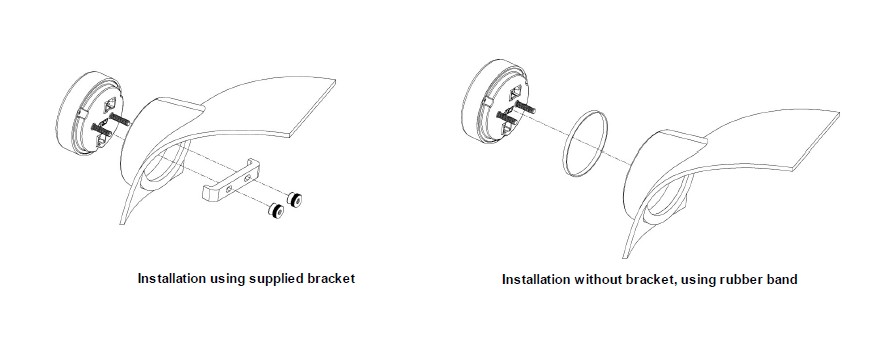

A 2-1/6" (52mm) hole is required to mount the X-Series gauge. A bracket and thumbscrews are provided to facilitate installation into a panel or gauge pod. In some cases, the gauge cup may be pushed into a mounting hole causing an interference fit strong enough to retain the gauge; the supplied rubber band may be fit to the gauge to create a tighter fit in mounting holes slightly larger than 52mm. It is, however, recommended that gauges be mounted securely using the supplied bracket to ensure they never become loose and cause a hazard during vehicle operation.

Note: The gauge is not water-proof and should not be installed in a location with exposure to water or snow. Damage caused by water ingress will not be covered under warranty.

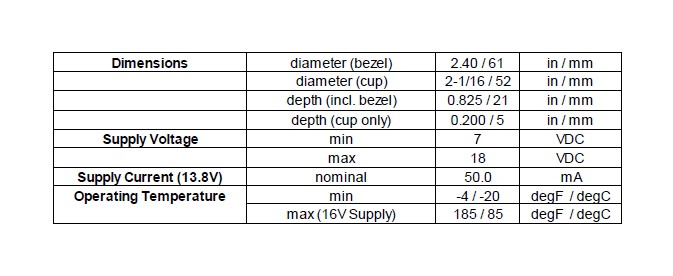

Specifications