Best Sellers

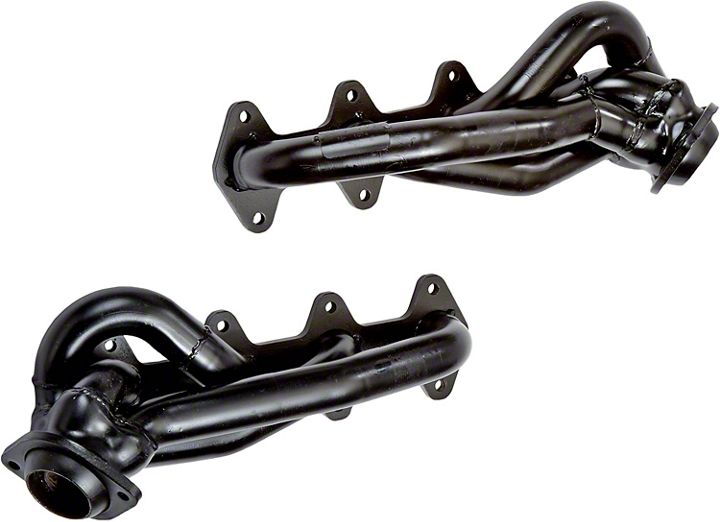

How to Install PaceSetter Black Shorty Headers on Your 2005-2010 Mustang GT

Shop Parts in this Guide

NOTE: Before beginning installation, be sure that vehicle is firmly supported by jack stands or ramps of sufficient load capacity for the weight of the vehicle. NEVER go under a vehicle which is supported only by its service jack.

INSTALLATION PROCEDURE:

1. Disconnect battery. Raise vehicle and support with jack stands or ramps of sufficient load capacity for the vehicle.

2. Disconnect all four O2 sensor connectors and remove H-pipe. Remove starter.

Unbolt steering coupler at steering rack. Remove left side steering rack mounting bolt and loosen right mounting bolt. Pry rack forward to disengage steering shaft from steering rack. Do not allow steering wheel/shaft to turn while disengaged.

3. Raise engine and remove motor mount brackets. Support engine in this position.

4. Remove exhaust manifolds. Remove exhaust manifold studs. Remove O2 sensor from left manifold and install into left side header.

5. Remove dipstick and dipstick tube. Remove chassis stiffener bar.

6. Clean gasket surfaces on cylinder heads. Apply a high temperature gasket sealer such as Permatex

Ultra-Copper on gaskets supplied with kit. Start left side lower rear header bolt through gasket and into head. Leave about ½" sticking out to slide header flange over. Install new headers with new bolts supplied in kit.

7. Torque header bolts from center out in stages. Final torque should be 18 ft.lbs.

8. Re-install dipstick tube. Install the ½" bushing between the dipstick tube bracket and cylinder head so that the dipstick tube will clear the header flange.

9. Reinstall motor mount brackets.

10. Guide the steering coupler onto the steering rack post while prying the rack back into place. Reinstall the left side mounting bolt and torque both mounting bolts. Reinstall and torque the steering coupler bolt.

11. Reinstall starter. Reinstall chassis stiffener.

12. Reinstall the H-Pipe and reconnect all O2 sensors.

13. Remove jack stands and lower vehicle. Re-connect battery and start engine.

Check for exhaust leaks, rattles, clearance problems. Correct if necessary.

NOTE: There may be some lubricant left in the tubes from the mandrel bending process. You may smell this lubricant burning off for the first few days of using your new headers. This is normal and will cause no harm and will disappear. After a few days of operation, check all fasteners and clamps. Retorque as necessary.