How to Install a Oracle Halo Headlight Conversion Kit on your 2010-2012 Mustang

Installation Time

3 hours

Tools Required

- Small flathead screwdriver

- Large flathead screwdriver

- Ratchet

- 7 mm, 8mm, and 10mm socket

- Oven

- Heat Gun

- 2 2x4 12" long (other will work, see step 18)

- Caulking gun

- Exterior grade 100% black silicone caulk

- Super glue (optional)

- Heavy gloves

- Latex gloves

- In-line splice connectors (16-22 gauge)

- Male and Female Electrical connectors (18 gauge)

- Electrical tape

- Wire Stripper and Crimper

- Multimeter

- Pliers.

Shop Parts in this Guide

Installation

1. Remove the radiator cover retainers using a small screwdriver.

2. Remove the radiator cover.

3. Remove the 4 splash shield screws (2 each side) with the 7mm socket.

4. Remove the (4) 7mm bolts from the air dam in the front.

5. Remove the (5) 7mm bolts from the air dam under the car.

6. Remove the air dam.

7. Unplug the side marker lights. If equipped unplug the fog lights. Removing the bulb from the housing is another option.

8. Remove or unplug the ambient air temperature sensor in the front valence.

9. Bend the splash shield so that it is on the opposite side of the bumper cover.

10. Place one hand on the bumper cover in front of the light. Place the other on the back face of the bump cover by the splash shield. With that hand pull towards the front of the car until the cover pops off. Rep for the other side.

11. Remove the two 8mm bolts from the top of the grill, lift the cover off the tabs beside the bolts and rem the bumper cover.

12. Set the bumper cover aside. Take care to not damage the paint.

13. Remove the parking light and headlight bulbs.

14. Use the 10mm socket to remove the (2) lower bolts holding the headlamp assembly in for each side.

15. While supporting the headlamp assembly, remove the upper bolt and retaining tab.

16. Remove the headlamp assemblies.

17. Pre-heat the oven to 225-260 degrees Fahrenheit.

18. Place the 2x4 or other thick wood pieces into the oven for the headlamp assembly to sit on. NOTE: It is advised to only do one headlamp assembly at a time. Place the headlamp in the oven on top of the wo Set a timer for 10 minutes.

19. When the timer goes off remove the headlamp assembly using heavy gloves or other suitable heat insu The assembly will be hot and caution when working with it should be used. Do not turn off the oven.

20. Starting at the bottom, use the large flathead screwdriver to pry off the headlight cover. Continue arou cover, undoing the tabs as you go. It may be necessary to put the light back in the oven for another 10 minutes to reheat the sealant.

NOTE: Slight deformation of the cover will occur. If you do not hear or see the sealant yielding, try a different location or a higher temperature to prevent excessive damage to the headlamp covers.

21. Turn the oven off.

22. Remove the inner cover assembly using latex gloves. These should be worn while working with the inte the headlamp assembly to prevent contamination and fingerprints. If it is stuck, use the heat gun locally the retaining tabs. A screwdriver can be used to pry next to the tabs.

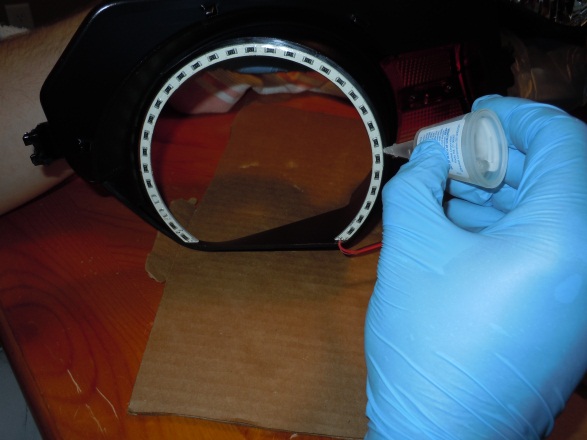

23. Remove the Oracle Halo unit from its wrapping. Test the LEDs using a 12 V power source. If faulty conta American Muscle or the manufacturer. Line up the ring with the back edge of the cover.

24. Once satisfied with the fit, remove the backing from the adhesive strip. Carefully apply the strip to the i cover. Press gently in a circular fashion on the strip to ensure proper seating. The side surface of the rin seat against the inner cover.

25. If there are gaps, push it to one side or the other. Use super glue on the side that is fixed. Allow the glu dry, then apply glue to the gap and press the ring to the housing, bracing the glued side to prevent it fro separating.

Optional – use black electrical tape to cover the gap from the back of the cover.

26. If the tabs on the headlight housing were bent, use the heat gun to soften the plastic and shape them b into position.

27. Clean any particulate from the inner cover and reflectors.

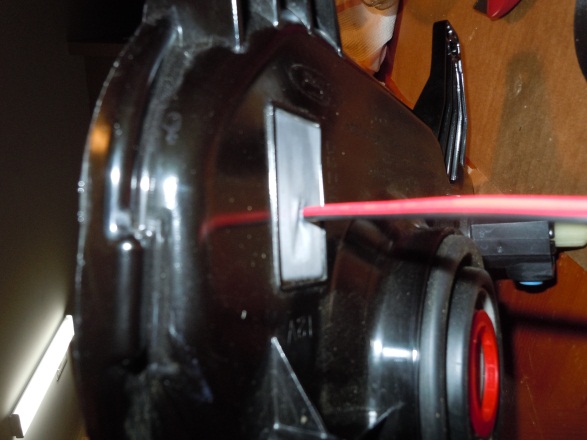

28. Use a small screwdriver to puncture the foam seal at the upper inner corner of the headlamp assembly

29. Insert the inner cover back into the housing. Route the wiring through the hole in the seal. Route the w behind the deflector and pull the slack out the back of the housing.

30. Remove any sealant from the headlamp cover with a screwdriver and the heat gun.

31. Test fit the headlight cover. Remove additional glue as necessary with the heat gun. Check that the tabs reengage, use the heat gun to reshape them as necessary.

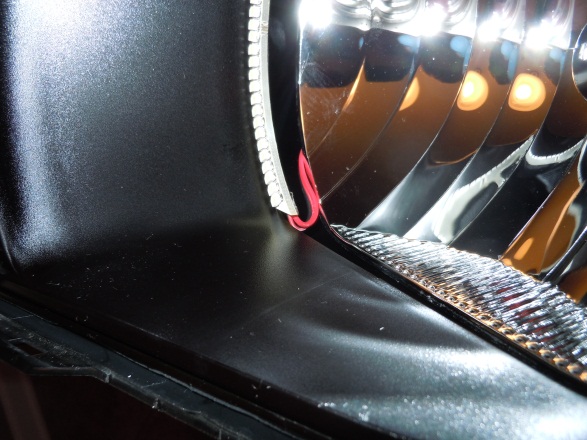

32. Once satisfied apply a small bead of black silicone around the housing to reseal it.

33. Carefully place the headlight cover back onto the housing. Make sure to redo the tabs. Allow the silicon set.

34. Repeat steps 17 through 33 for the other headlamp assembly.

35. At this point the lights can be wired into 5 locations: the headlights, fog lights, parking lights, or into an independent circuit. Depending on the lighting scheme desired, the wiring will vary. The instructions th follow are for the parking lights. To change options, consult an appropriate wiring diagram of your car, available from your Ford dealer.

36. Place the headlamp assemblies on the floor.

37. Isolate the parking lamp plug.

38. Use a knife, scissors, or a pair of snips to remove a portion of the wire routing.

39. Pull a little of the purple/white wire out of the routing. Use a knife to strip the insulation off approxima 1/16th of the wire.

40. Cut 6-8” of the Halo Ring lead wires off. Strip both ends (1/4”).

41. Take one of the in-line splices and put it around the purple white wire, centering the metal tab on the b portion of the wire.

42. Fold the ¼” of stripped red wire over the insulation.

43. Insert it into the splice and close the blue cover. It may be necessary to use a pair of pliers to close the c

44. Using the multimeter, check for continuity on the other end of the red wire and the purple/white wire using the terminal on the side marker light. If there isn’t continuity, redo the connection and check aga

45. Repeat steps 38 through 44 for the black/yellow wire, connecting the black wire to it.

46. Take one male and one female crimp plug and attach it to the free ends of the lead wires.

47. Strip the wires coming from the light assembly and attach corresponding crimp plugs to the wires.

48. Connect the plugs.

49. Turn on the parking lamp switch to check the electrical connection. If the lamp does not turn on, turn o switch and proceed to check your crimps for continuity with the wire. If the connections are sound, try switch again until the light turns on.

50. Wrap the plugs in electrical tape to seal the connection and prevent undesired disconnection. Do the sa for the in-line splices, sealing up the cut away portion of the corrugated routing as well.

51. Fold up the wires and use electrical tape to tie the bundle together. Install the headlight with the three 10mm bolts and tuck the wires securely out of the way. Don’t forget the pop-out tab.

52. Repeat steps 38 through 51 for the other light.

53. Place the bumper cover on the car. Connect the grill tabs and the two bolts.

54. Plug in the fog lights.

55. Tuck the splash guard behind the bumper cover on both sides.

56. Align the tabs at the top of the bumper cover.

57. Push the cover back into place on both sides.

58. Screw in the 4 splash guard to bumper cover bolts.

59. Reconnect the side marker lights.

60. Reconnect/install the ambient air temperature sensor.

61. Reverse steps 1 through 6 to install the lower air dam.

62. Done. Clean up the workspace and enjoy.

Installation Instructions written by AmericanMuscle customer Clint Lowe 5.31.12