CDC Mustang Louvered C-Pillar Scoops ('05-'11) - Unpainted - Installation Instructions

Installation Time

60 minutes

Tools Required

- Masking Tape

- Soft Clean Rag

- 80-120 grit sandpaper

Shop Parts in this Guide

Installation

Prepping Scoops:

1. Sand area to be taped on the part with 80-120 grit sand paper.

2. Clean with supplied alcohol swabs. Allow time to dry.Caution:Proper ventilationshould be used when handling all solvents. Inhalation and direct contact with skin or eyes should be avoided.

3. Apply supplied Adhesion Promoter. Allow time to dry.Note:Adhesion Promotermay discolor paint, only apply where needed. The drying time is generally 30 - 45 seconds but may depend on conditions. Tape should be applied within 1hour of applying Promoter, in a dust free environment.

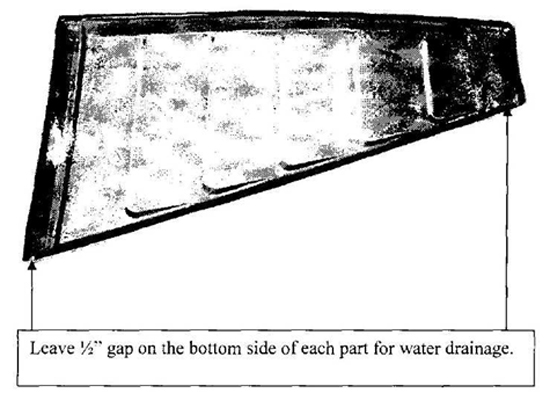

4. Apply 3M Acrylic Foam Tape. Lay parts face down on a soft surface, to avoid scratches. Cut tape with a razor blade where a continuous piece is not possible.Note:It is recommended that the temperature of the part be 60 -110°F at thetime of application.

5. Apply even pressure around part to set tape. As a general rule, a minimum of 15 PSI should be used.Note:Immediately after the tape is applied about 60% of thebond strength is achieved. After 24 Hrs approximately 75%- 80% is achieved. After 72 Hrs 95% bond strength is achieved.

Installing Side Scoops

1. Thoroughly clean area where bonding tape will contact vehicle and wipe with isopropyl alcohol to remove wax.It is imperative that any wax be removed from the vehicle at the tape contact area for proper adhesion of Side Scoop.

2. Use locating tab at rear of Scoop to align Scoop front to back (Tab fits between glass and sheet metal). Place Scoop in mounting position and mark corners with masking tape.

3. Once desired location has been marked, remove Scoop and peel all red backing from the bonding tape. Install Scoop to vehicle using masking tape as guide.

4. Press Scoop edges firmly to car to set the Bonding Tape.

5. Repeat process for other side of vehicle

Installation instructions provided by CDC