How to install a Rear Window Louvers 1979-1993 on your Mustang

Shop Parts in this Guide

Installation

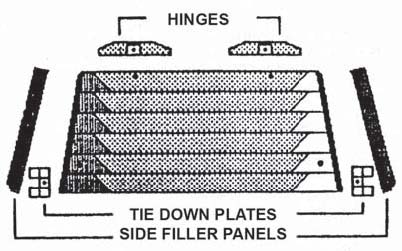

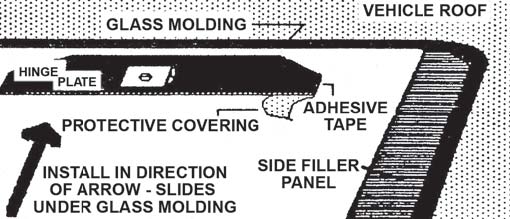

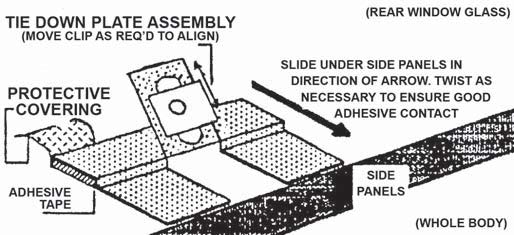

NOTE: Side filler panels must first be installed by sliding under glass molding on each side. Then the tie down plates slide underneath the side filler panels.

1. READ INSTRUCTIONS COMPLETELY BEFORE STARTING.

Refer to drawings often. Check hardware kit before starting to insure all pieces are included. Make sure you have the right part number. The louver number is stamped on the back of the slats. If you need to order additional parts, you can order directly from Willpak by calling 1-888-945-5725 or 905-827-0224. In order to reduce shipping costs to you, some of the louvers have been designed to separate into two halves. If you have a two piece louver, follow the next five steps to assemble your louver into one piece. If your louver was shipped in one piece move on to the preparation and installation steps.

2. TWO PIECE ASSEMBLY STEPS

1. Lay the louver upside down on a flat non-abrasive surface (i.e. a carpeted floor, the louver packing material or a piece of cardboard will do).

2. Start on one side of the louver and slip exposed slat of one half into the channel side piece of the other half and push the halves together.

3. Repeat the process with the opposite side of the louver making sure the center strip tongue and groove assembly slips together. NOTE: due to the geometry of some louvers, the lower piece may need to be bowed in order to slide the two halves together.

4. When the entire louver is in one piece, screw the two halves together at the center strip by using the Phillips head sheet metal screw provided. The holes in the tongue and center strip will not line up. This is intentionally done so that by tightening the screw the two halves will be forced tightly together. (Models for cars without rear window wipers have a strip of adhesive padding on the back of the center support strip. Peel the padding back slightly to expose the screw hole in the center strip tongue.)

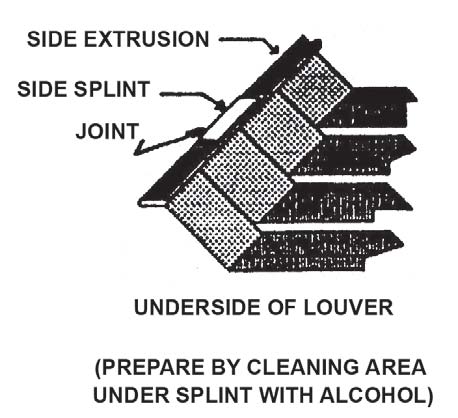

5. After assembling the louver and tightening the center screw, proceed to add the side splints. The purpose of the side splints is to provide additional support for your two-piece louver. Peel the backing from the ¾” wide adhesive on the side splints provided in the hardware kit. Be sure the louver side extrusion joint is tightly pressed together and the louver surface is clean (see the preparation steps on cleanliness etc.). The ide splint may now be placed on the underside of the louver as shown. Press the plate firmly in place and repeat the process on the other side. Now thoroughly read the installation instructions before you proceed.

3. CARS WITH REAR WINDOW WIPERS

(Non-Wiper Models – Skip to Preparation Steps)

Due to variations in location of factory installed rear window wipers, some wipers may touch the louver or louver hardware when parked or at the full extreme of operating travel. There are two ways to correcting this. This first is to re-index the wiper arm. Remove the wiper arm assembly where the wiper arm is connected to the motor shaft by lifting the locking tab and lift the arm off the shaft. Operate the wiper mechanism and turn to the “OFF” position. With the wiper turned off, push the arm assembly back on the motor shaft allowing 1/2” clearance to the louver. This will allow the wiper to cycle normally without hitting the louver.

The second method of correcting wiper hit is to purchase a wiper assembly approximately 2 inches shorter than the factory-supplied wiper assembly and install it in place of the original.

4. PREPARATION STEPS

NOTE: You will need the following items on hand to make a good installation:

1. Paper towels or a clean lint free rag to clean the window.

2. A bottle of rubbing alcohol to clean the window. Nothing else will clean the window without affecting the adhesive strength of the attaching hardware.

3. A soft lead pencil or wax crayon to mark the hardware positions.

4. Putty knife

Clean the glass with alcohol and paper toweling or clean rag, giving special care to ensure clean edges and corners. The glass must be above 60oF (warm to the touch) for the special adhesive to bond securely. If necessary, warm the glass with the rear window defogger or a hair dryer.

To achieve proper fit of all components, they must first be temporarily secured or “tacked” to the glass as outlined in the following installation steps.

After complete installation of the louver, avoid pressure spray car washes or extreme cold weather for the next 24 hours to allow the adhesive to bond properly.

5. INSTALLATION STEPS

Take the two side panels and trial fit each to the glass. The outer edges should slip under the window molding. Use a putty knife to assist in this procedure. Peel back a small section (1” or less) of the protective cover on the double sided tape along the straight edge. Use a crayon or soft pencil to mark the location of each side panel in its best fit location. Tack in place by pressing on the side panel where the protective cover has been removed from the tape.

In order to ease the installation of attaching hardware on cars with rubber window molding, lubricate the part of the plate that goes under the molding with a small amount of dish washing detergent.

Place the louver on the window with the leading edge of the top slat as close to the window molding as possible and centered side to side. Using a soft lead pencil, mark lightly on the molding the location of the two hinge holes at the top of the louver. Then on the side panels mark the location of the two tie down studs at the lower outside edges. When all four marks have been made on the molding and side panels take the louver off the window. (On cars without edge molding on the glass, use a crayon and mark the glass-itself).

Fold back a small section of the protective backing from the double-sided tape on both hinges, as shown. This will allow you to “tack” them in place during the trial fit. Using a putty knife lift the molding and slide the plate under starting with one corner. After the hinges are under the molding, slide them as necessary to align with the pencil mark made previously. Push the corner with the exposed tape against the glass to hold it in place. Repeat the process for the two tie downs making sure to slide the feet under the plastic side panels. In some instances it may be necessary to slightly bend the upright part of the tie down to more easily align it with the stud in the louver.

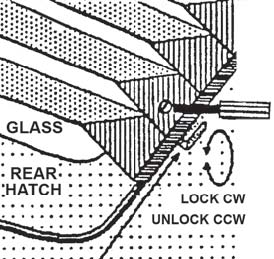

When all attaching hardware has been ‘tacked’ in place, re-set the louver on the car and fasten the hinges and 1/4 turn tie downs.

If any of the attaching hardware does not fasten to the respective mounting part of the louver, slide it into the proper position.

After the louver has been temporarily fastened to all four pieces of attaching hardware, remark the location of the hardware if necessary. This will help ensure position location for permanent mounting. Unfasten and remove the louver from the car leaving all attaching hardware still ‘tacked’ to the glass.

Without moving the hinges or tie downs, carefully remove the remainder of the protective backing from the double sided tape and press all parts firmly onto the glass. Check the taped areas from inside the vehicle. Look for air bubbles or signs of incomplete bonding and rework any areas by pressing firmly into place.

Peel the remainder of the protective covering from the tape or the side panels and press them into place using the crayon or pencil marks at a guide.

Mask off an area around the brackets. Apply a thin bead of clear or black silicone to all edges of the hardware mounting plates and “squeegee” in with a finger to ensure moisture cannot “undercut” the tape. Remove mask from rear window Bonding takes 24 hours to cure.

Do not install the louver during this time period. Do not wash car or drive in rain during this period.

Reinstall the louver. Loosely fasten the hinge screws. Then fasten 1/4-turn fasteners. Then tighten the hinge screws. Avoid pressure spray car washes and extreme cold weather for the next 24 hours to allow the adhesive to cure.