Guaranteed Free Delivery by 12/24! available on most items - Details

Talk to a Mustang Sales Tech

1-610-990-4562

M-F 8:30A-11P ET, Sat-Sun 8:30A-9P ET

How to Install Ford Racing Laser Etched Valve Covers on Your 2005-2010 Mustang GT and GT500

Installation Time

2 hours

Tools Required

- 1/4" ratchet

- 3/8" ratchet

- 8mm socket

- 10mm socket

- 7mm socket

- 1/4" & 3/8" extensions

- Plastic gasket scraper

- Ford Factory Service Manual (FSM) specifies:Motorcraft Metal Surface Prep (ZC-31)

- Motorcraft Silicone Gasket Remover (ZC-30)

- Motorcraft Silicone Gasket and Sealant (TA-30)

- Motorcraft Silicone Brake Caliper Grease and Dielectric Compound (XG-3-A)Rags and shop towels

- The FSM is useful, but is not required.

- An extra set of hands helps!

Shop Parts in this Guide

Installation

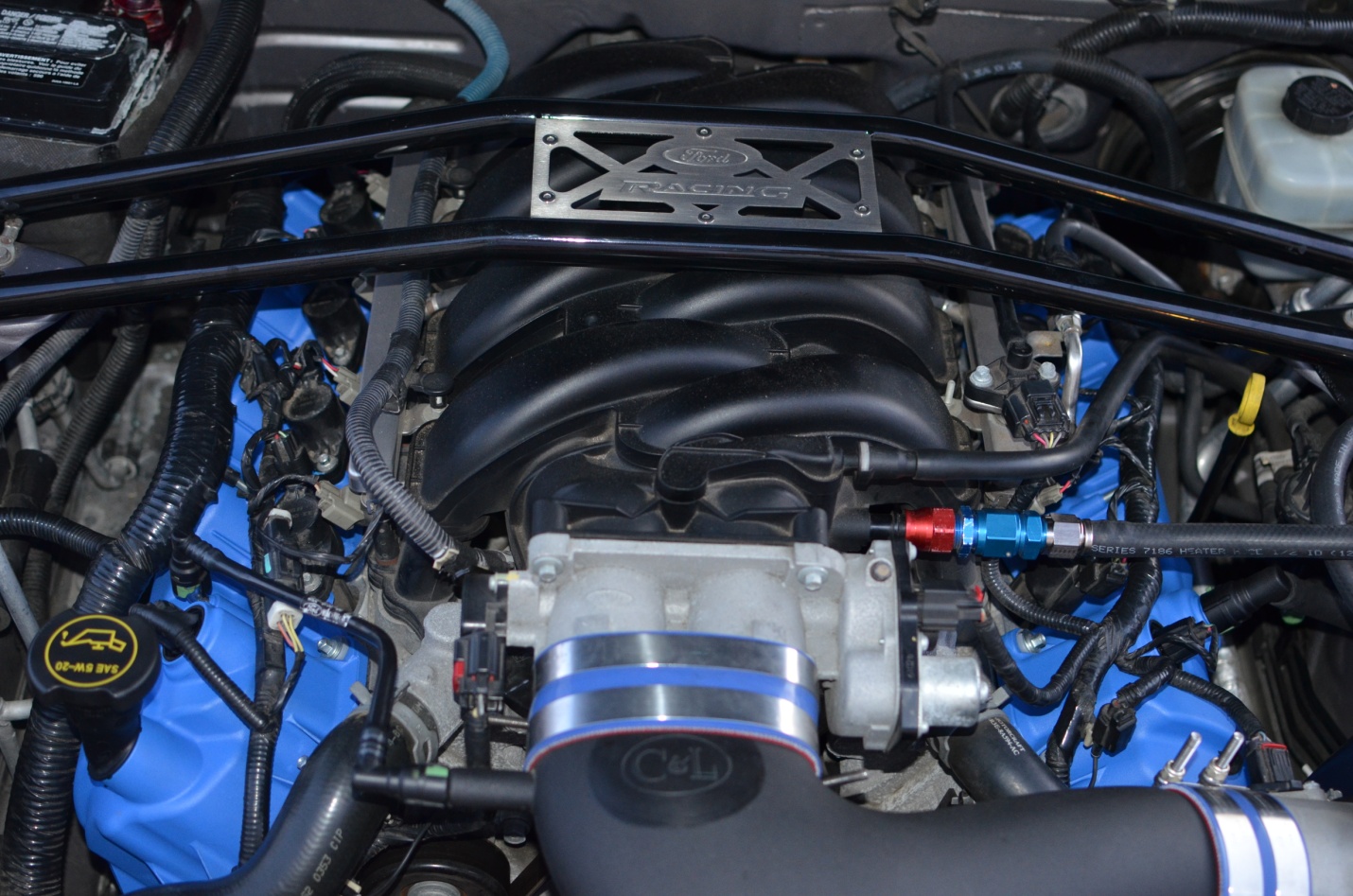

Figure 1- Before Picture

Preliminary steps

- Disconnect the battery

- Remover the strut tower brace (if installed)

Driver’s Side (LH)

*NOTE* Many of the pictures show the right hand side because they came out better. The Parts are identical Right to Left

- Remove the factory air intake or Cold Air Intake (CAI) - C&L Racer Intake pictured

- Disconnect the MAF sensor. (Figure 2)

- Disconnect the passenger side PCV hose.

- Disconnect air intake from throttle body.

- Disconnect air filter box (or CAI heat shield).

- Remove air intake.

Figure 2 - Removing the Cold Air Intake (or stock air intake) and MAF

- Remove the driver’s side PCV hose

- Remove the coil plugs – twist and pull

- Remove the screws attaching the coil plugs to the valve cover using the 7mm socket (Figure 3, and Figure 4)

- We completely disconnected them, labeled them, and set them aside (in order )

Figure 3 - Coil on Plug Bolts (Red), Electrical Connector (Yellow) and Fuel Injector Electrical Connector (Green)

Figure 4 - Remove the coil-on-plugs (RH side shown)

Figure 5 – Fuel Injector Electrical Connection

- Disconnect the Fuel Injector Electrical Connectors (Figure 3 and Figure 5)

- Remove the evaporative emissions (EVAP) line from the intake manifold

- Disconnect the LH variable camshaft timing (VCT) sensor (Figure 6)

Figure 6 - Remove the VCT Solenoid electrical connection

- Remove wiring harness retaining pins (2) from the covers (Figure 7)

- Remove the wiring harness retainers (2) from the studs (Figure 8)

Figure 7 - Retaining Clips, Pin Type

Figure 8 - Retaining Clip, Stud Style

- Remove the valve covers.

- It helped to loosen the oil dipstick tube, but it’s not necessary.

- Be careful to lift straight off until you clear the VCT solenoid.

- The bots (8mm socket) are captive in the grommets so you will not need to remove them from the valve covers.

- We used a few different length extensions and a u-joint to get to all of the bolts.

- Clean the gasket sealing surface.

- The Ford Factory Service Manual (FSM) specifies:

- Motorcraft Metal Surface Prep (ZC-31)

- Motorcreft Silicone Gasket Remover (ZC-30)

- We used a plastic scraper and some parts cleaner to remover the old RTV sealant and clean the sealing surface.

- Be careful not to scratch or gouge the surface.

- Be careful not to get the RTV material in the cylinder head. We used a rag and were careful to prevent material from falling into the cylinder head.

- The Ford Factory Service Manual (FSM) specifies:

- Apply a bead silicone gasket and sealant (Motorcraft TA-30) in the two locations (Figure 9 and Figure 10) where the front cover and cylinder head meet.

- We did a trial fitment check before putting the silicone down.

Figure 9 - Silicone Gasket and Sealant Location, Lower. (image from removal step before scraping old gasket clean)

Figure 10 - Silicone Gasket and Sealant Location, Upper

- Position the valve cover (shown in Figure 11) making sure that the wiring harness is clear and out of the way.

- Having an extra pair of hands helps here; after positioning the valve cover one person can lift while the other person applies the silicone. Otherwise apply the silicone and then carefully move the valve cover into position.

- Make sure you have the right extensions handy.

- Install the valve cover and tighten the bolts to 10 Nm (89 lb-in).

- With the wiring bundles pulled out of the way slide the valve cover into position.

- You will not be able to get a torque wrench on many of the bolts. Make sure you get a good feel for what 10Nm feels like one of the easily accessible bolts. (It’s not much).

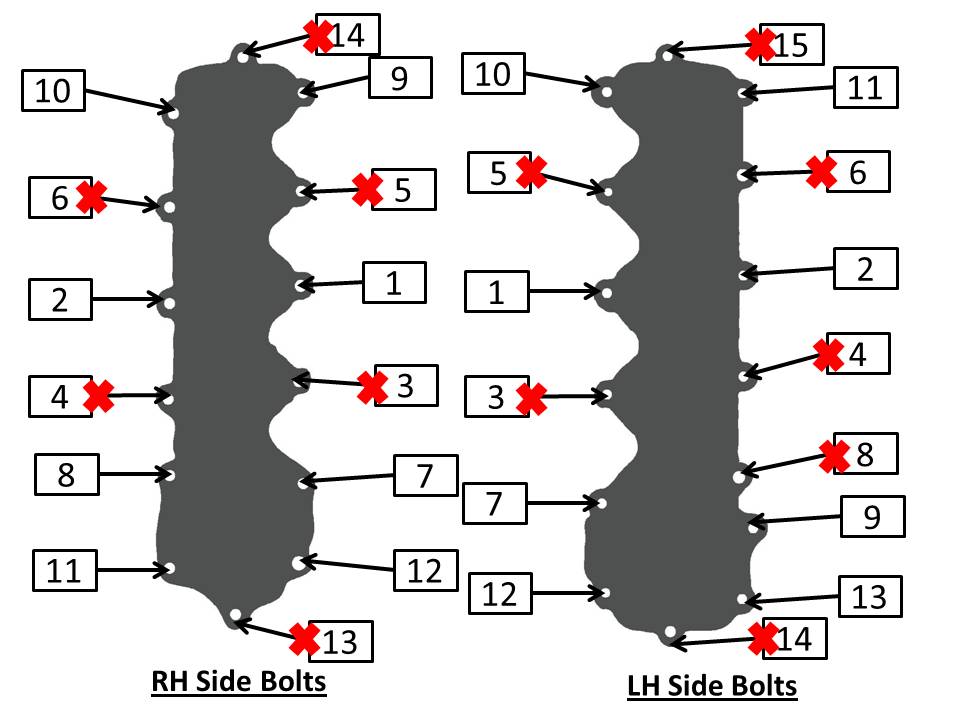

- Tighten in the sequence show in Figure 12.

- There are only 9 and 8 bolts on the left and right, respectively.

- Use the same sequence specified by the FSM by skipping the missing bolts.

Figure 11 - Installing the valve cover

Figure 12 - Tightening Sequence

- Attach the wiring harness retaining pins.

- Connect the VCT solenoid connector.

- Install the PCV tube.

- Install the EVAP tube.

- Install the coil-on-plugs.

- Apply Silicone Brake Caliper Grease and Dielectric Compound (Motorcraft XG-3-A).

- Install the coil-on-plug and tighten the bolt to 5 Nm.

RH Side Valve Cover Installation:

- The RH side is very similar to the LH Side.

- You will need to remove the oil fill tube and install it on the new cover. We did this before installing the cover, but I think you can do it after the install.

Finish the install:

- Reinstall Air intake box or CAI.

- Reinstall the strut tower brace (if applicable).

- Reconnect the battery.

- Take pictures and enjoy!

Figure 13 - The Final Result

Installation instructions provided by American Muscle customer Michael Iacchei 5.10.12