Top Sellers in Charger

How to Install Flowmaster American Thunder Cat-Back Exhaust (94-97 GT, Cobra) on your Ford Mustang

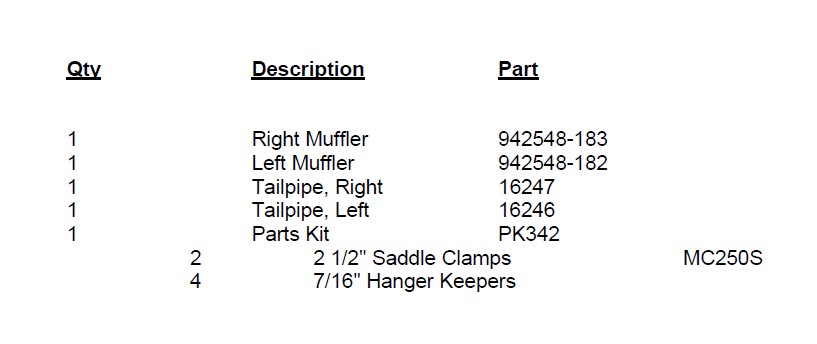

Shop Parts in this Guide

Removal:

1) Disconnect the negative side of the battery cable. Raise the vehicle up on a hoist or rack to working height. If you do not have access to a hoist or rack raise the vehicle and support securely with jack stands.

2) Separate the steel tailpipe hangers from the rubber mounts at the rear of each tailpipe. A lubricant may ease removal.

3) Using a hacksaw or sawsall, cut the stock tailpipes off, approximately 2” behind the muffler case.

4) Remove stock tailpipes from the vehicle.

5) Support the stock mufflers with stands.

6) Separate the steel muffler hangers from the rubber mounts at the rear of each muffler. A lubricant will usually ease removal.

7) Remove the two nuts at the muffler to catalytic converter connections.

8) Remove stock mufflers from the vehicle.

Installation:

1) Before installing anything, prep the clamps supplied in the hardware kit by removing the nuts, and applying a thick lubricant such as white grease or anti-seize to the threads.

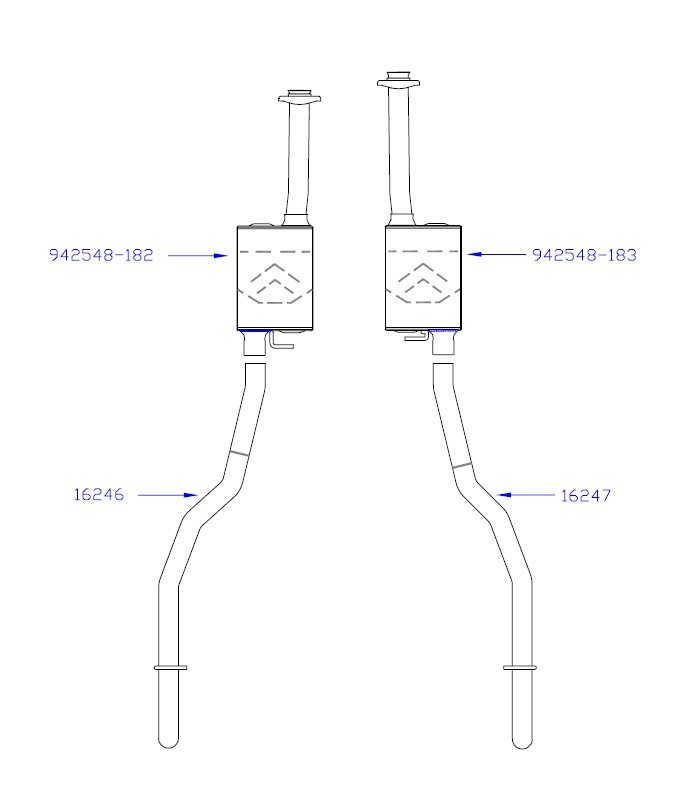

2) Position muffler #942548-183 into the stock location on the right side of the vehicle. Slide the flange on the pipe up to the flange on the head pipe and reinstall the stock nuts onto the studs. Connect the hanger rod at the rear of the muffler to the rubber mount on the vehicle. Repeat for the left side using muffler #942548-182.

3) Slip the right side tailpipe #16247 over the axle and into the right muffler outlet. Slide tailpipe hanger-rod into the stock rubber hanger at the rear of the vehicle. Install a 2 1/2" clamp and tighten enough to hold, but still allow for adjustment. Repeat on the left side using tailpipe #16246.

4) Adjust the position of the tailpipes for proper alignment and tighten all connections. Maintain a minimum of 1/2" clearance around all parts of the system; while keeping suspension travel and vibration in mind.

5) After all slip fit connections are secure, slide the provided 7/16” hanger keepers onto the ends of the hangers located at the rear of the mufflers and tailpipes up to the rubber mounts. This will hold the system securely in place.

6) For a cleaner appearance and more secure installation, we highly recommend welding all slipfit connections. If you live in a geographical area that has harsh winters or sees a great deal of precipitation, the use of temperature paint over the welded areas can help to prevent surface rust and premature corrosion.