How to install Comp Cams Phaser Limiter Kit on your 2005-2010 GT Mustang

Shop Parts in this Guide

Installation

Read This Pre-installation Guide Before Installing Kit !!!!!!!

Ford 4.6L and 5.4L 3-valve engine cam phasers, how they work, their limitations, and how COMP uses them for making more power

What are cam phasers?

Ford’s cam phasers are specially designed, computer controlled cam gears that have the ability to adjust camshaft position while the engine is running. They are used on all 2005 and newer, 3-valve Ford modular engines. Since the modular engine uses two camshafts, one for each side of the engine, two cam phasers are used per engine.

How do they work?

Engine oil is pressure fed through a series of passageways in the cylinder heads and camshafts, out to the cam phasers. The engine computer controls a pair of solenoids that adjust this oil flow into, and out of, a series of chambers inside the cam gears. Located inside these chambers are vanes, attached to a free-floating central hub. The hubs are directly attached to the camshafts, and as oil is allowed into and out of these chambers, the position of the cam can be retarded up to 60 crankshaft degrees.

Why did Ford put them in the engine?

Ford’s primary reason for using cam phasers was to increase the engine’s efficiency by reducing its pumping losses. Basically, when the cams are retarded 20-40 degrees, during part throttle engine operation, it takes less power to turn the engine over. This helps to increase the engine’s fuel efficiency, but an additional power benefit is also realized by being able to position the camshafts for maximum power, regardless of what rpm the engine is running at. This results in an engine that makes more torque and horsepower and extends the high rpm power-band by an additional 800-1000 rpm.

Why should I modify the cam phasers with COMP’s limiter kit?

If there is a downside to the cam phasers as designed by Ford, it is that they have such a wide range of movement. Since the cams can theoretically be retarded by up to 60 degrees, there is very little piston to valve clearance in the engine. This minimal piston to valve clearance limits us to fairly small cam profiles with very little overlap; not the best for making maximum power or achieving an aggressive idle sound.

What does COMP’s cam phaser limiter kit do?

COMP’s Cam Phaser Limiters replace a plate on the back side of the factory cam phaser. These limiter plates are made with posts that extend into the cam gear’s oil chambers. These posts take up excess volume that would normally be used by the factory cam gear for movement. By installing COMP’s cam phaser limiters, the cam design window opens up, allowing you to install big, powerful camshafts with safe piston to valve clearances. At the same time, by keeping up to 20 degrees of movement available, all of the wide-open throttle benefits of the cam phasing can still be retained. The normal maximum retard the cams see at wide-open throttle is only around 9 degrees with factory programming.

Why can’t I just reprogram the ECU to limit cam phaser movement?

Since Ford’s factory engine computer is fully programmable, the question arises as to why you can’t simply program in the limits and not bother with mechanically limiting the cam phasers. Theoretically you could do that, but a problem arises if something happens that would cause the engine’s rpm to shift faster than the cam phaser controls can react to. For example, if you ever missed a shift, broke a driveline part, did a clutch dump on a sticky set of slicks, or anything that could for a split second cause the cam phasers to get out of their programmed limits, the valves could crash into the pistons. By mechanically limiting the maximum movement of the cam phasers, total engine safety is assured when running big performance cams in these engines.

Do I have to reprogram my engine’s computer after installing COMP’s Cam Phaser Limiter Kit?

Yes, you MUST have your engine’s computer reprogrammed for the engine to operate properly after installing the cam phaser limiters. The Ford factory computer does a diagnostic sweep test of the cam phasers upon start-up. If the computer cannot get the cam phasers to reach their programmed maximum limit, an error mode occurs. The engine will continue to run, but the cam phasers will not function properly. The guidelines for reprogramming are simple; just make sure that the maximum retard amount entered for any of the cam phaser tables in your tuning software does not exceed 20 degrees.

What camshaft profiles has COMP developed to work with the Cam Phaser Limiter Kit?

The Cam Phaser Limiter Kit unlocks the door to safely use much more powerful camshaft grinds. COMP Cams® spent a tremendous amount of engine dyno time testing and developing these designs for maximum power, torque and reliability. Three stages of cams are currently available for naturally aspirated engines, as well as an additional three stages of cams specifically designed for blower equipped engines. Along with these premier camshaft sets, a complete line of valve springs and retainers are available that round out the matched performance package.

INSTALLATION INSTRUCTIONS

Note: These instructions give a very basic overview of what is required to install the COMP Cams® Ford 3Valve Cam Phaser Limiters. They in NO WAY replace the VERY specific factory instructions for removing and replacing the camshafts. Failure to follow the specific factory recommended instructions for removal and replacement of the camshafts during the installation of these cam phaser limiters can lead to incorrectly timed camshafts and result in engine damage.

MECHANICAL

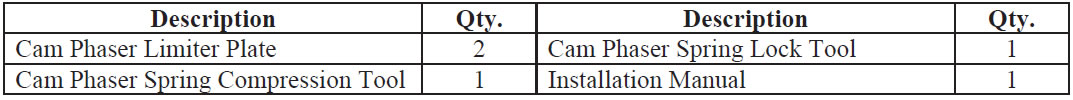

Step 1: We are going to show you the installation basics on the passenger side of the engine; simply repeat the same procedure on the driver’s side of the engine.

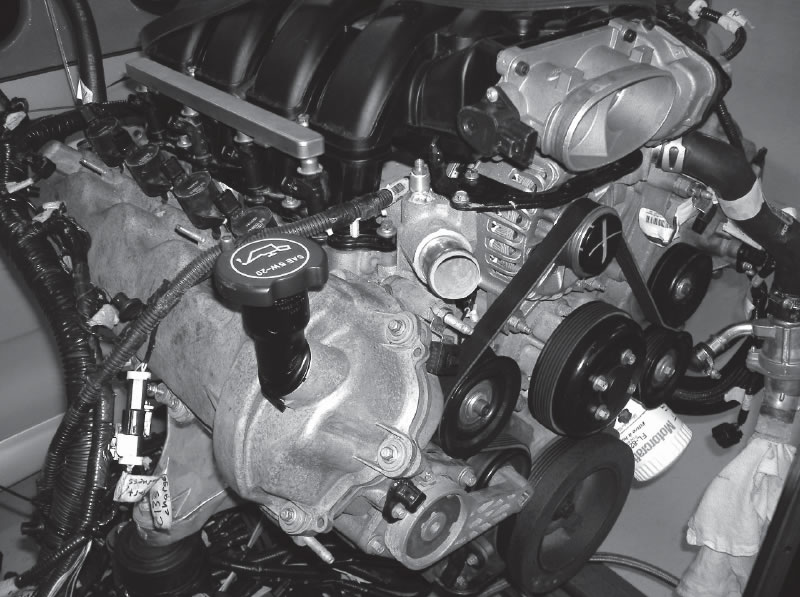

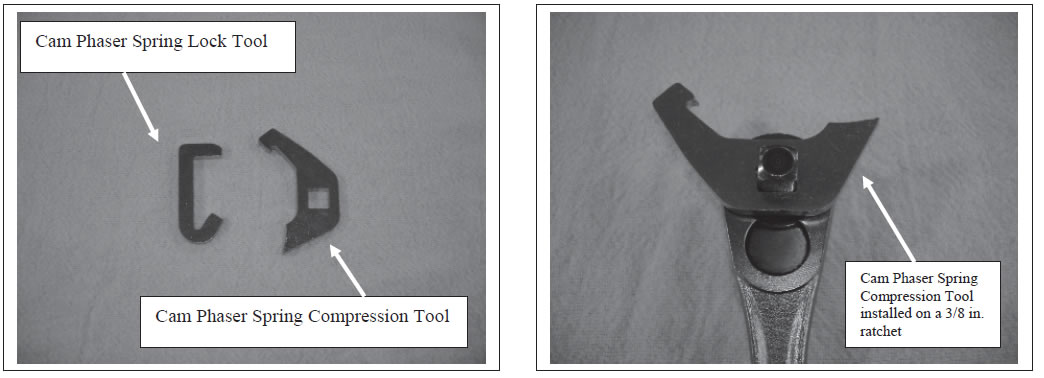

Step 2: Special tools are required to properly disassemble the cam phasers. We designed and provided these tools as part of the kit. The Cam Phaser Spring Compression Tool is designed to snap onto a standard 3/8” ratchet.

Step 3: Before you begin to remove the valve train from the engine, remove the cam position sensor. If the sensor is not removed, the Cam Phaser Spring Lock Tool will hit it when the engine is turned over. Reinstall the cam position sensor before starting the engine!

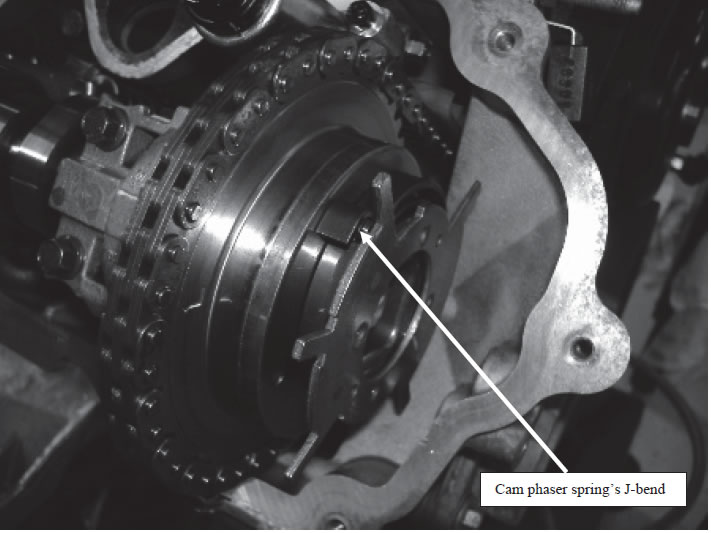

Step 4: Take the spring compression tool and hook it on the spring’s J-bend.

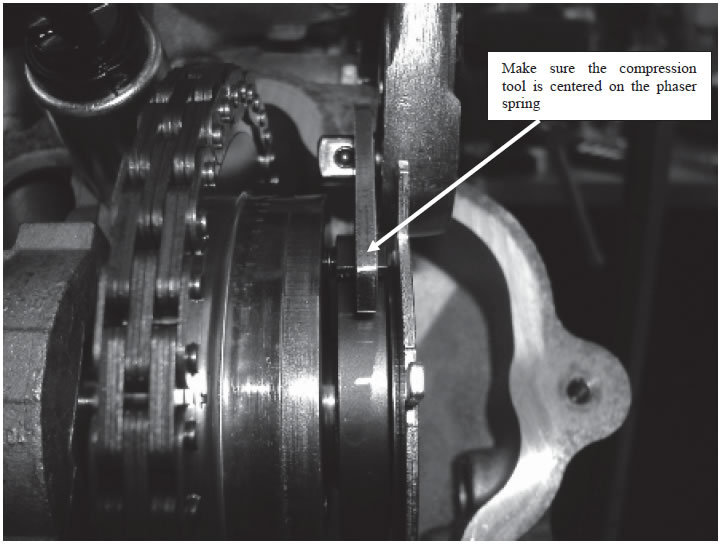

Step 5: Compress the spring, then insert the spring lock tool.

Here is the spring lock tool, properly locked in place.

WARNING!!!!! Once the Cam Phaser Limiters have been installed, you MUST remove the spring lock tool before rotating or starting the engine! The spring lock tools are not meant to be left on, they are for installation purposes only!

Step 6: Once the cams have been removed from the engine, remove the cam phasers and place them on a clean workbench.

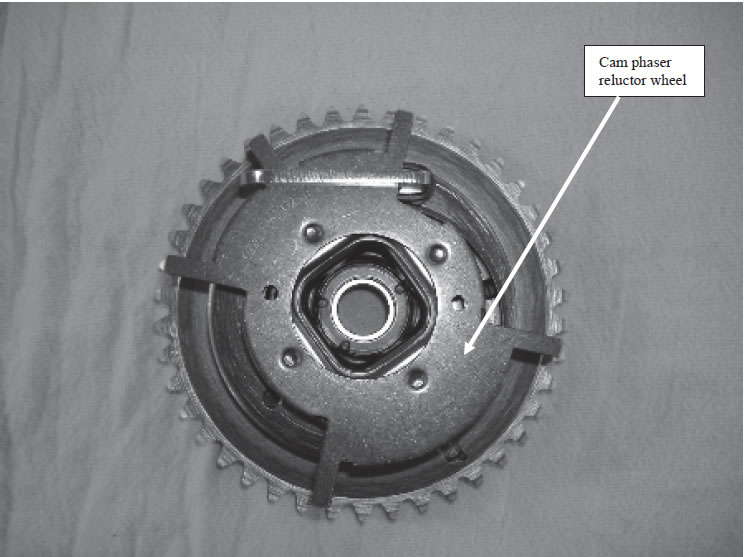

A word of caution, be very careful of the reluctor wheel. The only thing that holds it onto the cam gear at this point is a press-fit on the three rivets at the center of the hub. The reluctor wheel can be very easily bent or damaged if the cam phaser is handled roughly or dropped.

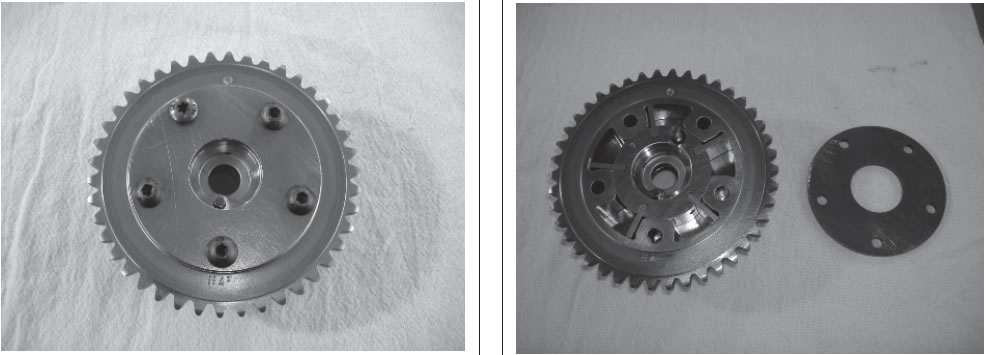

Step 7: Turn over the cam phaser and remove the five bolts holding the back cover on.

Be very careful of the cam phaser’s parking spring assembly; it falls out with little effort.

If the spring falls out accidentally, the photo below shows you the order it goes back in.

Step 8: Insert the cam phaser limiter into the cam phaser. It only goes in one way and it does not matter how it is clocked.

Step 9: Insert the bolts and torque to 85 in. lbs. Remember to take note that one bolt is longer than the others. This long bolt goes through the back of the cam gear and acts as a post for the cam phaser spring’s J-hook to attach onto. Make sure this long bolt is inserted into the correct hole that positions itself properly in relation to the spring’s J-hook.

Important Installation Notes!!!!!!

- Reinstall the cam position sensors before starting the engine!

- WARNING!!!!! Once the Cam Phaser Limiters have been installed, you MUST remove the spring lock tool before rotating or starting the engine! The spring lock tool is not meant to be left on, it is for installation purposes only!

COMPUTER TUNING

You MUST reprogram your engine’s computer after installing COMP’s Cam Phaser Limiter Kit!!!!!

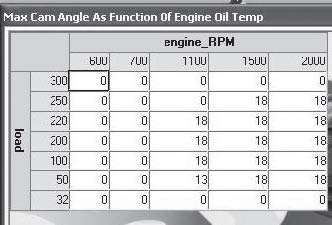

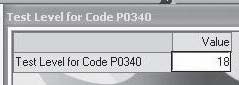

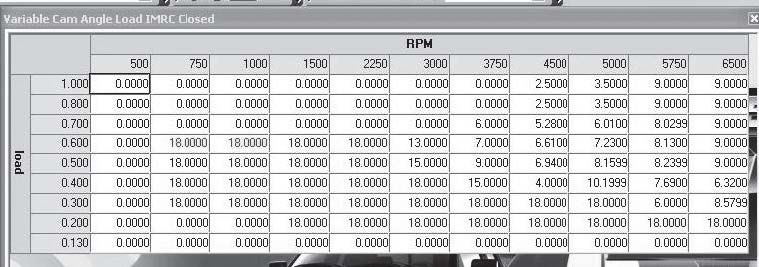

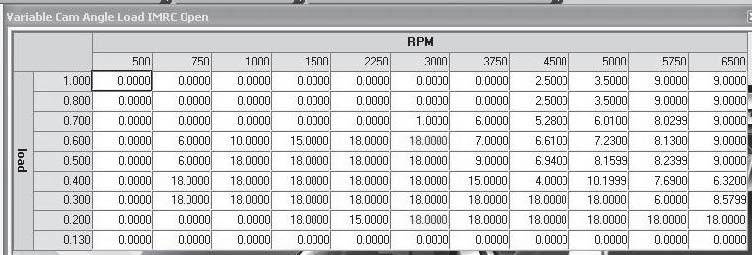

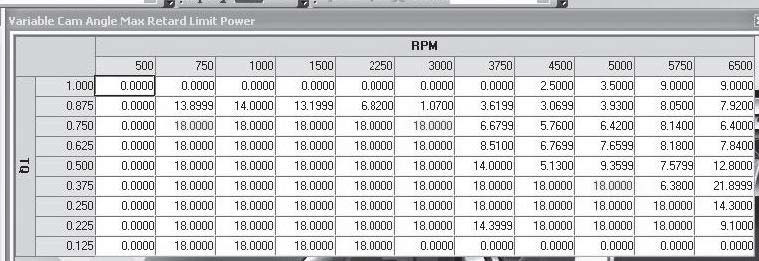

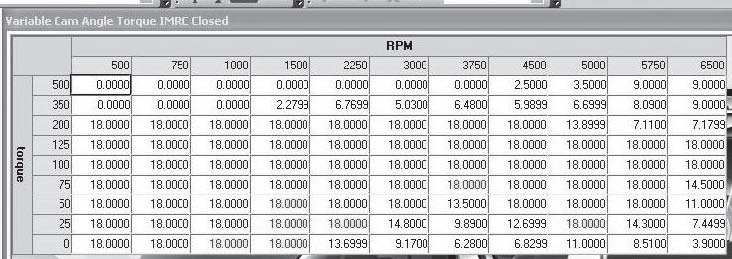

Yes, you MUST have your engine’s computer reprogrammed for the engine to operate properly after installing the cam phaser limiters. The Ford factory computer does a diagnostic sweep test of the cam phasers upon start-up. If the computer cannot get the cam phasers to reach their programmed maximum limit, an error mode occurs. The engine will continue to run, but the cam phasers will not function properly. The guidelines for reprogramming are simple; just make sure that the 7 tuning menus related to cam phasing do not have any values listed above 20 degrees.

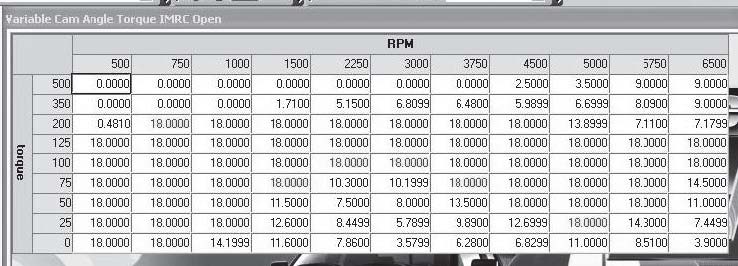

Attached are seven menu screenshots of a popular tuning software program used during our dyno testing. These screenshots are provided to help your tuner get an idea of what menus need to be accessed and what areas need to be adjusted for proper cam phaser operation. The values shown are basically the stock Ford factory cam timing related tables with settings that were originally above 18 degrees, reduced down to 18 degrees. This worked well for us during our testing, but we want to stress that ultimately, it is your responsibility to ensure that the tuning done for your particular engine works properly.

Menu #1

Menu #2

Menu #3

Menu #4

Menu #5

Menu #6

Menu #7