How to Install a Ford Racing 5.0L Oil Pan Kit in you 1979-1995 5.0L Mustang

Installation Time

2 hours

Tools Required

- Torque Wrench 10 to 150 ft-lbs

- Hex Sockets- 3/8 twelve point, 3/ 8 hex, and 5/16 hex, 9/16 hex

- Black RTV Gasket Maker

Shop Parts in this Guide

Time Required: Approximately 1 hour and 15 minutes

Tools Required:

− Torque Wrench 10 to 150 ft-lbs (must be adjustable down to at least 10 ft-lbs)

− Hex Sockets- 3/8 twelve point, 3/ 8 hex, and 5/16 hex, 9/16 hex

− Black RTV Gasket Maker

Note: If you are using a high volume oil pump you will need to verify that the pan will fit without hitting the bolts on the oil pump because the high volume pumps tend to be a small amount taller than OE.

Testing Proper Fitment (prior to actual installation):

1. Prior to installing the oil pan permanently it is a good idea to double check that the main bolts are torqued to the correct specifications.

2. The bolt that is supplied must be torqued into the third main spot to 70 ft-lbs in three equal increments (Figure 1).

Figure 1

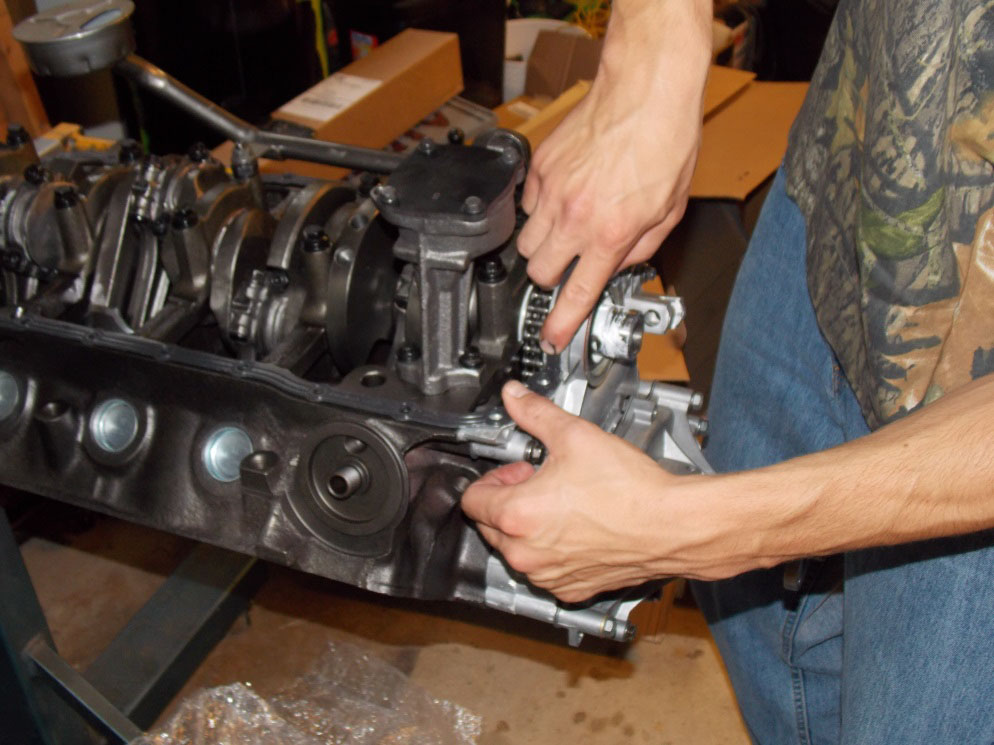

3. After verifying that your main bolts are torqued to the correct specifications and the oil pump has been installed, it is now time to install the oil pump pickup.

4. Start by placing two drops of either new engine oil or another engine friendly lubricant on the gasket (Figure 2). This will help keep the gasket in place while you are mating the pickup surface to the pump surface.

Figure 2

5. The next step is to prepare the oil pump pickup bolts that will be screwed into the oil pump. Put a small amount of anti-seize on the end of the threads. I used Permatex anti-seize but there are other companies that also produce the same compound (Figure 3).

6. It is important to not put bolts in without applying anti-seize prior to installation because an inaccurate torque may result. The oil pump bolts that I used are made by ARP and the part number is 254-1802.

Figure 3

7. Once the oil pump pickup gasket has been placed on the face of the pump where the pickup will go against, the next thing that you must do is torque the bolts that connect the pickup to the pump to 12 to 15 ft-lbs with the 3/8 12 point hex head(Figure 4).

Figure 4

8. Once the two oil pickup bolts have been installed and torqued down, you must take the 9/16 hex socket head and tighten the nut down so that the pickup is secured to the supplied bolt (Figure 5).

Figure 5

9. Prior to placing the oil pan on the block, it’s important to spray WD-40 into the inside of the pan and wipe it out to ensure that none of the manufacturing oils get on other internal engine parts (Figure 6).

Figure 6

10. Place the oil pan on the block to test fit it (Figure 7). Pay attention to whether or not the pan is clearing the pickup and the oil pump. If it is not clearing the pickup or the oil pump STOP! Serious damage will result to the pan or the pickup!

Figure 7

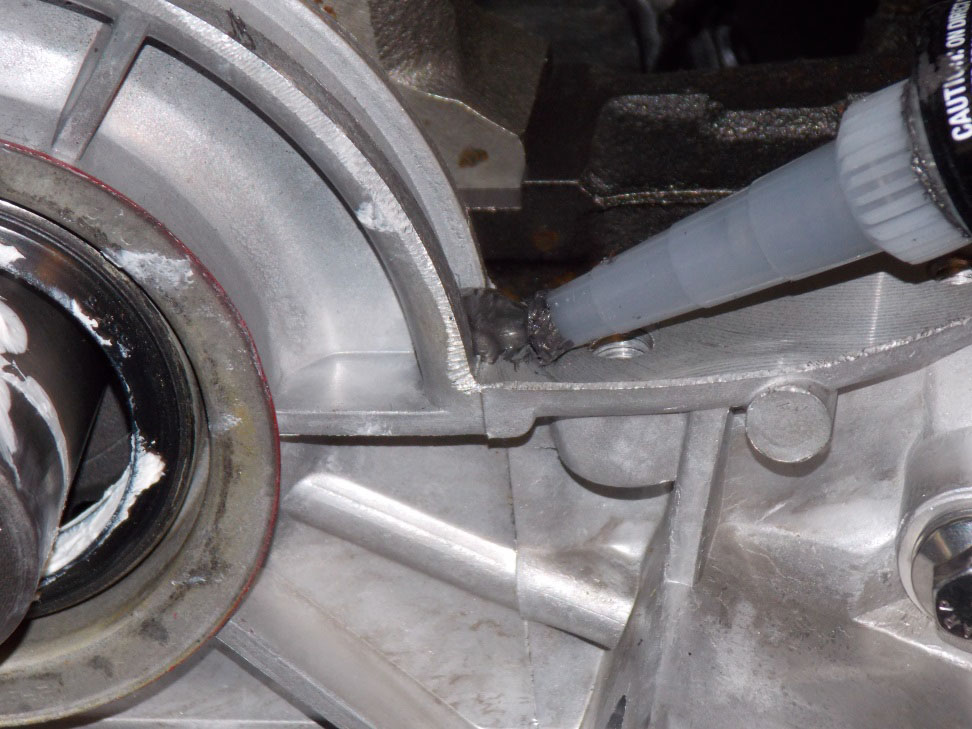

11. Once you have verified that the pan will fit without any problems, it is now time to install the oil pan gasket. First, squeeze the RTV into the corners of the timing cover and at the corners of the rear main cap (Figures 8 and 9).

Figure 8

Figure 9

12. Place the provided rubber gasket on the block following the outline of the block. Make sure to fit the circular portions of the gasket into the grooves on the timing cover and the rear main cap (Figure 10).

Figure 10

13. Place the pan over the gasket and begin putting anti-seize on the bolts from the oil pan bolt kit (Figures 11 & 12).

Figure 11

Figure 12

14. It is important to note that there are four bolts that are larger than the others. These larger bolts go in the holes directly to the left and right of the center of the timing cover and the rear main cap. The remaining smaller bolts fill in the other spots along the pans sides. Torque all of these bolts to 12-15 ft-lbs.

15. Once this is completed, the installation of the oil pickup, gasket, and pan is complete (Figure 13)

Figure 13

Installation Instructions Written By AmericanMuscle Customer Andrew Peters 8/20/2013