How to Install a PA Performance Alternator - 95 Amp on your 1987-1993 Mustang 5.0L

Shop Parts in this Guide

Note : Steps 1 to 12 and 14 to 20 apply to upgrading to both the 95 and 130-Amp units. Step 13 outlines the additional modifications needed when upgrading to the 130-Amp unit.

1. Disconnect the battery negative (-) terminal from the battery and move it to the side to prevent accidental contact during the installation.

2. Remove serpentine belt. Using an 18mm socket, release the tension on the belt and remove belt from top pulleys including the alternator, idler and air conditioner. The tensioner is located on top and immediately to the right of the alternator. You may wish to leave the belt on the other pulleys until the end so you can see the proper belt path for reinstallation. If not, there is typically a diagram sticker on the radiator support.

3. Remove the cover from the air filter box. We found this made things easier.

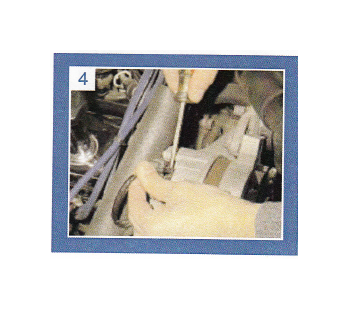

4. Gently remove the regulator plug from the alternator on the car using a flat-blade screwdriver. This plug will be reused, so be careful not to break the plastic clip.

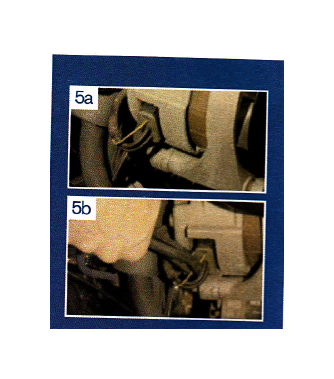

5. Locate the power output plug (two # 10 black-orange stripe wires and one #14 white-black stripe wire). This plug typically exits on the side of the alternator closest to the air box. Once you locate it, cut all three wires about 1/2" from where they go into the plug on the alternator.

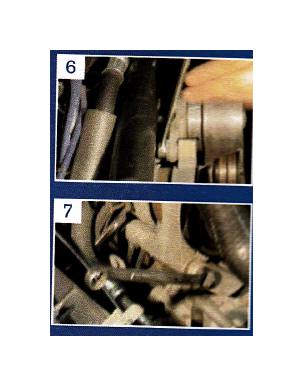

6. Remove top mounting bolt. Using a 9/16" socket, remove the one top mounting bolt from the alternator-mounting bracket. This will NOT be reused on the new alternator.

7. Remove lower mounting bolt. Using a 5/8" wrench or socket, remove the lower mounting bolt from the alternator-mounting bracket. This WILL be reused on the new alternator.

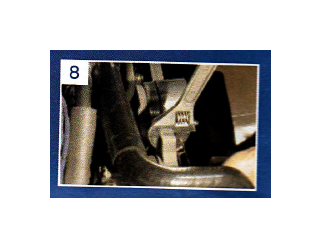

8. Wiggle the unit front to back to loosen it from the lower compression bushing. This can be done by hand or with an adjustable wrench on the top mounting bracket.

9. Gently remove the wire loom fastener from the rear of the unit (secures wires to the alternator housing) if one exists.

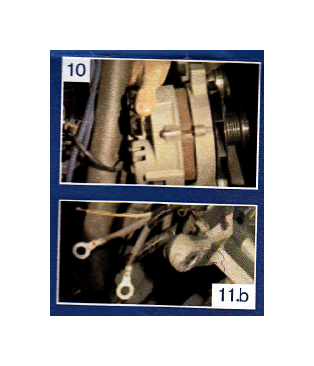

10. Remove the old alternator from the vehicle, being careful not to snag wires or damage the car.

11. Add output terminals on the three wires cut in step # 5.

a. Using a wire stripper, strip about W of the insulation from the ends.

b. Crimp and solder the terminals provided with the new alternator onto the ends of the large black-orange stripe wires.

c. Crimp and solder the in-line connector onto the small white-black stripe wire and the white wire.

d. Heat-shrink tubing has been provided for all three connections and we recommend using it to ensure protection. Use care not to shrink the tubing prematurely while soldering.

Note: If you only crimp the terminals without soldering, it will work, but as with any electrical connection, soldering is the most effective method and is what we recommend.

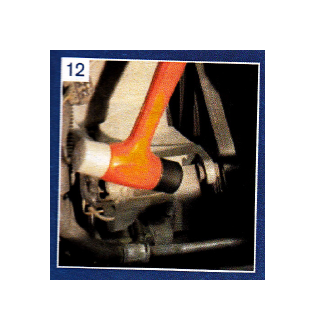

12. Move the mounting bushing using a small hammer or adjustable pliers, to allow more room for the new alternator to fit in the opening. This is a compression bushing and will snug against the new alternator when the mounting bolt is installed and tightened.

If you are upgrading to the 130-Amp unit

(add Step #13 below)

Because the 130-Amp unit has a larger frame than the other units, the alternator mounting bracket on some vehicles will need modification. If test-installation of the alternator shows interference with the mounting bracket, then proceed as described below.

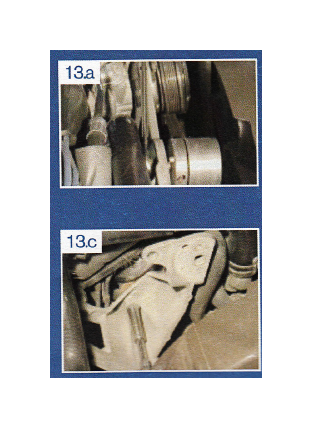

13. Remove and modify the mounting bracket:

a. Using a 19mm wrench, remove the tensioner. You will need to hold the tensioner from the front to keep the locating pin engaged and prevent the unit from spinning.

b. Loosen and remove the top mounting bolt holding the air pump. It is not necessary to remove the air pump itself.

c. Remove the three mounting bolts holding the bracket on the engine. The top and bottom bolts require a 9/16" socket while the side bolt requires a W socket. You will need an extension and/or a universal joint to access these bolts - but they will come out without any hose removal, etc.

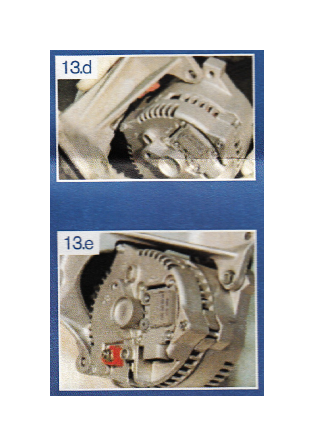

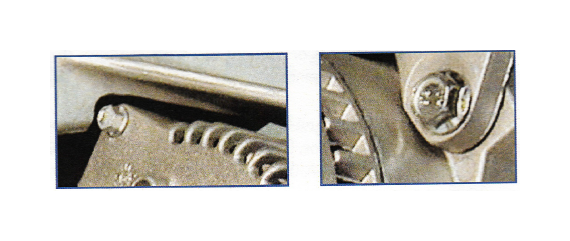

d. Mark the mounting bracket as shown in the picture and remove material in those areas with a dremel tool or grinder. In some cases the lower side of the top mounting-hole area will also need modification. Use care when grinding to avoid getting metal fragments on the engine, in the alternator or anywhere else that metal fragments should not be. As always, wear eye protection!

e. Grind bracket as shown in the pictures below. Test-fit the alternator to ensure it does not contact the mounting bracket anywhere. Always be careful not to drop the alternator on the ground, which could result in permanent damage.

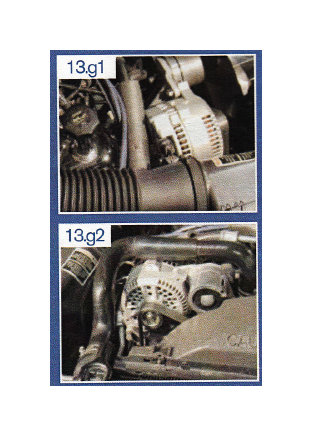

f. Reinstall the mounting bracket. Tighten all three bolts, being careful not to over-tighten.

g. Reinstall the air-pump bolt and tensioner. Use care to be sure the bolt is properly seated in the tensioner while tightening.

Note: On all alternator upgrades: Due to the significant increase in available power output you MUST upgrade the main power wire. The stock wire cannot carry all of the available current safely (recommended on the 95 amp kits - required on the 130 amp kits) PA-Performance offers a complete kit.

Common installation continued

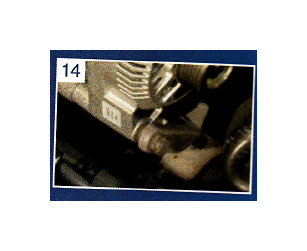

14. Place the alternator in the vehicle. Reinstall the lower mounting bolt finger tight. Install the new (metric) top mounting bolt finger tight. Do not fully tighten either bolt at this time.

15. Reinstall the serpentine belt in the original position (removed in Step # 2). We have found it easiest to install the belt on the air conditioner pulley last.

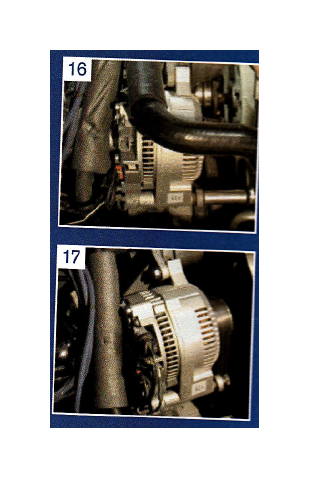

16. Tighten mounting bolts. With belt tension on the alternator, you can now finish tightening the lower mounting bolt with a 5/8" socket and then the top mounting bolt with a V2" (or 13mm) socket. Be careful not to over-tighten these bolts.

17. At this point, stop and look at the unit, wires and hoses. Be sure that nothing is pinched or in a position to be pinched. Using care here will eliminate problems later.

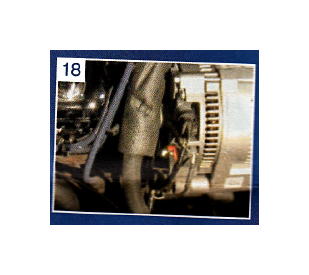

18. Reconnect terminals. Locate and connect BOTH large black-orange stripe wires to the battery stud on the rear of the alternator using a 10mm wrench. It is VERY IMPORTANT that this not be over-tightened as internal damage could result and void the warranty. Locate the small stator plug and securely connect it to the new unit. Finally, reconnect the regulator plug disconnected in Step #4.

19. Connect the battery (-) wire disconnected in Step # 1, being careful not to over-tighten the bolt. This would be a good time to clean any corroded battery connections or replace any cracked or damaged battery wires. Since the new alternator produces more amperage, corrosion may cause undue heat or prevent you from realizing the full potential of the new unit. If the air box cover was removed, reinstall it now.

Note: due to the significant increase in available power it is strongly recommended that before starting the engine with the new alternator in place you fully charge (or verify) the battery.

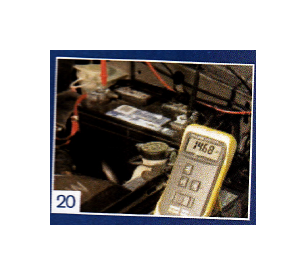

20. Start the engine. Using a DC volt meter, measure the voltage across the battery terminals (consult the volt meter user manual for instructions if you are unfamiliar with the use of this instrument). With the engine running you should be charging over 12.5 volts at idle. This will assure that the alternator is charging.

Note: In a stock application, the OEM belt will work on the new 3G alternator. If underdrive pulleys have been installed or if the pollution pump has been removed, you will need to select a belt which keeps the tensioner in the "normal" position. We do not recommend changing the pulley on the new 3G alternator. Modifying the unit in any way - changing the pulley or loosening the thru-bolts - will void the warranty.

That completes the steps we took to install our new unit. If you have any questions, the pictures and instructions are available on our web site - and you can e-mail us with any observations or questions from your own experience.