How to install a Cervini's Ram Air Type IV Hood on your 2010-2012 GT Mustang

Shop Parts in this Guide

Installation

Notice: Install new, unpainted parts according to these instructions!

Then remove parts, paint them and re-install.

Painted or Altered Parts are Non-Refundable!

Step 1

Remove the factory hood from the car, then remove the striker bar from the factory hood.

Step 2

Bolt the new hood to the factory hinges using the new hardware provided with the new hood. Adjust hood until proper alignment with matching panels is achieved.

Step 3

Install factory striker bar with medium strength Locktite® to your new hood. Adjust primary latch if needed until striker bar aligns with the latch. Make sure when the hood is closed you can hear the striker bar “click” into the latch.

Step 4

After you hear it “click”, test it to be sure it is working properly by grabbing the front edge of the hood and slowly pulling upward with steady even pressure. If the hood opens, it’s not adjusted properly; Repeat Step 3 until hood cannot be pulled open after it’s closed.

WARNING: MAKE SURE THE SAFETY CATCH IS WORKING PROPERLY!

Step 5

To ensure the safety catch is working properly, close the hood, pull the hood release from inside the car and the hood will partially open. Slowly pull up on the hood while fi rmly shaking the hood up and down. If the hood opens without pulling the safety catch lever then the latch needs to be re-adjusted. The safety catch prevents the hood from opening in the event that the primary latch fails.

Step 6

Locate the rubber hood stoppers found on the radiator support. Adjust upward until they apply a small amount of pressure to the underside of the hood when it is closed. This will prevent the hood from shaking or rocking. Re-install the weather stripping on the rear of the hood. You will need to cut it so that it does not cross over top of the windshield washer squirters as shown in fi g.C.

Step 7

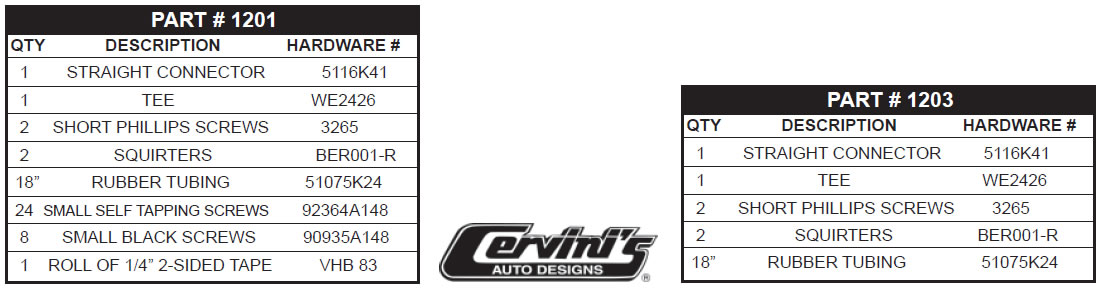

Install the windshield washer squirters as shown in fi gure A. Then cut the factory squirter hose before the fi rst squirter connection as shown in fi g. B. In your hardware packet we have supplied you with an 18” length of rubber tubing and some connectors, add the straight squirter connector and 14” of rubber tubing where you cut the factory squirter hose. Then run the squirter hose through the weather stripping and connect it to the squirter as shown in fi g.C.

Step 8

After all adjustments have been made, apply Locktite® to the bolts that secure the latch bar to the hood. You may need to bend the squirters into position.

Installation of Billet Inserts for Hood #1203

Step 9

Installing the drip pans: The inside of the drip pans are visable through the billet insert and need to be painted fl at or semi gloss black. After the hood and drip pans have been painted, align the drip pan with the heat extractor opening in the hood. Use the supplied small silver phillips screws to screw the drip pan to the under side of the hood through the pre-drilled holes in the drip pans as shown in fi g.D. The small silver screws will tap themselves into the hood. (Tighten the screws with a screw driver only. Using a powered screw driver will cause the holes to strip.)

Step 10

Installing the billet insert trim rings: Included in the hardware packet is a roll of 3M double sided tape. After the trim rings have been painted, install the 3M double sided tape along the inside edge of the trim rings as shown in fi g.E. After the hood has been painted remove the double sided tape backing from the trim rings and place them in the opening located in the rear of the hood as shown in fi g F. The back of the trim rings are marked L for left side and R for right side. Be sure to center the trim rings in the opening. Firmly press on the edges of the trim ring to secure it to the hood.

Step 11

Installing the billet inserts: Lay the billet inserts in the trim rings. Align the pre-drilled holes in the billet insert with the pre-drilled holes in the trim rings. Use the supplied small black screws to secure the billet grille to the trim ring through the pre-drilled holes as shown in Fig.G.

URETHANE PAINTING INSTRUCTIONS

VERY IMPORTANT: The following painting procedures MUST be followed EXACTLY for PROPER ADHESION and to prevent fi sh eyes.

1. To remove any mold release contaminants, clean the back of the part fi rst. Using 2 new clean rags, saturate the fi rst rag with plastic prep cleaner* and begin cleaning. Then use the second rag to remove the prep cleaner. Continuously fold both rags to their clean sides during the process. Use 3 sets of new rags throughout the process. This prevents mold release contaminants from transferring to the painted surface.

2. Repeat step one on the front of the part.

3. Rinse the part with water. Apply a generous amount of Ajax® or sand fi x* to a red scuff pad* (3M Scotch Brite Brand) and scrub the surface to be painted THOROUGHLY (especially where the 2-sided tape is installed, on the back side of the part, and all the hard to reach areas). Then rinse with water and dry. The scrubbed surface should be dull. If any shiny spots show, repeat the process on those areas.

4. Using another set of clean new rags, again clean the surface to be painted with plastic prep cleaner.

5. Spray the surface to be painted with adhesion promoter* including the areas where the 2-sided tape is installed (follow the instructions on the can for application and drying time).

6. Apply 3 to 4 coats of urethane primer* with fl ex additive* (follow the instructions on the can for application and drying time).

7. Wet sand primer with 600 grit sandpaper. Be careful not to sand through the primer. If you do, you MUST clean those areas with plastic prep cleaner, apply adhesion promoter and prime. Once the primer has dried, wet sand the areas that were touched up. Your surface is now ready for paint.

* These items can be purchased at any auto body supply store.

Note: Make sure you PRIME and PAINT the areas where the 2-sided tape is used as you would if it was the outside of the part. The tape adheres best when it is applied to a painted surface.