How to Install a Moroso Air/Oil Separator on Your 2011-2012 Mustang GT

Shop Parts in this Guide

Installation

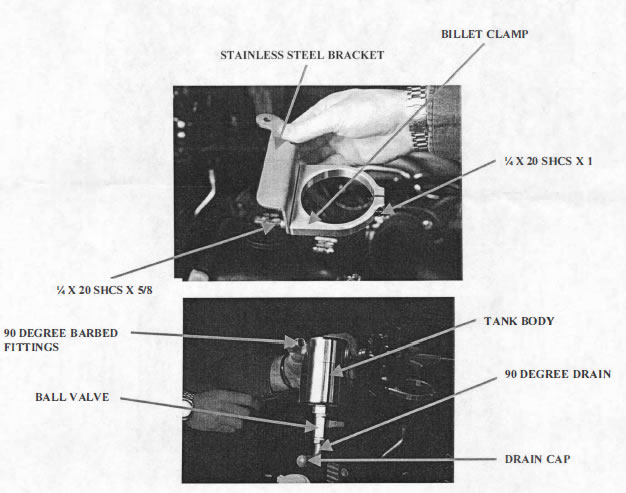

Parts List

- (1) TANK BODY

- (1) BILLET CLAMP

- (1) BALL VALVE

- (1) 90 DEGREE DRAIN

- (1) STAINLESS STEEL BRACKET

- (2) 90 DEGREE BARBED FITTINGS

- (1) LENGTH OF ½” TUBE

- (1) DRAIN CAP

- (2) ¼ X 20 SHCS X 5/8

- (1) ¼ X 20 SHCS X 1

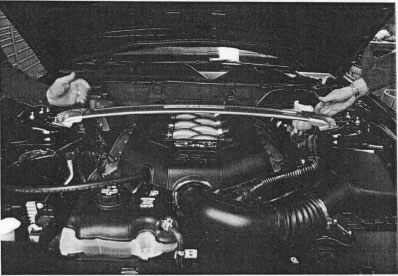

Step 1: Remove Strut Tower brace

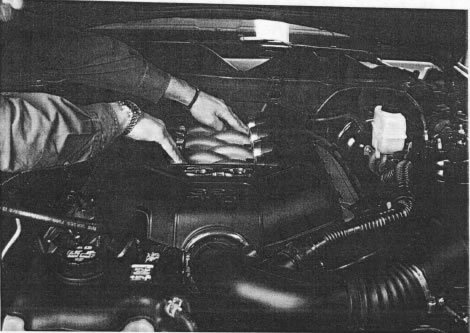

Step 2: Remove Intake Cover

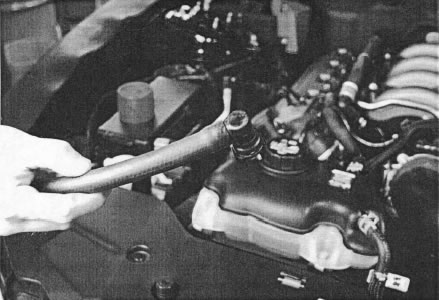

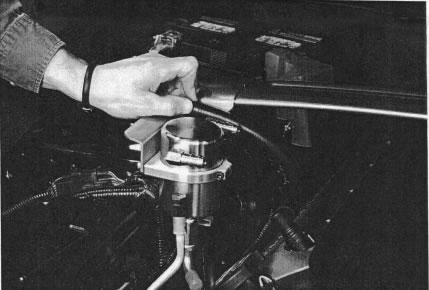

Step 3: Remove PCV tube from intake and valve cover

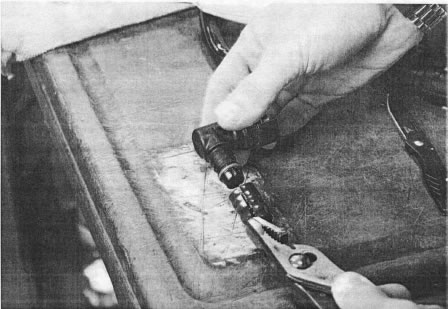

Step 4: Cut 90 degree fittings from PCV tube

Step 5: Cut / Remove remaining tube from 90 degree fittings

Step 6: Remove remaining tube from 90 degree fittings and set 90 degree fittings aside

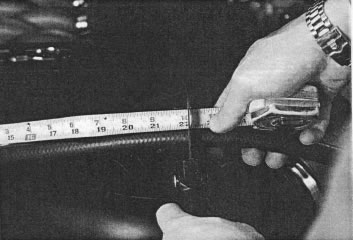

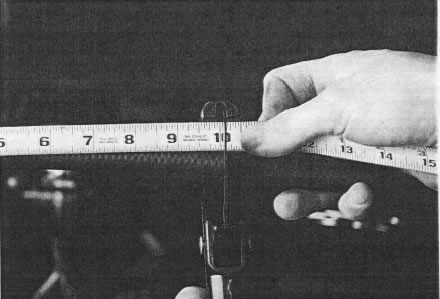

Step 7: Cut (1) pc of ½” hose 22” long

Step 8: Insert 90 degree fitting into one end of ½” hose

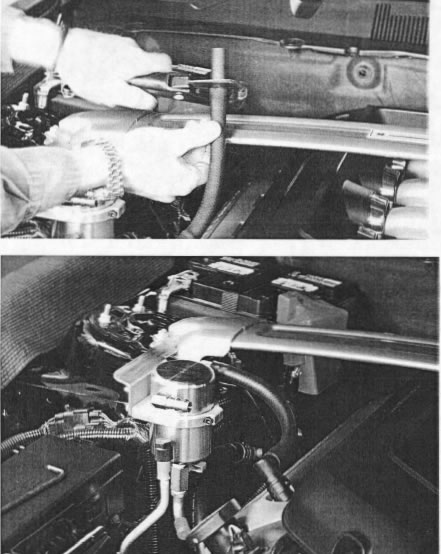

Step 9: Re-Install 90 degree fitting to intake

Step 10: Re-Install Intake cover

Step 11: Re-Install Strut Tower brace

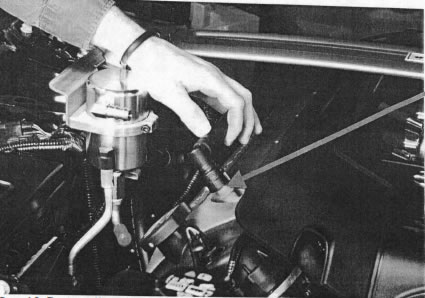

Step 12: Assemble Billet mounting bracket to stainless mount, note orientation of 1/4x20 SHCS

Step 13: Install Billet / Stainless mount to Strut Tower Brace

Step 14: Re-Install all mounting bolts

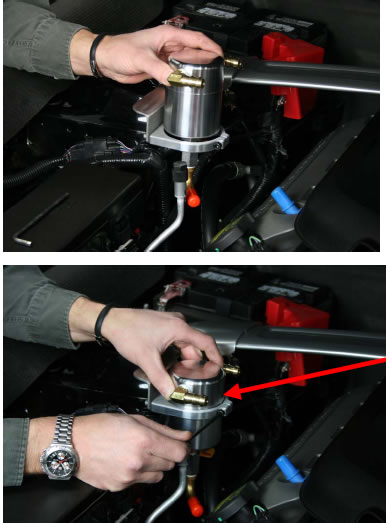

Step 15: Assemble Air Oil Separator as shown, apply Teflon tape to all fittings

Step 16: Insert Air Oil Separator into billet clamp, line up seam of Air Oil Separator with billet clamp

Step 17: Cut (1) pc of ½” hose 10” long

Step 18: Insert 90 degree fitting into one end of ½” hose

Step 19: Re-Install 90 degree fitting to valve cover

Step 20: Route ½” hose from valve cover to rear fitting of Air Oil Separator and mark for trim cut

Step 21: Trim ½” hose as needed and install to rear 90 degree push lock fitting

Step 22: Route ½” hose from intake to front fitting of Air Oil Separator and mark for trim cut

Step 23: Trim ½” hose as needed

Step 24: Install to front 90 degree push lock fitting

Install is Complete

Draining of Air Oil Separator is needed; this will depend on driving conditions (i.e.) normal day to day driving check every 1,000 miles until a baseline is established. A good baseline is to drain the Air Oil Separator when it is about HALF full. This will vary with temperatures (cold winters vs. hot summers). For track usage Air Oil Separator will need to be drained after every outing.

There are several different methods to draining Air Oil Separator. The first and simplest method is to place a cup or MOROSO part # 65805 under drain elbow and open ball valve, once draining is complete close ball valve. The second method is to run a length of ½” hose from elbow to under carriage of vehicle and place drain pan under vehicle at this time open ball valve, when draining is complete close ball valve. This hose may also be permanently installed for future draining.