How to Install Maximum Motorsports Rear Lower Control Arms on your 1999-2004 Mustang

Installation Time

4 hours

Tools Required

- Jacks (yes, 2)

- Jack Stands (2 pair preferred)

- Lug Wrench

- Lug Nut Key

- Torque Wrench

- 1/4 Ratchet

- 1/2 Ratchet

- 1/2 Breaker Bar

- 1/2 3-Inch Extension

- 1/2 Wobble Socket

- Slip Joint Pliers

- Small Needle Nose Pliers

- Anti-Seize

- Thread Locker

- 1/2 Drive Sockets (15mm, 17mm, 18mm, 21mm)

- 1/4 Drive 8mm Socket

- Brake Cleaner

- Propane Torch*

- Grinder with 1/16 Inch Cut Off Wheels (yes, plural, I used 3 or 4)*

- Ice Pick or some other thin hard tool*

- Punch and Hammer*

- Ear Plugs*

- Safety Glasses*

Shop Parts in this Guide

Tools Required:

Jacks (yes, 2)

Jack Stands (2 pair preferred)

Lug Wrench

Lug Nut Key

Torque Wrench

¼ Ratchet

½ Ratchet

½ Breaker Bar

½ 3 in Extension

½ Wobble Socket

Slip Joint Pliers

Small Needle Nose Pliers

Anti-seize

Thread locker

½ drive sockets (15mm, 17mm, 18mm, 21mm)

¼ drive 8mm socket

Brake Cleaner

Possibly necessary

Propane torch

Grinder with 1/16 cut off wheels ( yes plural, I used 3 or 4)

Ice pick or some other thin hard tool

Punch and Hammer

Ear Plugs

Safety Glasses

1) Loosen Lug nuts on both rear wheels

2) Block front Wheels and lift rear of vehicle. Place jack stands to support car (not under axle or control arms). I used a small section of the front torque boxes just in ahead of the front bushing on the LCA.

3) Remove both rear wheels

4) Remove the sway bar by removing the 2 bolts on each side holding it to the LCAs. Support the middle of the sway bar and remove the rear bolts first (You will need to slide the abs wire out of the bracket to access the bolt). Remove the front sway bar bolts and remove the sway bar from the car.

5) Slightly preload the axle end of the control arm with the jack. On the axle end of the control arm use the 18mm and 21mm socket to remove the nut to the end of the bolt but leave the nut on. (I had already removed the spring which is why it is not being supported by a jack in the picture)

6) Try to remove the bolt by pushing against the nut. If this doesn’t move the bolt you may have too much or too little preload on the axle end of the control arm, try raising and lowering the jack to see if that makes any difference (having a friend on hand will make this easier).

7) If you get the bolt out skip forward to step 15. If the bolt still won’t budge it is likely seized to the anti-crush sleeve inside the bushing. This happened to me and here is how I removed the rear bolt.

8) Unbolt the rear shock and the quad shock (18mm, 15mm) to let the axle hang as far as it can.

9) Remove the spring. If you have lowering springs you should be able to pry them out with a little effort. If you have stock height springs you will probably need a spring compressor or some other method of safely removing the springs.

These next steps are potentially dangerous, be extremely careful and only attempt if you are confident you can perform these actions safely. Wear eye and ear protection where prudent.

10) Make sure you are aware of the brake lines, gas tank, any wires etc. that you don’t want to get too hot while you use the propane torch to burn out enough of the bushing so that your cut off wheel will have easy access to the bolt on the inside of the bracket. If you cut on the outside it won’t do any good.

11) Use the pick to frequently knock bits of burnt bushing out, it will be much quicker than waiting for it to fall out on its own. I spent about 15-20 minutes on each side burning enough of the bushing out.

12) Once you have enough of the bushing burned out, get the grinder and start cutting through the bolts. Cut about halfway through then rotate the bolt to get to the other half. Again be cautious of where the sparks are flying.

13) After the bolt is cut the control arm should fall out of the way. Now you can use a punch and hammer to knock the leftover bolt and head out of the brackets.

14) You will need M14 bolts and nuts and washers to replace the ones you cut, I used 90 or 100 mm long bolts. 9/16 is very close but the bind very easy as they are the slightest bit too big. M14 is the perfect size.

15) To remove the front bolt it is likely necessary to lower the exhaust. This process depends on your specific exhaust system and since each exhaust is different I don’t know what tools you will need for your specific application. For a stock system first unbolt the hanger bracket from behind the mufflers. This is much easier than fighting with the rubber hangers.

16) Place a jack stand under the muffler to hold the exhaust up while you remove the bracket holding the exhaust tip under the rear bumper.

17) Now remove the bolts holding the flanges together behind the x/h pipe. It may be stuck at the flange. If it is put a piece of wood on the front face of the muffler and hit it with a hammer to knock it loose.

18) Now Lift the exhaust off the jack stand and let it lay on the ground.

19) Remove the front LCA bolts by accessing the nuts and bolts in the holes/pockets in the picture below. (18mm and 21mm)

20) You may have to use a wrench or a deep socket on the nut. Once the nut is off pry/push the bolt out towards the center of the car.

Installation

21) Lube one of the outer bushings and press it into the control arm. Lube a middle bushing and press it into the control arm, followed by the other lubed outer bushing. They will be assembled inside the control arm in the order shown in the picture.

22) Use a lot of lube on the inside of the bushing, making sure to get it in all the grooves. I used my pinky or you could use a small screwdriver. This lube is very tacky, so use gloves or wash your hands after this step. Push the anti-crush sleeve into the middle of the bushing making sure it all sits flush to make installing the LCA possible.

23) Make sure to install the LCAs on the correct side of the car, they are labeled. Coat the portion of the control arm bolt that will be inside the anti-crush sleeve with anti-seize to make future removal much easier. Put the front end of the control arm into the front pocket and push the bolt through the bushing. Install the nut and snug, don’t tighten, the nut onto the bolt (if not using a nylock style nut apply thread locker to the nut). (18mm and 21mm)

24) I installed the nuts on the inner side of the car so if I have to use a hammer to remove them next time I will have room to swing a hammer to push the bolt towards the outside of the car.

25) Press the lower spring isolator onto the control arm spring perch. Place a jack under the rear control arm bushing. Place the spring in place with the upper isolator on top of the spring and the lower pig tail wrapped around the rear of the spring perch. Lift until the spring is held in place with slight pressure.

26) Attempt to lift the rear of the control arm into the axle bracket. It may not go right in. keep in mind all the ways you can maneuver the axle around. For example jacking under the dif cover will make the axle rotate, while jacking under the pinion dog bone will lift it straighter. Also side to side movement is easier while installing the first LCA.

27) When you get the rear bushing in place slide another bolt that has been anti-seized through the bushing and install the nut (thread locker) snugly. (18mm and 21mm)

28) Install the other side using the same steps. It should line up easier since everything should be pretty much in place with 3 of the 4 control arms installed.

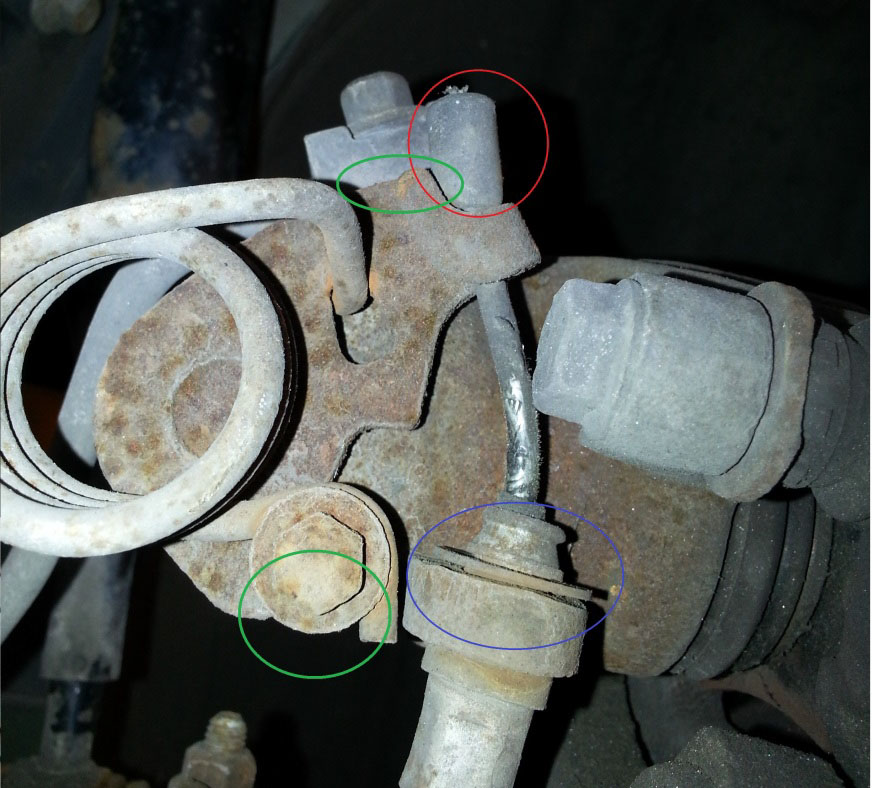

29) Remove the parking brake/abs bracket by first compressing the parking brake mechanism on the caliper using slip joint pliers (place jaws in green circles, be sure not to dislodge the spring) and pull the end of the parking brake cable out of its holder (red circle). Now remove the clip (blue circle) holding the parking brake cable to the caliper with small needle nose pliers.

30) Whatever you do, do not remove the parking brake spring. It will be easier to remove the spring than compressing it to remove the parking brake cable but it took me 2 hours to get it back in and even then it was only dumb luck that worked.

31) Slide the abs cable out of its bracket (red circle) and the parking brake cable out of the loop.

32) Use 8mm socket to remove the abs bracket from the parking brake bracket. Flip the parking brake bracket over and reinstall abs bracket on the other side. Bend the abs bracket towards what will be the rear of the car. (left-stock, right-modified)

33) Put the parking brake cable through the loop and reinstall the parking brake cable onto the caliper. Remember the round clip, and compress the spring to slide the cable end back in place.

34) Prepare the sway bar by removing the U-nuts from the sway bar (they just slide pry/slide off).

35) Start by installing the front bolt first (I used new bolts to go with the new nuts supplied) on both sides. Then install the rear bolts, through the parking brake/abs bracket. Reinstall the abs cable onto the abs bracket.

36) Torque all the nuts now. Front and rear control arm bolts get torqued to 111 ft/lbs and the sway bar bolts get 41 ft/lbs.

37) Reinstall the exhaust at the h/x pipe first, then support the mufflers on jack stands and install the exhaust tip bracket. Finally install the muffler hanger bracket. Keep the h/x pipe nuts loose until the rest of the brackets are tightened down, and then tighten the flange nuts and bolts.

38) Reinstall the lower shock bolts and the quad shocks onto their brackets and tighten the nuts down. (15mm and 18mm)

39) Clean the rotors off because they probably got a little dirty, plus it never hurts to clean the rotors.

40) Reinstall the wheels

41) Remove the jack stands and lower the car and torque all the lug nuts to 100 ft/lbs.

42) This is what the final assembly should look like, maybe without the anti-seize and ripped up label on yours.

Installation Instructions Written By AmericanMuscle Customer Stephen Vilcot 3.30.2013