How to Install Stifflers Driveshaft Safety Loop on your Mustang

Shop Parts in this Guide

Driveshaft Safety Loop

(DSL-M02)

Engineered to exceed NHRA regulations, this one of a kind driveshaft safety loop (DSL) will save you and your investment from the destructive effects of a broken driveshaft. Quick and easy bolt-in application requires no drilling or welding and weights almost 2 lbs. less than most popular styles! Comes complete with all mounting hardware. Works with a variety of automatic and manual transmissions (see below) and does not interfere with most aftermarket exhaust. Launch hard with confidence!

(Please read all instructions prior to beginning installation. Contact your dealer with any questions.)

Kit Includes:

1 DSL base plate

1 DSL loop

4 3/8-16 x 1 Hex Head Bolts

4 3/8-16 Pinch Nuts

4 3/8 SAE Flat Washers

2 1/2-13X1.5 Hex Head Bolts

2 ½ SAE Flat Washers

Installation:

1. Raise vehicle to allow access for installation; support with jackstands.

2. Support transmission with floor jack. Do not block access to cross-member mount or support on transmission pan.

3. Remove the two bolts attaching transmission to the transmission mount; they will not be reused.

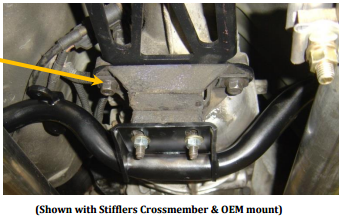

4. Install DSL base plate between the transmission and transmission mount; loosely secure using supplied ½” bolts and washers. (See Picture)

5. Confirm DSL base plate has equal clearance on each side around driveshaft and tighten ½” bolts (“B”).

6. Position DSL loop over mounting tabs on base plate. Confirm which set of mount holes are best for your application (Recommended setting is

bottom hole of loop to bottom hole on base plate.). Insert four 3/8” bolts from the outside and fasten tight with supplied washers and nuts.

[Note: When installing loop, it may be helpful to bring from the rear forward, following the driveshaft.]

7. Confirm adequate clearance (1/4”min.) between DSL and driveshaft assembly, adjust if necessary.

8. Remove floor jack and jackstands and lower car.

A Word about Pinion Angle

When the DSL is installed with the factory crossmember and transmission mount, the rear of the transmission is raised by the thickness of the DSL (1/4”). Doing this causes a change in the driveline angle which may induce driveline vibration, reduce traction under acceleration or cause unwanted stress in the driveline.

Therefore, to ensure optimum performance it is recommended to correct for the pinion angle change.

This can be easily accomplished in one of several ways:

- Use a Stifflers Crossmember (On ‘79~’98 Mustangs and Fox bodies)

[See Crossmember Install Instructions online for details]

- Maintain stock crossmember and replace the OEM mount with an Energy Suspension mount (P/N: 4.1104). This mount is ¼” shorter than OEM and will account for thickness of DSL. (On ‘79~’98 Mustangs and Fox bodies)

- If equipped, re-set pinion angle using adjustable rear control arms.