Many people choose to install motor mounts when they are installing long tube headers. Because the stock motor mounts are typically removed for extra room during a header install, installing upgraded mounts with long tube headers can save you time and money. Upgraded mounts reduce the chances that your headers will rub on the frame of your Mustang, something that generally happens with lower quality headers. If your headers contact your Mustangs frame, engine vibrations will be passed into the chassis, causing unpleasant noise, vibration, and harshness. Frame contact can also trigger false knock, causing your PCM to pull timing, reducing the output of your engine.

Replacing motor mounts can be either a great idea or a downgrade. If the owner is after performance, poly mounts are the way to go. The stronger connection, consistent firmness, and better handling qualities can be greatly improved with poly mounts. However, if the Mustang is primarily for cruising the streets or just being comfortable, rubber mounts (even the stock ones) can perform that function well. Stock ones will feel smoother while poly mounts will feel more connected to the car while improving handling and increasing vibration. In the end, the choice is up to the driver, performance based or comfort based.

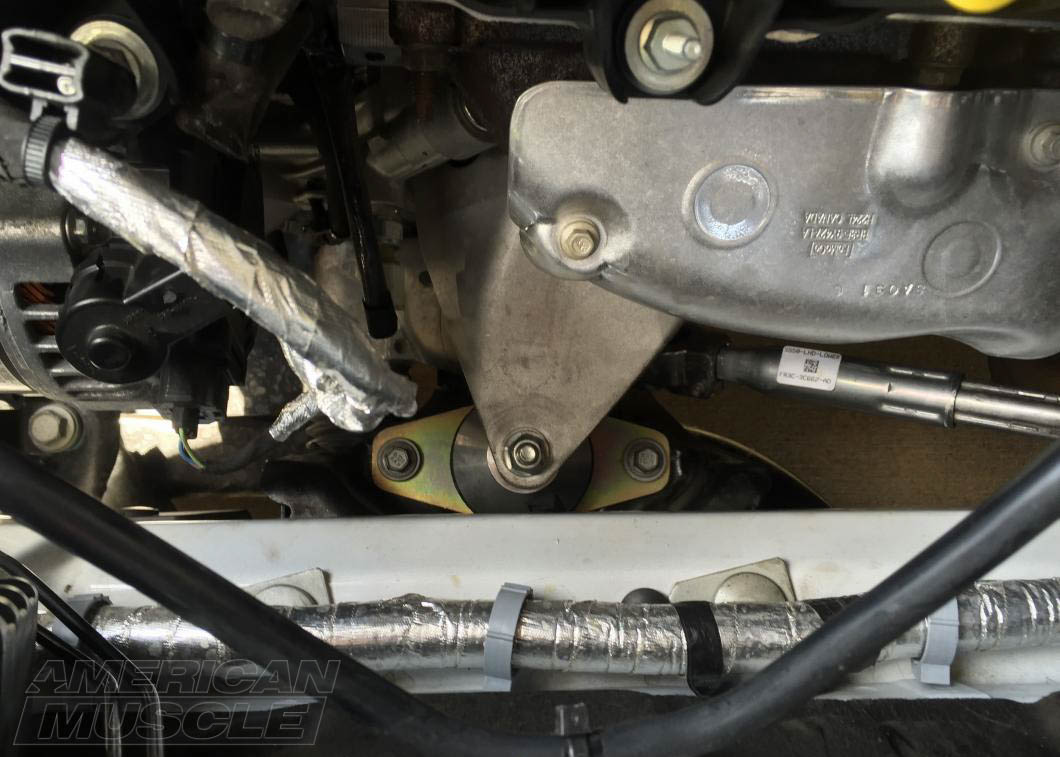

Lowered engine mounts are also required on the S550 (2015-current) Mustangs when installing upgraded intake manifolds like the Cobra Jet or Boss 302 intakes. Due to the tight clearance between the hood and engine, these taller intake manifolds either require a dropped engine mount, cut hood supports, or both. Dropping a set of lowered mounts in your Mustang will make it less likely that you’ll have to break out the cut off wheel when installing your new intake manifold.