Top Sellers in Mustang

How to Install a Corsa Sport Quad Tip Axleback Exhaust in your 2013-2014 Mustang GT500

Installation Time

2 hours

Tools Required

- Safety Glasses

- 3/8” Ratchet

- Torque Wrench

- Soapy Water Solution

- 13mm Socket

- 15mm Socket

- 18mm Socket

Shop Parts in this Guide

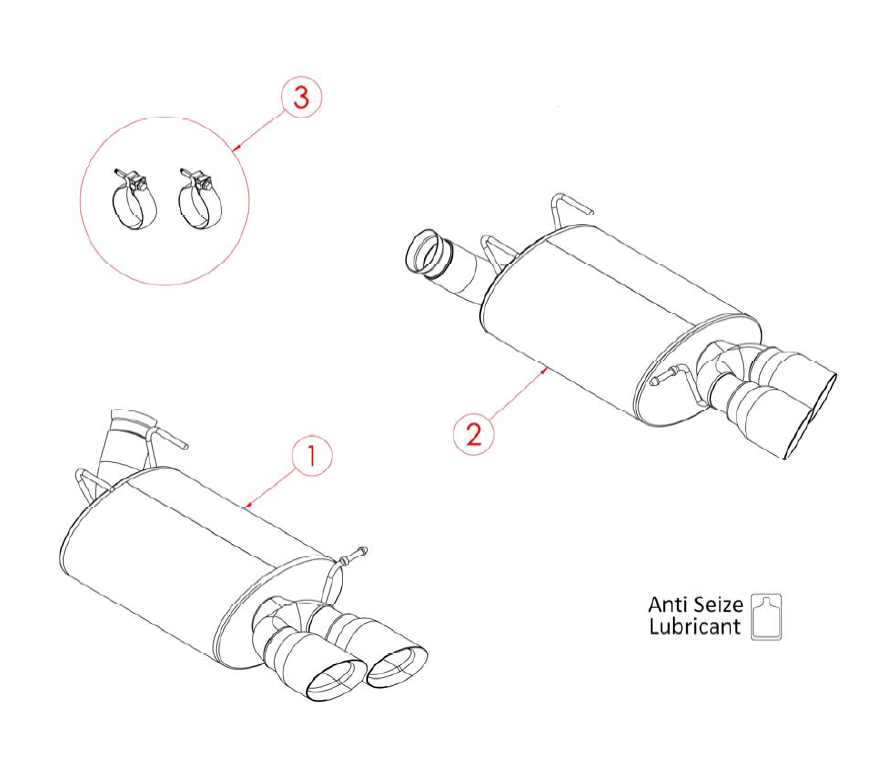

Please confirm that all parts are present before beginning the factory exhaust system removal and CORSA exhaust system installation.

Bill of Materials:

1 - Driver Side Rear Muffler Assembly (20MU2054)

2 - Pass Side Rear Muffler Assembly (20MU2055)

3 - Hardware Kit: (20MU7013)

• (2) 70mm Spherical Clamps

Factory Exhaust System Removal:

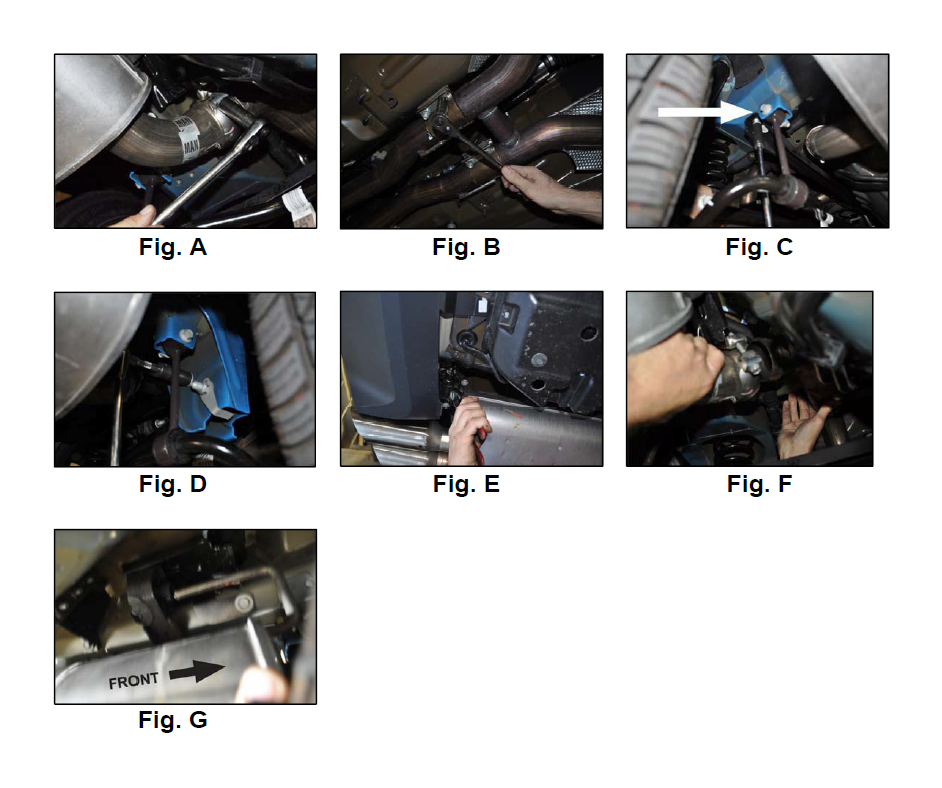

1. Using a 13mm socket and a 3/8” ratchet, loosen the two spherical clamps at the inlet of each of the factory rear mufflers. (See Fig. A)

2. Using a 15mm socket and ratchet, loosen the four nuts on the factory sleeve clamps located just after the factory H-pipe assembly. (See Fig. B)

3. Using a 15mm socket and ratchet, remove the two bolts that secure the driver side of the panhard bar to the chassis. (See Fig. C) Using an 18mm socket and ratchet, loosen, but do not remove, the bolt securing the passenger side of the panhard bar to the chassis; (See Fig. D) this will allow the bar to rotate freely.

Rotating the bar downward on the driver side will create additional room, which allows the driver side rear muffler to be removed with less difficulty.

4. Remove the driver side rear muffler hanger using grommet pullers or a similar device. (See Fig. E)

NOTE: The use of a soapy water solution may aid in the removal and later installation of the hangers in the rubber isolators.

5. Pull the driver side axle pipe away from the clamp joint at the rear muffler inlet. (See Fig. F) While holding the axle pipe out of the way, move the muffler forward in the chassis to remove the two front hangers from the grommet. (See Fig. G) Carefully remove the muffler from the vehicle.

6. Repeat steps 4-5 for the passenger side. This completes the removal of the factory system.

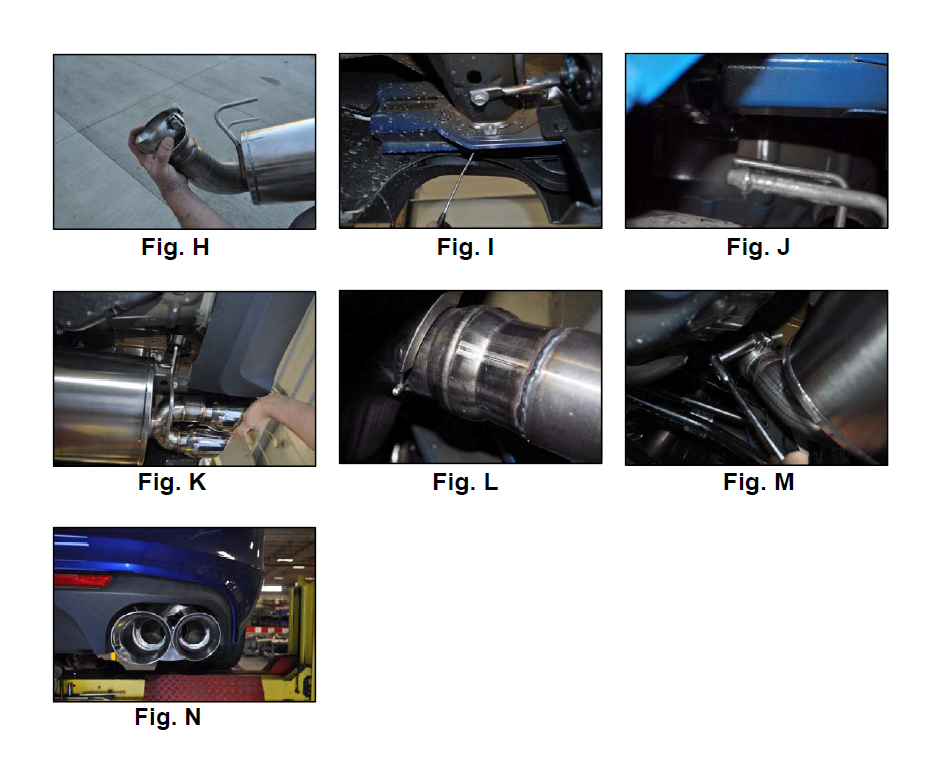

Factory Exhaust System Removal Pictures:

Installation of CORSA Exhaust System:

NOTE: Apply the anti-seize lubricant (supplied) to the threads ONLY of all the clamps and flange bolts. Failure to follow this procedure can cause nuts to seize on clamps and otentially destroy threads. After applying anti-seize lubricant, be sure to thoroughly clean your hands, as lubricant will tarnish stainless steel. All clamps should be tightened using a properly calibrated Torque Wrench. Using an air impact gun will damage the clamp and reduce its ability to effectively seal the joint. It may also cause the joint to separate, thereby causing damage to your exhaust system and to your vehicle.

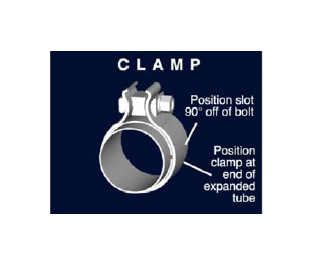

NOTE: Align all clamps so that the center of the clamp bolt is 90 degrees from the notch in the pipe. (See Fig. CLAMP)

1. Remove all exhaust system components from shipping carton, including the two supplied clamps.

2. Locate the passenger side muffler assembly and one of the spherical clamps. Align the clamp onto the muffler inlet as shown, so that it is accessible when installed on the vehicle. (See Fig. H)

NOTE: Use caution to avoid hitting the tips on the metal brace above the tip cutout in the rear valence while performing the following steps. (See Fig. I)

3. Insert the two front hangers into the factory grommet, and then carefully move the passenger side muffler rearward in the chassis to fully seat both front hangers. (See Fig. J)

4. Insert the rear muffler hanger into the grommet as shown. (See Fig. K) With the spherical clamp in place, align the passenger side muffler inlet flare to the mating form on the factory axle pipe, and snug the clamp using a 13mm socket and ratchet. (See Fig. L & M)

5. Repeat steps 2-4 for the driver side rear muffler assembly.

6. Rotate the panhard bar back up into the installed position, and install the two bolts on the driver side with a

15mm socket and ratchet. Next, tighten the nut on the passenger side using an 18mm socket and ratchet.

(See Fig. C & D from the REMOVAL section) Tighten the nut and bolts to factory specs.

7. While holding the over axle pipes in the proper position, tighten the 15mm nuts on the factory sleeve clamps using a 15mm socket and ratchet. Torque the nuts to 45 ft-lbs. (See Fig. B from the REMOVAL section)

8. Align the exhaust tips in the bumper opening as shown. (See Fig. N) While holding each muffler in place, tighten the 13mm nuts on the spherical clamps to 21 ft-lbs.

9. Visually inspect the exhaust system position, clamp orientation, and exhaust pipe clearance. Make any necessary adjustments at the slip joints. Verify clearances to all underbody components.

10. It is STRONGLY SUGGESTED that all clamps be checked and re-tightened, if necessary, to the recommended torque after initial road testing of the vehicle, as thermal cycling has occurred on the system.

Please wait until system has fully cooled to perform this step.

NOTE: During cold weather start-ups, you may experience an exhaust sound that is

deeper and louder in tone than usual. This is temporary and will diminish to normal levels once your engine has reached its normal operating temperature.

NOTE: Immediately following the installation of your exhaust system, you may experience a trace of smoke after initial start-up. DO NOT be alarmed. The smoke is caused by the burning of a small amount of forming oil residue used in the manufacturing process.