How to Install Centerforce Dual Friction Clutch Kit on your Mustang

Shop Parts in this Guide

BELLHOUSING ALIGNMENT IS CRUCIAL FOR PROPER CLUTCH FUNCTION AND RELIABILITY OF THE RELATED COMPONENTS. DUE TO MANUFACTURING TOLERANCES OF ENGINE BLOCKS AND BELLHOUSINGS, IT IS POSSIBLE FOR THE TRANSMISSION CENTERLINE AND CRANKSHAFT CENTERLINE TO BE MISALIGNED. THE RESULT OF THIS MISALIGNMENT MAY BE HARD SHIFTING, PILOT BEARING WEAR, TRANSMISSION MAIN SHAFT BEARING WEAR AND FAILURE OF CLUTCH DISC HUB.

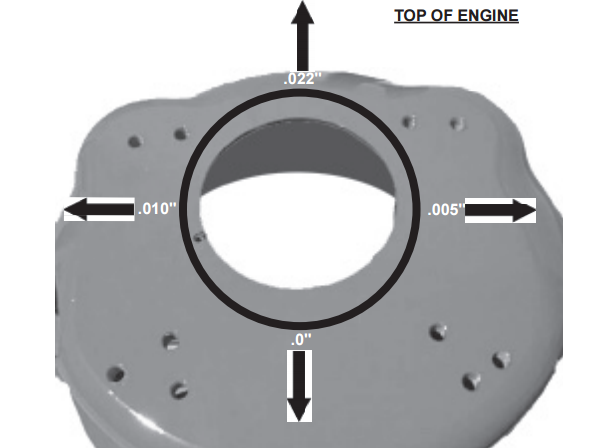

FIRST CHECK BELLHOUSING FOR BORE CONCENTRICITY. INSTALL MAGNETIC BASE TO FLYWHEEL OR PRESSURE PLATE, THEN INSTALL THE INDICATOR TO MEASURE THE BELLHOUSING BORE (SHOWN ABOVE). ROTATE THE CRANKSHAFT AND MARK DOWN THE INDICATOR READINGS (MARKING THE BELLHOUSING WORKS WELL). THE MAXIMUM OUT OF CONCENTRICITY IS .005".

NEXT, THE BELLHOUSING FACE SHOULD BE CHECKED FOR PARALLELISM TO THE BACK OF THE BLOCK. INSTALL THE INDICATOR (AS SHOWN ABOVE). ROTATE THE CRANKSHAFT AND MARK DOWN THE READINGS (BE SURE TO PUSH THE CRANKSHAFT AGAINST THRUST BEARING FOR ACCURATE MEASUREMENT). THE MAXIMUM OUT OF PARALLELISM IS .002"

TO CORRECT OFF-CENTER CONDITION, SELECT THE OFFSET DOWEL PIN PAIR THAT IS CLOSEST TO ONE-HALF OF THE INDICATOR READING (I.E., IF READING IS .016", 1/2R=.008" USE .007" DOWELS. IF READING IS .024", 1/2R=.012" USE .014 DOWELS).

EXAMPLE THE BELLHOUSING WAS OFFSET TOWARD TOP OF ENGINE AND SLIGHTLY TO THE LEFT (AS VIEWED FROM BEHIND). TO ALIGN THE BELLHOUSING, INSTALL TWO .014" OFFSET DOWEL PINS WITH THE MAXIMUM OFFSET POSITIONED ROUGHLY AT THE 5 O'CLOCK POSITION.