Talk to a Mustang Sales Tech

1-877-887-1105

M-F 8:30A-11P, Sat-Sun 8:30A-9P

Top Sellers in Mustang

How to Install a Snow Performance 2.5 Gallon Reservoir on your Mustang

Shop Parts in this Guide

Installation

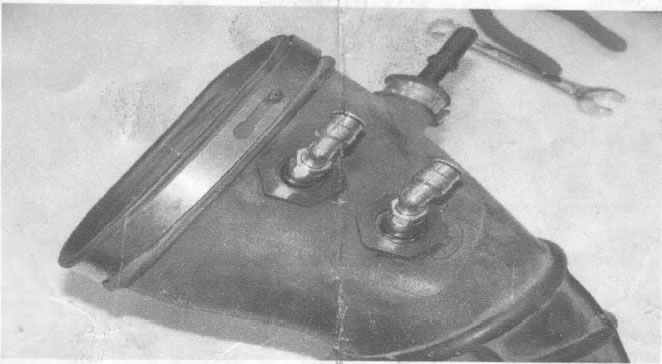

Dual Nozzle Upgrade #40040

This upgrade package provides the necessary fittings to run two nozzles simultaneously. This is ideal in applications that have dual throttle bodies or require large volumes of water-methanol for cooling, power, and octane.

Installation

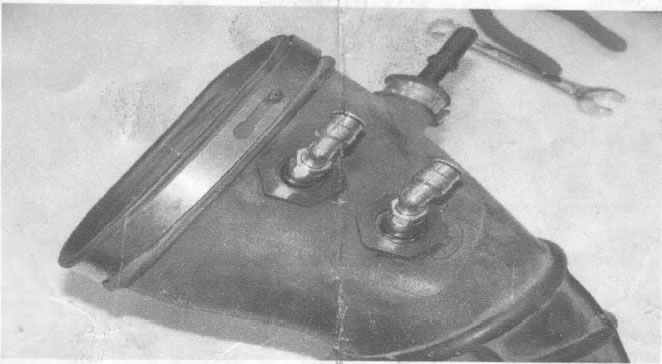

Dual Nozzle Upgrade #40040

This upgrade package provides the necessary fittings to run two nozzles simultaneously. This is ideal in applications that have dual throttle bodies or require large volumes of water-methanol for cooling, power, and octane.

- Mark the desired nozzle mounting points. ddeal locations are immediately before the throttle body on a gasoline engine or immediately before the intake manifold on a diesel engine. DO NOT inject before a centrifugal supercharger or a turbocharger, as compressor blade damage can result (many compressor wheels spin at 120,000 RPM and are quite delicate . In'ection before a positive dis lacement supercharger is ideal and helps to improve efficiency and cooling. In applications using a spacer plate #40050), note that there are two available ports on the plate. Either or both can be used. On circular pipes, the nozzles can be mounted in whatever direction is convenient. The nozzles can also be mounted next to each other or opposing each other, or at totally different points on the pipe.

- Remove the parts that the nozzles will be mounted on from the engine bay. Typical installations are into the tubing before the manifold or throttle body.

- Drill and tap (11/32 pre-drill, 1/8" - 27 NPT tap) in the desired locations. Be sure to clean out all metal shavings when you are finistred.

- Re-install the parts into the engine bay.

- Using a small amount of GOOP® sealant on the threads of the nozzles, screw the nozzles into the 90 degree nozzle holders. The mesh filter screen goes inside the nozzle holder. A half turn past finger tight is sufficient to seal the nozzle into the fitting.

- Using a small amount of GOOP® sealant on the external threads of the nozzle, screw the nozzles into the tapped holes. Again, a half turn past finger tight is usually sufficient for good sealing even in high boost applications.

- Determine a good location for the T fitting that will not cause any sharp bends or kinks in the tubing. Measure and cut tubing with a sharp utility knife to ensure a square clean cut. Install into the quick connects on the nozzle holders and T.

- Connect the remaining outlet of the 'T' to the main feed tube from the pump or solenoid. Use zip ties to secure loose tubing away from hot or moving engine components.

- Mark the desired nozzle mounting points. ddeal locations are immediately before the throttle body on a gasoline engine or immediately before the intake manifold on a diesel engine. DO NOT inject before a centrifugal supercharger or a turbocharger, as compressor blade damage can result (many compressor wheels spin at 120,000 RPM and are quite delicate . In'ection before a positive dis lacement supercharger is ideal and helps to improve efficiency and cooling. In applications using a spacer plate #40050), note that there are two available ports on the plate. Either or both can be used. On circular pipes, the nozzles can be mounted in whatever direction is convenient. The nozzles can also be mounted next to each other or opposing each other, or at totally different points on the pipe.

- Remove the parts that the nozzles will be mounted on from the engine bay. Typical installations are into the tubing before the manifold or throttle body.

- Drill and tap (11/32 pre-drill, 1/8" - 27 NPT tap) in the desired locations. Be sure to clean out all metal shavings when you are finistred.

- Re-install the parts into the engine bay.

- Using a small amount of GOOP® sealant on the threads of the nozzles, screw the nozzles into the 90 degree nozzle holders. The mesh filter screen goes inside the nozzle holder. A half turn past finger tight is sufficient to seal the nozzle into the fitting.

- Using a small amount of GOOP® sealant on the external threads of the nozzle, screw the nozzles into the tapped holes. Again, a half turn past finger tight is usually sufficient for good sealing even in high boost applications.

- Determine a good location for the T fitting that will not cause any sharp bends or kinks in the tubing. Measure and cut tubing with a sharp utility knife to ensure a square clean cut. Install into the quick connects on the nozzle holders and T.

- Connect the remaining outlet of the 'T' to the main feed tube from the pump or solenoid. Use zip ties to secure loose tubing away from hot or moving engine components.