How to Install Maximum Motorsports Severe Duty Oil Filter Relocation Kit (96-98 Cobra) on your Ford Mustang

Shop Parts in this Guide

Read all of the instructions before beginning work. Following the instructions in the proper sequence will ensure the best and easiest installation.

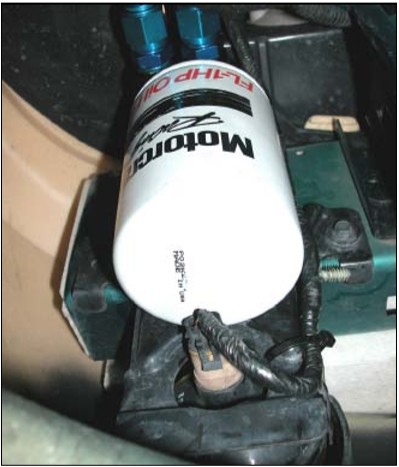

Maximum Mototrsports’ Modular Engine Oil Filter Relocation Kit moves the oil filter from the OE location to inside driver fender behind the bumper support. This kit is required for all Modular DOHC and SOHC engines with OE oil coolers when installing Maximum Motorsports’ tubular K-member. Installation of this kit mandates the use of a FL-1 series oil filter (or equivalent), thus allowing the Motorcraft FL-1HP Racing filter to be used on 4.6L Ford Modular engines.

1. Check the oil level and add oil, if necessary.

2. Jack up the front of the car and support securely on jackstands.

3. Remove the driver side wheel.

Filter Mount Installation

4. Remove the driver side driving light connector from the driving light. Position the connector up and out of the way.

5. Remove the outboard OE driving light bracket bolt.

6. Temporarily attach the Adapter Plate to the bumper support using the bolt removed at step 5 in its original position. Thread one of the provided self-tapping bolts at the unused hole in the bumper cover support behind the driving light bracket. The Adapter Plate is now used as a template for locating the position of a third mounting hole for the Adapter Plate.

7. Mark the location of the center hole of the Adapter Plate on the bumper support.

8. Remove the Adapter Plate.

9. Drill a ¼” hole at the location marked in step 7. The bumper support is made of a steel alloy that is difficult to drill. Use high-quality, sharp drill bits. Start by drilling a 1/8” pilot hole. Then enlarge using a 3/16“ drill bit, followed by a 1/4” drill bit. The use of multiple drill bit sizes simplifies this step greatly. When drilling, the front lip of the plastic fender liner may be pushed out of the way while drilling the hole to provide additional access for the drill.

10. Tighten one of the self-tapping bolts into the hole drilled at step 9 and then remove the bolt. This step forms threads in the hole.

11. Apply a light coat of motor oil to the O-ring of the two Straight Thread O-ring to -10AN fittings.

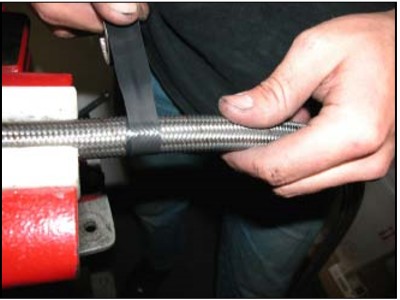

12. Place the Remote Filter Mount into a vise with “soft jaws” and install each of the two Straight Thread O-ring to -10AN fittings into the two ports of the filter adapter. Tighten the adapter nipples to 35 ft-lbs.

13. Attach the Adapter Plate to the Remote Filter Mount using the three supplied 5/16” bolts. Tighten the three bolts to 19 ft-lb.

14. Insert one of the self-tapping screws through the center hole in the Adapter Plate from the filter side of the Adapter Plate.

15. Place the thick 3/8” washer on the self-tapping bolt. The washer spaces the Adapter Plate away from the bumper support, providing clearance for the bolt heads installed in step 13.

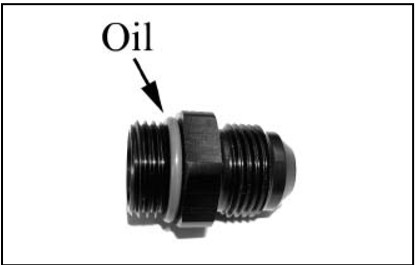

16. Attach the Adapter Plate to the bumper support by inserting the self-tapping bolt into the hole drilled at step 9. Leave the self-tapping bolt loose.

17. Place a thin 3/8” washer between the Adapter Plate and the driving light bracket at the hole where the OE driving light bracket bolt was removed. While holding the washer in place, insert the OE driving light bracket bolt through the Adapter Plate and loosely tighten back into its original hole.

18. Place a thin 3/8” washer between the Adapter Plate and the driving light bracket at the opposite corner of the Adapter Plate. While holding the washer in place, insert the remaining self-tapping bolt through the hole in the Adapter Plate and into the OEM-provided hole in the bumper support.

19. Tighten all three Adapter Plate bolts to 9 ft-lb.

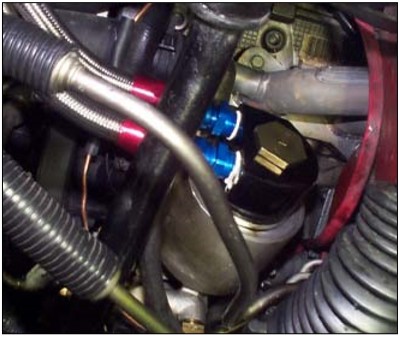

Engine Block Adapter Installation

20. Coat the tapered pipe threads of the two -10 AN to pipe fittings with the supplied Loctite Thread Sealant. Do not coat the leading thread. Place the Engine Block Adapter into a vise with “soft jaws” and install each of the two adapter nipples into one of the ports of the Engine Block Adapter. Tighten the adapter nipples. The tapered pipe threads form a wedge and the fittings do not bottom. Do not over-tighten, or damage will result.

21. Lube the Engine Block Adapter gasket with motor oil.

22. Place a drain pan under the oil filter and remove the oil filter. Be sure the filter gasket is removed with the filter.

23. Loosely attach the Engine Block Adapter at the OE filter location on the block. Rotate the Engine Block Adapter such that the adapter nipples face toward the front of the car.

Oil Line Fabrication And Installation.

24. Remove any tape and Inspect the ends of the supplied oil line hose. Choose the end of the hose that is in best condition. Install a 90-DEGREE fitting onto the this end of the hose. Start by disassembling the red socket from the blue nipple on one of the provided 90-DEGREE fittings. Install the red socket onto the end of the hose by twisting the socket COUNTERCLOCKWISE over the hose. Butt the end of the hose up to the base of the threads of the red socket.

25. Use a felt-tip pen to mark the hose at the base of the socket, so that you can tell if the hose is getting pushed out during the remaining steps of the fitting installation.

26. Use motor oil to lubricate the threads and the tip of the blue nipple that will be inserted into the hose. Use motor oil to lubricate the inside and cut end of the hose. Place the blue nipple in a vise. Hold the HOSE (not the red socket), and push the hose onto the blue nipple far enough to engage the threads of the red socket. Turn the HOSE to thread the red socket onto the blue nipple. Tighten as far as possible by hand.

27. When you can no longer tighten the fitting by hand, use appropriate size wrenches to tighten the fitting. Tighten the fitting until the red socket is within 1/16” from bottoming on the blue nipple. Do NOT use adjustable or oversize wrenches, or you will damage the fitting.

28. Make sure the mark made at the base of the socket at step 25 has not moved relative to the socket by more than 1/16”. If it has, remove the fitting and return to step 24.

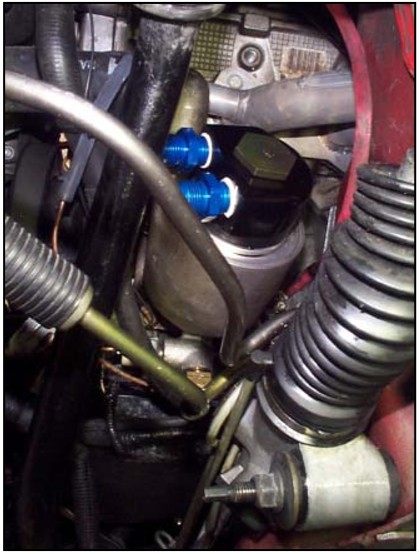

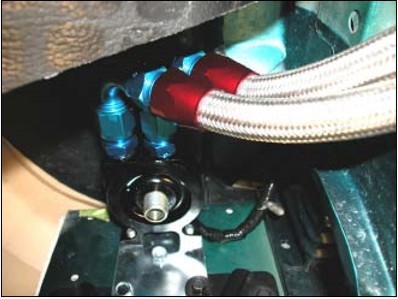

29. Hand tighten the attached 90-DEGREE fitting onto the adapter nipple of inboard port of the Remote Filter Mount (the adapter nipple closest to the radiator support).

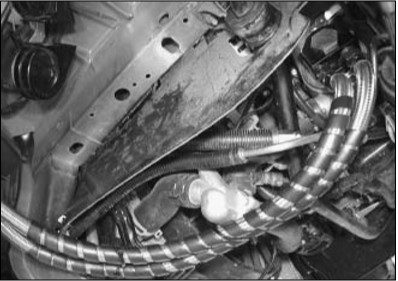

30. Route the hose under the frame rail, over the antisway bar and to the Engine Block Adapter. The specific routing should be based on your personal preference and vehicle configuration.

NOTE: It is important to understand that each one of the Remote Filter Mount ports must be connected to the correct port of the Engine Block Adapter. Specifically, the inboard port of the Filter Mount must be attached to the lower port of the Engine Block Adapter. The outboard port of the Filter Mount must be attached to the upper port of the Engine Block Adapter. This port orientation provides proper flow of oil through the filter.

31. Leaving a slight amount of slack for engine movement, hold the hose against the lower adapter nipple of the Engine Block Adapter and make a mark on the hose with a felt-tip pen.

32. Remove the hose from the Remote Filter Mount and remove the hose from the car.

33. Very tightly wrap tape around the hose centered over the mark made at step 31. Use a sharp 32 teeth per inch hacksaw and cut the hose through the center of the tape at the mark. Do not be tempted to use a hacksaw blade with fewer than 32 teeth per inch! Trim frayed ends of the hose with a sharp pair of diagonal cutters.

34. Remove the tape and repeat steps 24-28 for attaching a STRAIGHT fitting onto the cut end of the hose.

35. For reference, apply a piece of tape on this oil line. The tape will designate that this FIRST oil line should be attached between the inboard port of the Remote Filter Mount and the lower port of the Engine Block Adapter.

36. Repeat steps 24-35 to make a SECOND oil line to attach between the outboard port of the Remote Filter Mount and the upper port of the Engine Block Adapter.

37. Use a solvent such as brake cleaner to clean the assembled hose ends and fittings.

38. Attach the 90-DEGREE fitting of the SECOND oil line onto the outboard adapter nipple of the Remote Filter Mount and tighten to 15 ft-lb. If possible, use a crow foot socket and a small torque wrench. If you have trouble locating a crow foot socket, or your torque wrench is too big to fit in the required space, do your best to estimate 15 ft-lb.

39. Route the SECOND oil line under the frame rail, and over the anti-sway bar and clutch cable to the Engine Block Adapter. Do not attach the Second oil line to the Engine Block Adapter yet.

40. Attach the 90-DEGREE fitting of the FIRST oil line to the inboard adapter nipple of the Remote Filter Mount and tighten to 15 ft-lb.

41. Route the FIRST oil line under the frame rail, and over the anti-sway bar and clutch cable to the Engine Block Adapter.

42. Attach the STRAIGHT fitting of the SECOND oil line to the upper adapter nipple of the Engine Block Adapter and tighten to 15 ft-lb.

43. Attach the STRAIGHT fitting of the FIRST oil line to the lower adapter nipple of the Engine Block Adapter and tighten to 15 ft-lb.

44. Fine tune the orientation of the Engine Block Adapter in order to give the best oil line routing. Tighten the Engine Block Adapter to the engine.

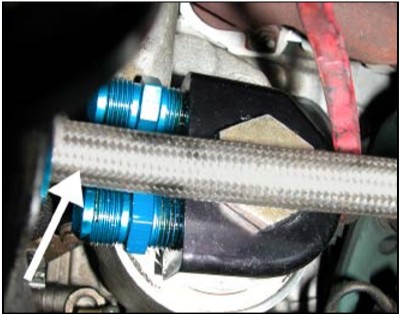

WARNING: Braided steel line is very abrasive. Normal engine and driving vibrations will cause it to wear through other items near it if it is not properly insulated.

45. Wrap each braided steel line separately with the supplied spiral wrap material as shown in the photo. DO NOT wrap them together, or the lines will wear through each other, with disastrous results.

46. Use the supplied zip ties to secure the oil lines as needed.

Finishing The Installation

47. Fill the provided oil filter with oil and hand tighten the filter on the Remote Filter Mount until the seal contacts the Remote Filter Mount. Tighten the oil filter 1/2 turn further.

48. Re-attach the driving light connector to the driving light.

49. Start the engine and examine all of the oil lines and oil line connections carefully to ensure that everything is tight and that there are no leaks. Turn off the engine after examining the oil lines and oil line connections.

50. Re-attach the driver side wheel. Torque the lug nuts to the appropriate wheel or vehicle manufacturer’s specification.

51. Lower the front of the car.

52. After letting the engine sit for an appropriate period of time, recheck the oil level. Add oil, if necessary.