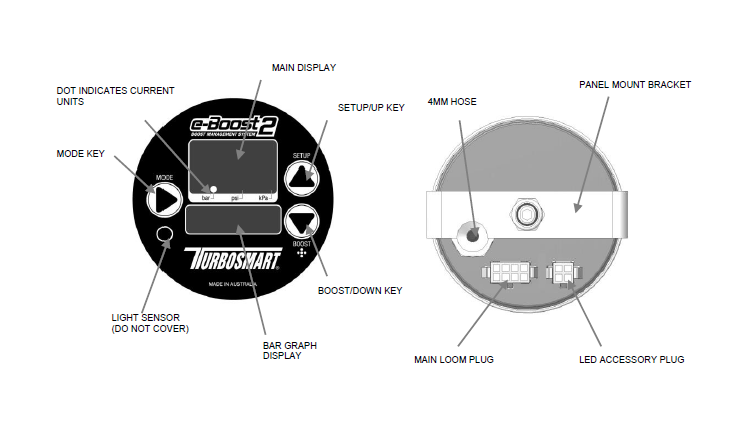

How to Install a e-Boost2 Boost Controller, 60mm - Black on your 1979-2015 Mustang

Shop Parts in this Guide

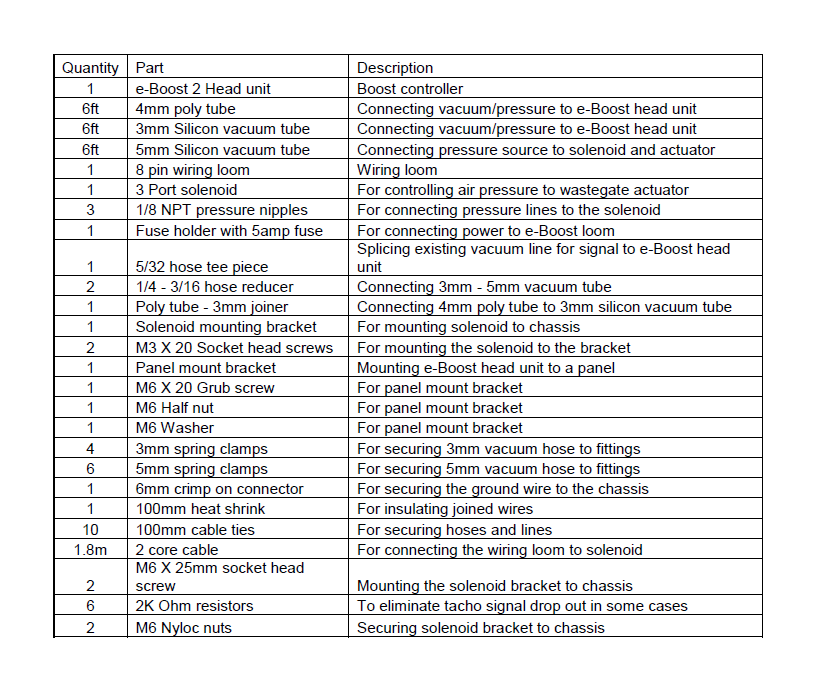

Parts list

BEFORE YOU START – IMPORTANT NOTES

- Turbosmart recommends that your e-Boost2 is fitted by an appropriately qualified technician.

- Consult your local tuning specialist before setting your boost pressure, setting boost beyond your engines capability can result in severe engine damage or failure!

- Turbosmart recommends that the engines Air/Fuel ratio is checked once the desired boost pressure is set, any increase in boost pressure can cause the engine to run lean resulting in severe engine damage or failure.

- Turbosmart recommends that the e-Boost2 is not used in conjunction with any type of “Draw Through” Fuel System.

- Turbosmart recommends that boost pressure is set using a Dynamometer and not on public roads.

- The e-Boost2 may not be able to completely compensate for a drop in boost pressure at high RPM due to the turbocharger operating beyond its maximum efficiency range i.e. incorrect turbocharger sizing or excessive exhaust backpressure.

- The e-Boost2 cannot compensate for increases in boost pressure at high RPM due to inadequate waste gate flow capacity; the turbo system must maintain a steady base boost curve.

- The e-Boost2 cannot be used with external waste gates that are in a poor, worn or non-serviceable condition.

- For best results your turbocharger should be correctly sized for your application.

- A Turbosmart Fuel Cut Defender may need to be used in conjunction with your e-Boost2, Please check out our website at www.turbosmartonline.com or your nearest Authorised Turbosmart Dealer for more information on Fuel Cut Defenders.

- Erratic operation of electronic parts can be caused by Electro Magnetic Interference (EMI). EMI can be generated by aftermarket ignition systems such as CDI which, if wired incorrectly, generate large amounts of EMI through the vehicles electrical system. This can cause items such as ECU’s and boost controllers to be effected. Please follow ignition system installation instructions VERY carefully to avoid EMI affecting the e-Boost.

INSTALLATION

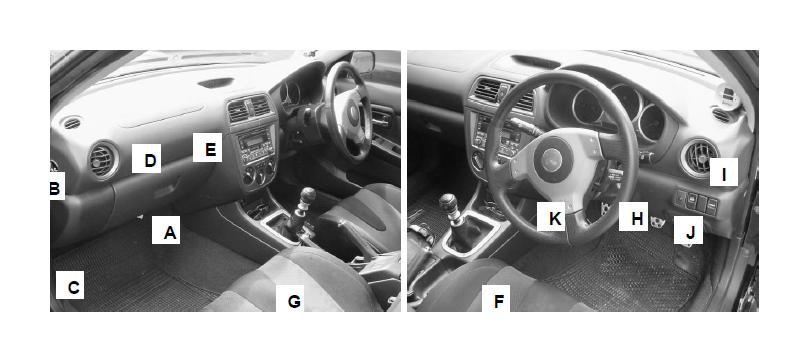

Mounting the e-Boost 2

The e-Boost2 is not waterproof and must be mounted inside the cabin. The unit has an operating temperature range of -5OC to 70OC.

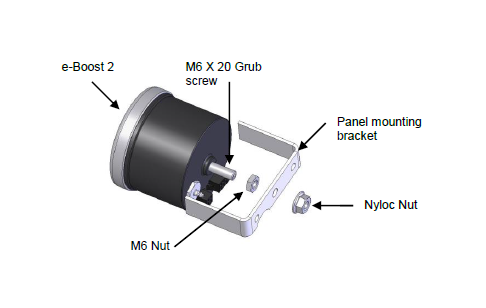

The e-Boost2 is designed to be panel mounted with the bracket supplied. Alternatively the 60mm e-Boost2 can be mounted using the Turbosmart 60mm dash mounting accessory, pod or “A pillar” mounts. If you have the 66mm e-Boost2 it can be mounted using the Turbosmart 66mm dash mount accessory. The Turbosmart dash mounting accessory offers full tilt and swivel adjustment.

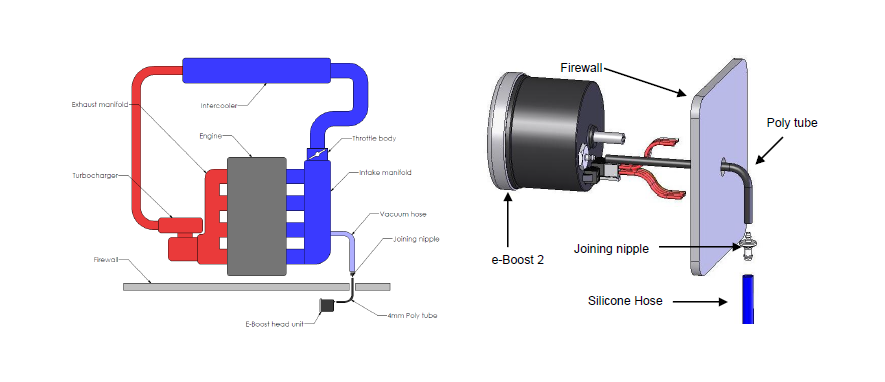

The E-Boost 2 requires a vacuum/pressure signal from the intake manifold to function. A combination of poly tube and silicone hose is used to connect the E-boost 2 to a adequate vacuum/pressure signal. Route the poly tube from the E-boost 2 head unit through the fire wall approximately 100mm (4”) only as the poly tube is not rated to the high temperatures of the engine bay.

• Use the connecting barb to join the poly tube to the 3mm ID silicon hose at the firewall/bulkhead. Ensure the poly tube is pressed all the way onto the connecting barb

• Route the silicon hose through the engine bay and connect it to a pressure/vacuum signal from the inlet manifold. Use the supplied tee piece if necessary.

• Secure all connections with the supplied hose clamps

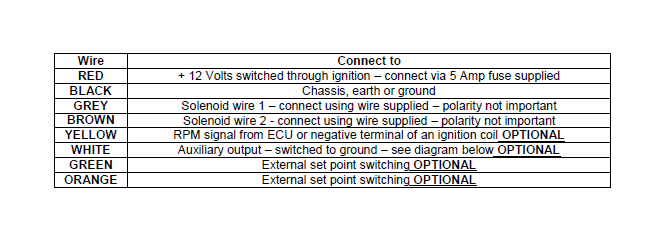

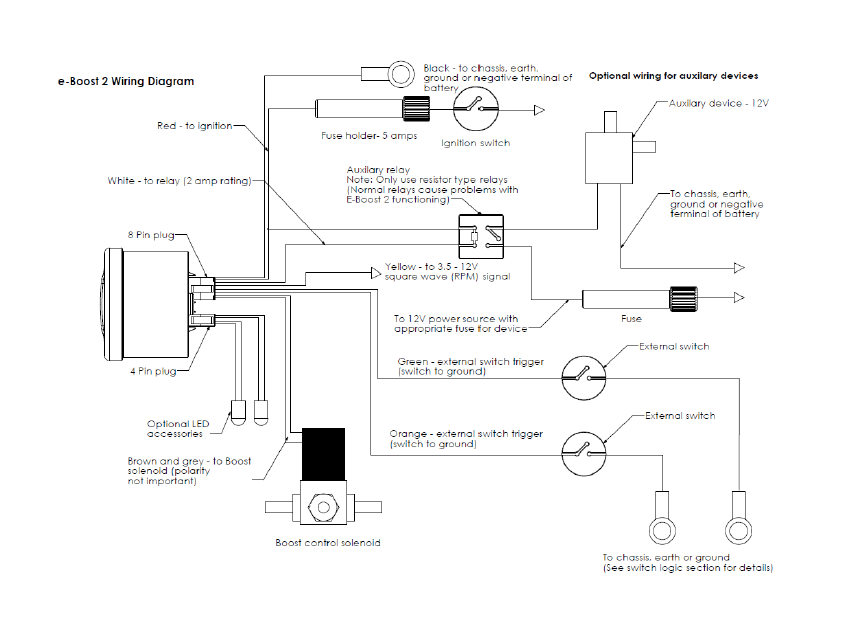

Wiring

- The e-Boost2 must be connected to a typical automotive12 volt negative earth electrical system.

- Soldering or Crimp on electrical connectors must be used on all electrical connections

- Unused wires must be insulated with electrical tape so that they do not touch other wires or the chassis

- Refer to the following table and diagram for detail on wiring the e-Boost2.

Installing the e-Boost 2 Solenoid

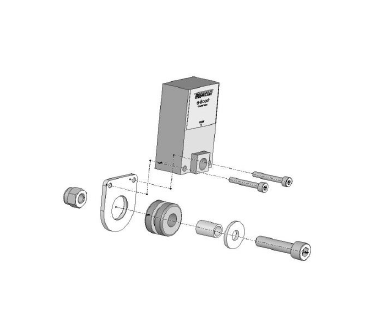

- The e-Boost2 solenoid is rated to a maximum temperature of 100 degrees Celsius (212 degrees Fahrenheit), ensure that it is mounted a minimum of 250mm (10 Inches) away from the heat of the turbo or exhaust manifold, otherwise heat shielding maybe required.

- Mount the e-Boost2 solenoid in an appropriate position in the engine bay with the mounting kit supplied.

- Fit the rubber grommet inside the mounting plate. Slide the sleeve inside the grommet. Use the M3 screws to bolt the solenoid to the mounting bracket – Note use loctite on the threads to secure. Use the M6 screw, washer and Nyloc nut to mount in a suitable location in the engine bay.

- The e-Boost 2 head unit is capable of controlling two solenoids. The use of twin solenoids is not necessary but is recommended in twin turbo setups on V configuration engines as this reduces the length of hose required for plumbing which aids in response and control of the wastegates.

- The solenoid must be connected to a pressure only source which must be located before the intercooler, ideally off the compressor cover of the turbocharger. The air temperature before the intercooler is less affected by ambient conditions which will give you more consistent boost control.

INTERNAL WASTEGATE CONNECTION

WARNING! Changing to different connection methods can cause a higher than expected increase in boost pressure. Turbosmart recommends adjusting your boost controller back to its minimum setting and measuring the new minimum boost pressure achieved by the new setup before increasing your boost again.

Note: If your vehicle is fitted with a factory boost control solenoid, the hoses that run from the solenoid to the pressure source and to the wastegate actuator must be disconnected from the solenoid. Leave the solenoid plugged into the wiring loom so that the ECU is not affected.

Most factory turbocharged vehicles use an internal waste gate system to control boost pressure. The e-Boost2 controls boost pressure by controlling the pressure signal that the waste gate actuator receives from the turbocharger. Please note that the e-Boost2 cannot be used to obtain a boost pressure lower than the standard waste gate actuator’s pressure setting.

• Some factory hoses have a small restrictor fitted inside them, if the factory hoses are reused over boosting or boost spiking may occur.

• Secure all connections with hose clamps.

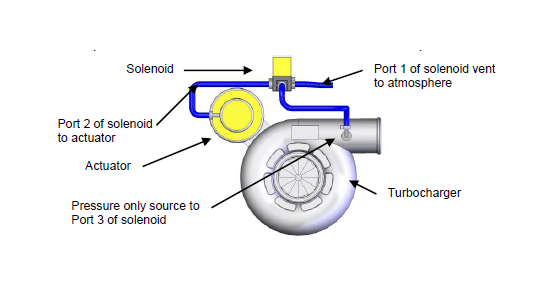

Single solenoid, single turbocharger hook up (Basic single internal wastegate setups)

• Port (1): vents pressure from the solenoid. Connect this hose to the intake side of the turbo, between the air cleaner and the inlet of the turbocharger. Otherwise connect a short piece of the silicon hose and face the vent downwards to stop water or debris entering the solenoid. •

Port (2): to the internal wastegate actuator •

Port (3): to pressure only source

If you are unable to achieve your desired boost pressure, it is normally due to exhaust manifold backpressure forcing the internal waste gate to open. To increase your boost pressure further, fit a higher pressure waste gate actuator to increase your minimum boost pressure.

WARNING! Fitting a higher pressure waste gate actuator may cause a higher than expected increase in boost pressure.

Turbosmart recommends resetting the boost set point values to Zero and measure the new minimum boost pressure before increasing your boost set point values.

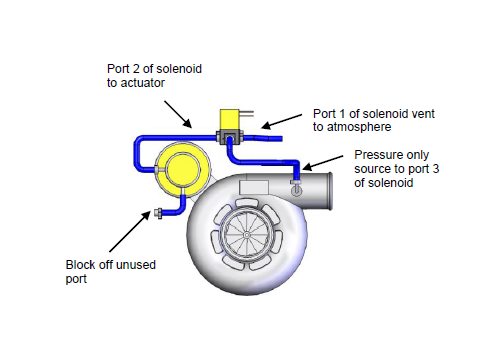

Internal wastegates with 2 ports

• Port (1): vents pressure from the solenoid.

• Port (2): connect to one of the ports of the actuator

• Port (3): to pressure only source

• Block off unused port on the actuator with suitable blank

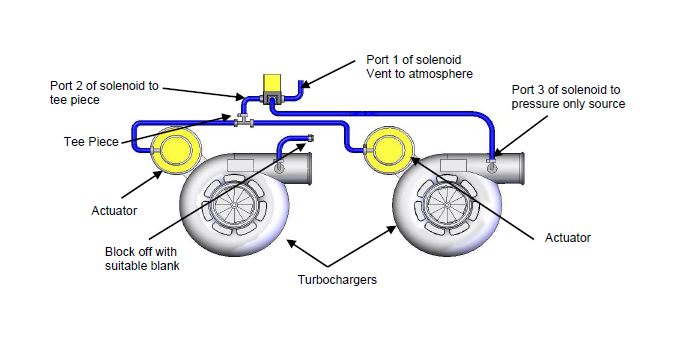

Single solenoid, twin parallel turbocharger hook up

(For straight configuration twin parallel turbocharger engines E.g. RB26DETT)

• The e-Boost2 is capable of controlling twin internal wastegate turbochargers with a single solenoid.

• This method is used when the turbochargers are mounted close to each other allowing the solenoid to be mounted close to both actuators

• Each solenoid port is connected as follows:

Port (1): vents pressure from the solenoid. Connect this hose to the intake side of the turbo, between the air cleaner and the inlet of the turbocharger. Otherwise connect a short piece of the silicon hose and face the vent downwards to stop water or debris entering the solenoid.

Port (2): to tee piece that feeds both actuators

Port (3): to pressure only source

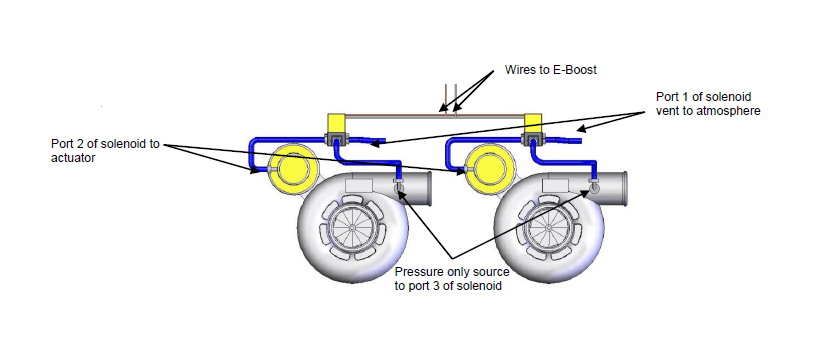

Twin solenoid, twin parallel turbocharger hook up

(For V configuration twin parallel turbocharger engines E.g. V6, V8 etc)

• The e-Boost2 is capable of controlling two solenoids for twin parallel turbocharger setups.

• This method is used when there is a great distance between the wastegates. This allows the solenoids to be mounted close to the wastegates to minimise the length of hose used and to maximise response

• You will need a second solenoid for this method (TS-0301-3003)

• Connect the grey wire from the e-Boost wiring loom to one of the wire from each solenoid.

• Connect the brown wire from the e-Boost wiring loom to the remaining wire from each solenoid.

• Each solenoid port is connected as follows:

Port (1): vents pressure from the solenoid. Connect this hose to the intake side of the turbo, between the air cleaner and the inlet of the turbocharger. Otherwise connect a short piece of the silicon hose and face the vent downwards to stop water or debris entering the solenoid.

Port (2): to the internal wastegate actuator

Port (3): to pressure only source

EXTERNAL WASTEGATE CONNECTION

The first method of installation is a one port connection. If the desired boost level is not achieved i.e. boost level is too low, or not controllable, it is recommended that the wastegate spring be changed to a spring which is closer to the desired boost pressure or to trial a 2 port connection method.

There are 3 different 2 port connection methods that can be trialled to achieve different results. The 2 port method (1) can be used if there is high exhaust manifold back pressure forcing the valve open. The 2 port method (2) allows the user to achieve the maximum boost pressure their turbo system is capable of. If a wide range of boost pressures is desired i.e. 5 – 40 PSI, the 2 port method (3) with a 4 port solenoid (sold separately – TS-0301-2003) might be needed.

A single solenoid can be used to control twin wastegates in a twin turbo setup but it is recommended that twin solenoids are used in twin turbo setups to reduce the length of the pressure hoses to aid in control and response of the wastegates.

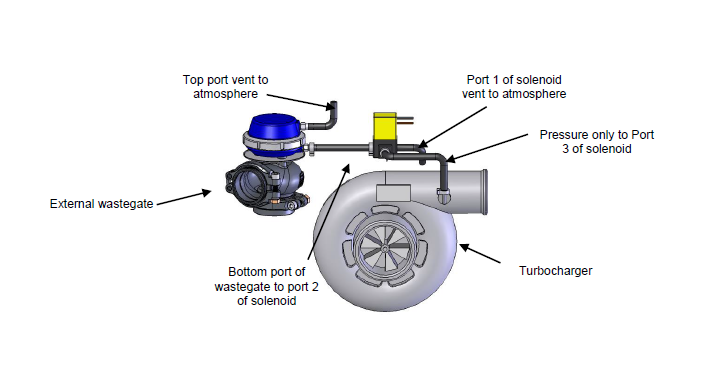

Single port, single solenoid, single turbo connection Method

(Basic single wastegate setup)

Port 1 of solenoid vent to atmosphere

Port 2 of solenoid to bottom port of wastegate

Port 3 of solenoid to Pressure only source

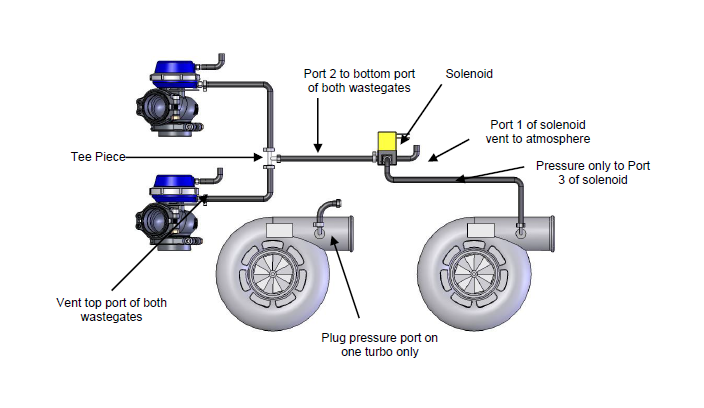

Single port, single solenoid, twin turbo connection Method

(For straight configuration twin parallel turbocharger engines E.g. RB26DETT)

Port 1 of solenoid vent to atmosphere

Port 2 of solenoid to bottom port of wastegate

Port 3 of solenoid to Pressure only source

Block off other turbocharger pressure port (if needed)

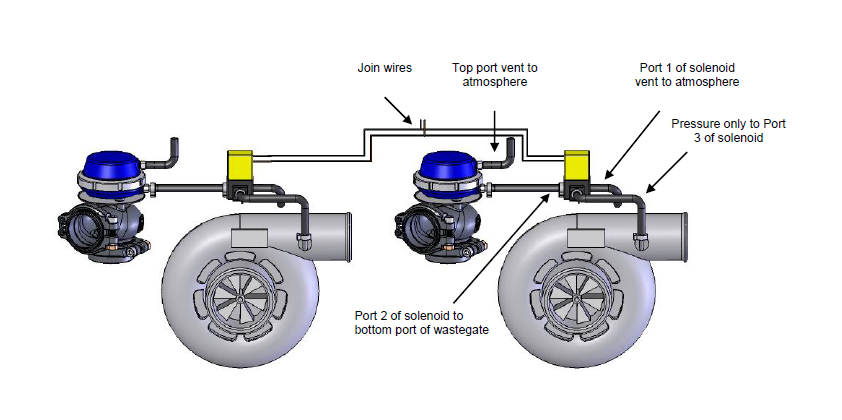

Single port, twin solenoid, twin turbo connection Method

(For V configuration twin parallel turbocharger engines E.g. V6, V8 etc)

Port 1 of solenoid vent to atmosphere

Port 2 of solenoid to bottom port of wastegate

Port 3 of solenoid to Pressure only source

Join the wires from both solenoids together (polarity not important) and then connect them to the brown and grey wires of the wiring loom

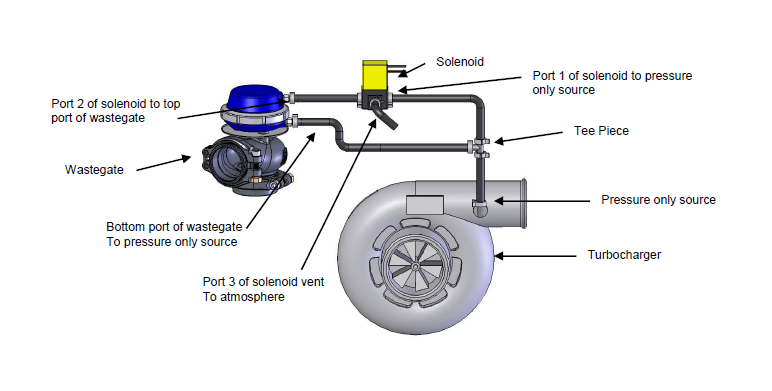

Two port, single solenoid, single turbo connection Method

(For controlling boost on a single turbo, single wastegate, single solenoid turbo system with high back pressure)

*NOTE: An increase in your minimum boost pressure is expected when using any of the 2 port connection methods. Ensure all boost set point values and gate pressure values are set to Zero and measure the new minimum boost pressure achieved by this method before increasing your Boost Set Point values.

Connect the bottom port of the wastegate and Port 1 of the solenoid to a Pressure only source via a tee piece

Port 2 of the solenoid to the top port of the wastegate

Port 3 of solenoid vent to atmosphere

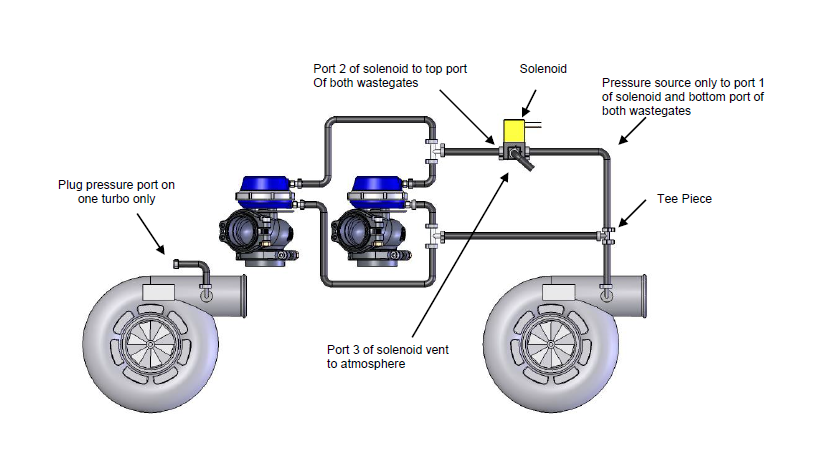

Two port, single solenoid, twin turbo connection Method

(For controlling boost on a twin turbo, twin wastegate, single solenoid turbo system, on a straight configuration engine with high back pressure)

• Connect the bottom port of the wastegates and Port 1 of the solenoid to a Pressure only source via tee pieces

• Port 2 of the solenoid to the top port of the wastegates via tee pieces

• Port 3 of solenoid vent to atmosphere

• Block off other turbocharger pressure port (if needed)

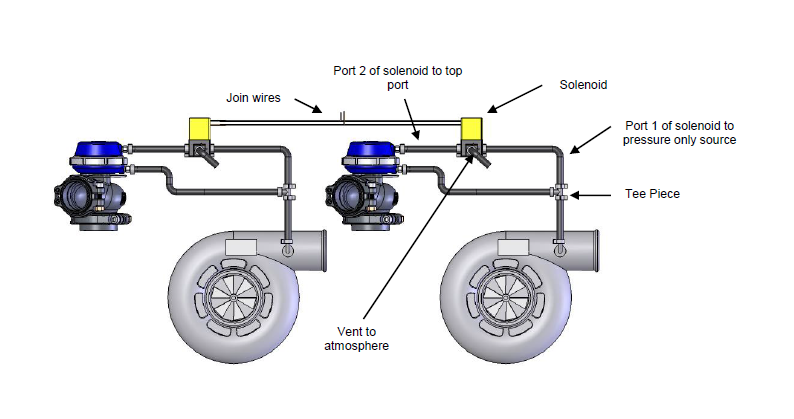

Two port, twin solenoid, twin turbo connection Method (For controlling boost on a twin turbo, twin wastegate, twin solenoid turbo system, on a V configuration engine with high back pressure)

• Connect the bottom port of the wastegate and Port 1 of the solenoid to a Pressure only source via a tee piece

• Port 2 of the solenoid to the top port of the wastegate

• Port 3 of solenoid vent to atmosphere

• Join the wires from both solenoids together (polarity not important) and then connect them to the brown and grey wires of the wiring loom

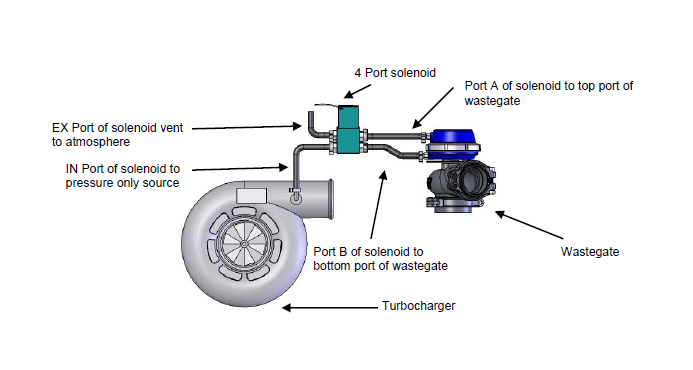

Two port, single 4 port solenoid, single turbo connection Method

(For obtaining a wide range of boost pressures e.g. 5 – 40 PSI. This connection method has varying degrees of success depending on turbo system)

• Port A of solenoid to Top port of wastegate

• Port B of solenoid to Bottom port of wastegate

• EX port of solenoid vent to atmosphere

• IN port of solenoid to Pressure only source

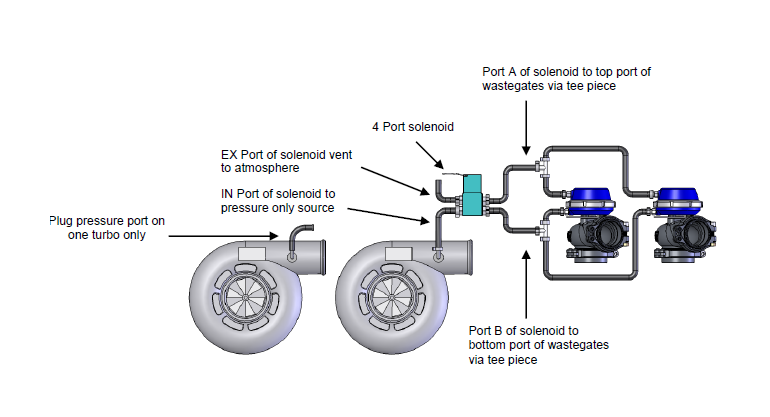

Two port, single 4 port solenoid, twin turbo connection Method

(For obtaining a wide range of boost pressures e.g. 5 – 40 PSI on a straight configuration engine. This connection method has varying degrees of success depending on turbo system)

• Port A of solenoid to Top port of wastegates

• Port B of solenoid to Bottom port of wastegates

• EX port of solenoid vent to atmosphere

• IN port of solenoid to Pressure only source

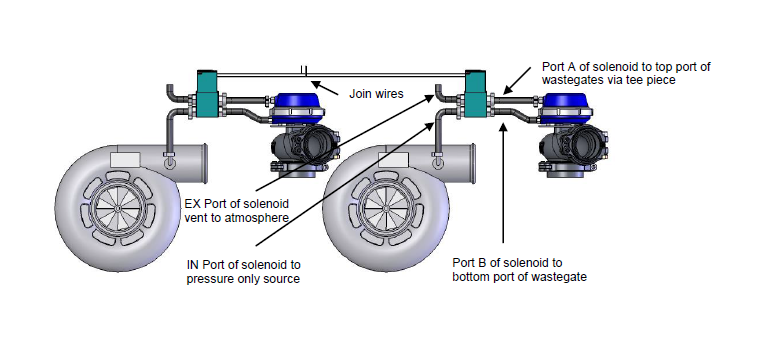

Two port, twin 4 port solenoid, twin turbo connection Method

(For obtaining a wide range of boost pressures e.g. 5 – 40 PSI on a V configuration engine. This connection method has varying degrees of success depending on turbo system)

• Port A of solenoid to Top port of wastegates

• Port B of solenoid to Bottom port of wastegates

• EX port of solenoid vent to atmosphere

• IN port of solenoid to Pressure only source

• Join the wires from both solenoids together (polarity not important) and then connect them to the brown and grey wires of the wiring loom

BASIC OPERATION

The e-boost2 is turned on by switching on your ignition.

Turning off the e-Boost2: The e-Boost2 is turned off by pressing and holding the MODE button for five seconds or turning off your ignition. If you turn the unit off with you ignition on pressing the MODE button momentarily will turn the unit back on.

Display Mode: Your e-boost2 has a display mode that may be used if showing your car. Pressing the UP and DOWN buttons together quickly will enter the display mode. “e-boost2” will scroll across the screen and the bar graph will scroll up and down. Pressing the UP and DOWN buttons together will exit display mode.

Live Mode: When the e-Boost2 is turned on, it automatically goes into live mode and displays the current vacuum/boost.

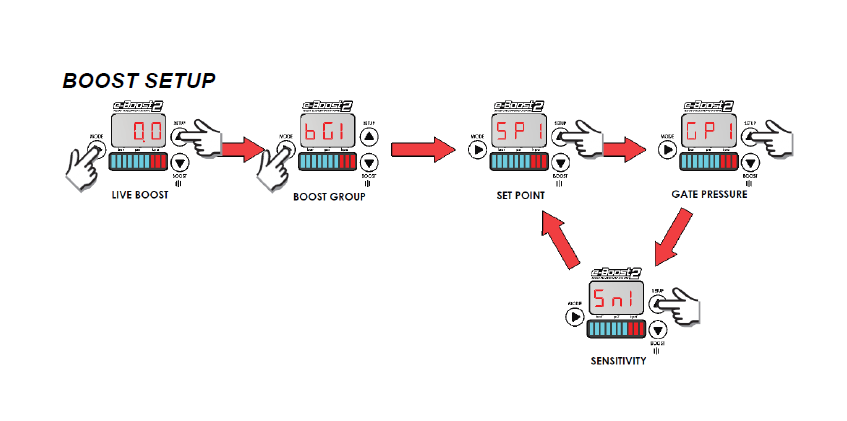

Boost setup Menu: To enter the boost setup menu, in live mode, press MODE and BOOST/DOWN key ONCE at the same time.

Setup Menu: To enter the setup menu, in live mode, press MODE and SETUP/UP Key ONCE at the same time.

Navigation and adjusting values in menus: Use the UP and DOWN keys to scroll or adjust values up and down.

Entering menus: Press the MODE key ONCE to enter any menu.

Saving settings: When adjusting values, once the desired value is selected, press the MODE key ONCE to save the value.

Exiting menus: When in any menu, HOLDING the MODE key will bring you back to the previous menu without saving the setting

13 www.TURBOSMARTONLINE.

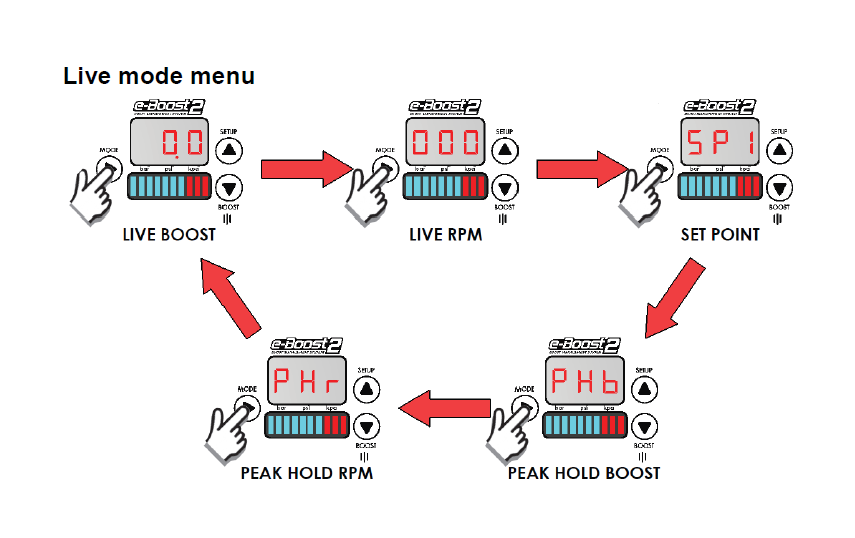

When the e-Boost2 is powered up, the display will automatically go into live mode. Pressing MODE ONCE will scroll through the live mode menu.

Live Boost: Live boost is the default display and will display live boost or vacuum readings.

Live RPM: Live RPM will display the current RPM of the engine. If you have not connected your RPM signal then this parameter will

not appear.

Set Point: Shows the current set point value the unit is set to.

Peak Hold Boost: This function records the peak boost pressure the unit has measured. Each time a higher pressure is produced the previous figure is discarded and the new pressure is recorded (value will reset when the unit is switched off)

Peak Hold RPM: This function records the peak RPM the unit has measured. Each time a higher RPM is produced the previous figure is discarded and the new peak RPM is recorded (value will reset when the unit is switched off)

INITIAL SETUP AND FUNCTIONALITY

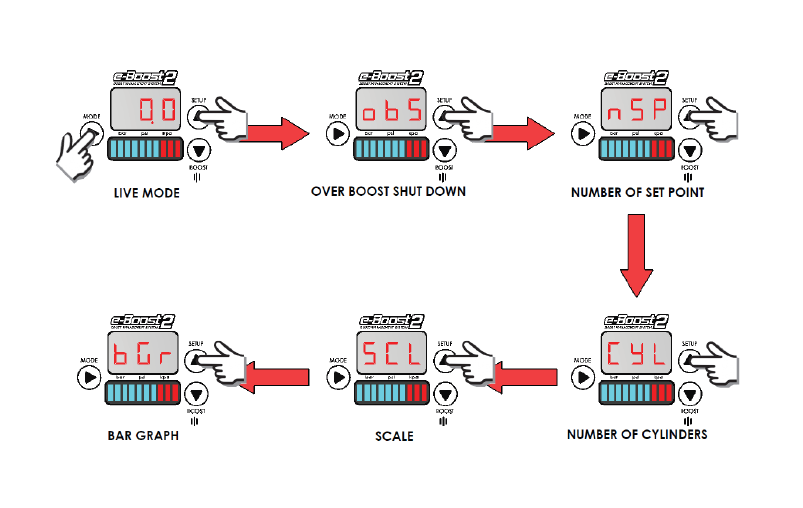

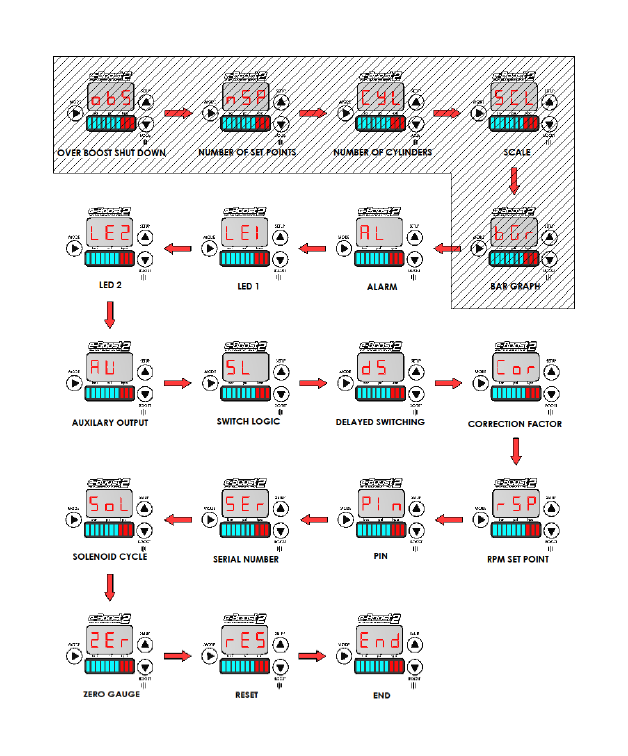

Entering setup menu

Enter Setup menu by pressing MODE and SETUP/UP at the same time.

Setting obS (Over boost shutdown):

THIS MUST BE SET UP FIRST OR YOUR ENGINE WILL NOT PRODUCE ANY BOOST

Turbosmart recommends that this function is used in conjunction with another form of Over-boost protection such as fuel/ignition cut or over-boost valve. The over-boost function will not stop an over-boost scenario if there is a mechanical failure on the car that inhibits the e-Boost from controlling the wastegate or if electromagnetic interference due to incorrect wiring causes electrical interference to the e-Boost.

If the obS is triggered the e-Boost2 begins to reduce the boost pressure to half of that set in the obS parameter. Once this safe pressure is achieved the e-Boost will return to normal operation. obS must be set to a level at least 2.2psi (0.15 bar or 15kPa) above the highest boost pressure. When the obS is triggered obS will flash on the display to indicate that your boost pressure has reached the over boost shut down value. obS will continue to flash on the display until the pressure has been reduced to half that set in obS and the unit has returned to normal operation. obS will flash on the screen when triggered in live mode and when a set point is being edited under boost pressure but not inside the boost or setup menus until they are exited.

The obS is factory set to 7 psi (0.48 bar or 48 kPa), so you must enter a figure in order for the e-Boost to produce more than a standard boost pressure. The purpose of this feature is to protect your engine against accidentally entering a boost set point value that is too high, preventing a dangerously high boost pressure. Extreme care should be taken when setting this parameter. Turbosmart recommends that you seek advice from an appropriately qualified technician with regard to the obS setting.

Press MODE to enter the menu and adjust the values using the UP and DOWN keys. Press MODE again to save the desired setting.

Setting nSP (Number of set points):

The e-Boost2 is capable of controlling up to 6 individual boost groups. Setting nSP to a value from 1-6 will then enable that number of boost groups (and their associated set point, gate pressure and sensitivity) in the boost menu and live mode. Press MODE to enter the menu and adjust the values using the UP and DOWN keys. Press MODE again to save the desired setting.

Setting CYL (Number of Cylinders):

If you have connected the yellow RPM wire to an RPM signal from your ECU or negative terminal of an ignition coil you will need to input the number of cylinders / rotors in order to configure the RPM signal correctly i.e. the number of pulses per revolution being picked up from the RPM output of the ECU. The number of cylinders available is between 1 and 16. The RPM input can accept a square wave signal between 3.5 and 12V. Twin rotor and triple rotor engines can be configured as 4 and 6 cylinders respectively. Press MODE to enter the menu and adjust the values using the UP and DOWN keys. Press MODE again to save the desired setting.

Setting SCL (Scale):

The e-Boost2 readout can be configured in either bar, psi or kPa, the default setting is in psi. This allows you to tailor the readout to suit your own preference. Note that when the psi scale is selected and the e-Boost2 is under vacuum conditions the display will read in inches of Mercury (inHg) not negative psi. Press MODE to enter the menu and adjust the values using the UP and DOWN keys. Press MODE again to save the desired setting.

Setting bGr (Bar graph):

The e-Boost2 bar graph can be configured to indicate a pressure between zero and full scale (60 psi). The bar graph has ten segments, seven blue segments and three red segments. When seven segments are illuminated the pressure that has been programmed in this parameter has been reached. The bar graph is factory set to 15 psi. The desired display pressure can be adjusted to your preference and is typically set at your maximum boost level. Press MODE to enter the menu and adjust the values using the UP and DOWN keys. Press MODE again to save the desired setting.

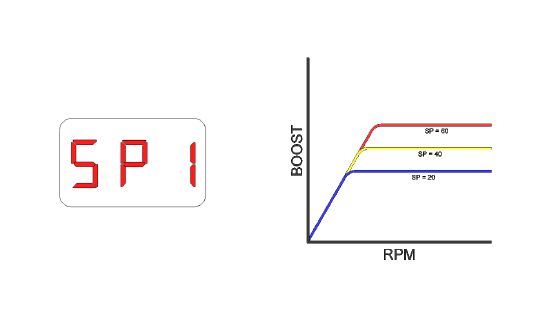

Setting SP1 (Set point):

The SP value determines the DUTY CYCLE the solenoid will operate at when the gate pressure is reached. The SP value is not the amount of boost pressure your turbo will produce. This is a value between 0 – 99. The larger the value, the more boost the turbocharger will produce. Start the setup by increasing the SP value to 20. Bring the car onto boost and see what the maximum boost pressure is. Increase the value in small increments until you achieve your desired boost pressure. The SP value can also be adjusted while the car is on boost however, instead of the SP value being displayed, the boost pressure will be displayed so you know what pressure you are achieving. This is the easiest way to set your set points. Press MODE to enter the menu and adjust the values using the UP and DOWN keys. Press MODE again to save the desired setting.

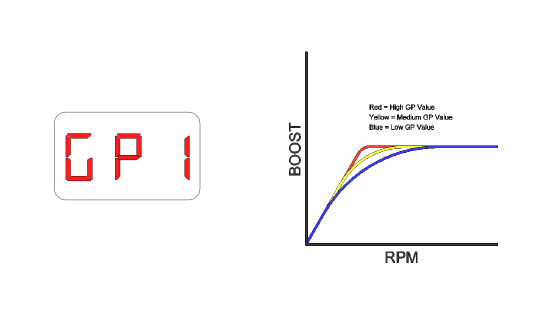

Setting GP1 (Gate pressure):

This feature helps bring boost on faster at lower rpm and will give an increase in torque. Start by setting the gate pressure 5 PSI below the desired boost pressure with the corresponding SP value e.g. if the desired boost pressure is 15 PSI, set the gate pressure to 10 PSI first and adjust from there. Adjust the value higher to increase the response of the turbocharger or decrease the value to reduce the response. If this setting is too close to target boost, you will get a boost spike. Press MODE to enter the menu and adjust the values using the UP and DOWN keys. Press MODE again to save the desired setting.

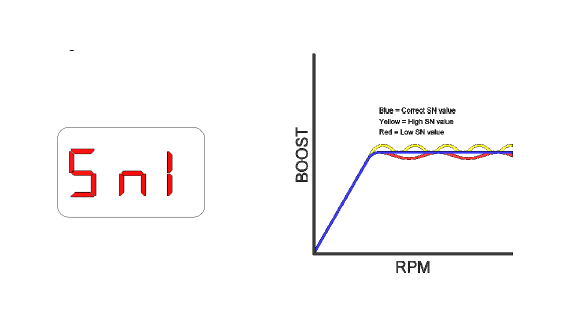

Setting SN1 (Sensitivity):

The sensitivity is how sensitive the e-Boost2 is to changes in the boost curve. Under normal circumstances the sensitivity is left at the factory set level of 20. If your boost curve is wavy through the rev range, reduce the sensitivity, if your boost curve drops off at the end of the rev range, increase the sensitivity. Note: do not increase this value higher than 30. Press MODE to enter the menu and adjust the values using the UP and DOWN keys. Press MODE again to save the desired setting.

13) Hold MODE to exit the Boost Group.

14) Repeat steps 10 – 13 for each Boost Group.

15) Once all Boost Groups are set, Hold MODE in the Boost Group menu to enter Live Mode

ADVANCED FUNCTIONALITY

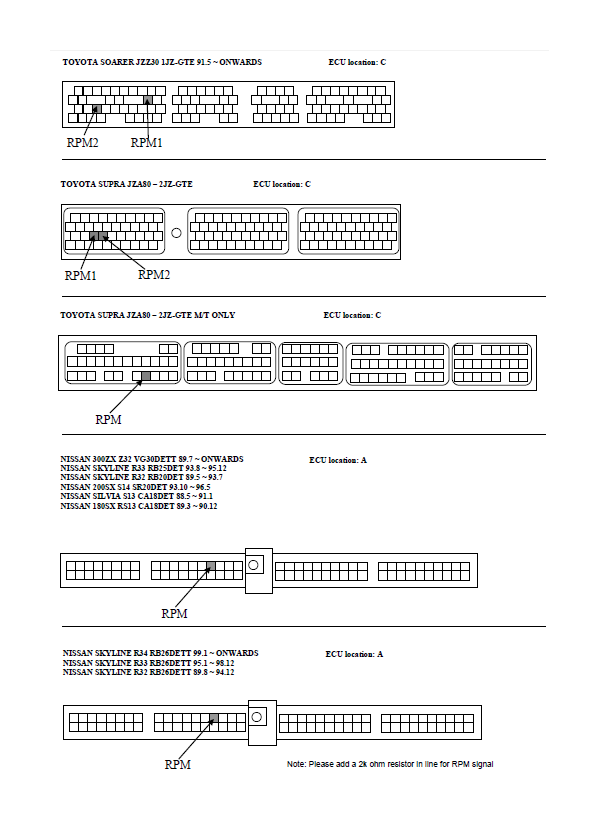

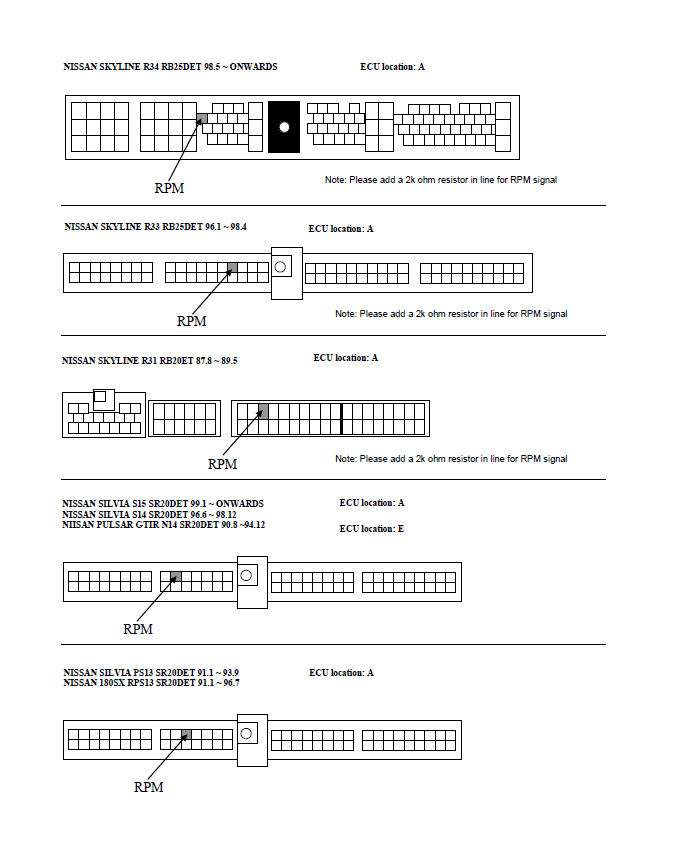

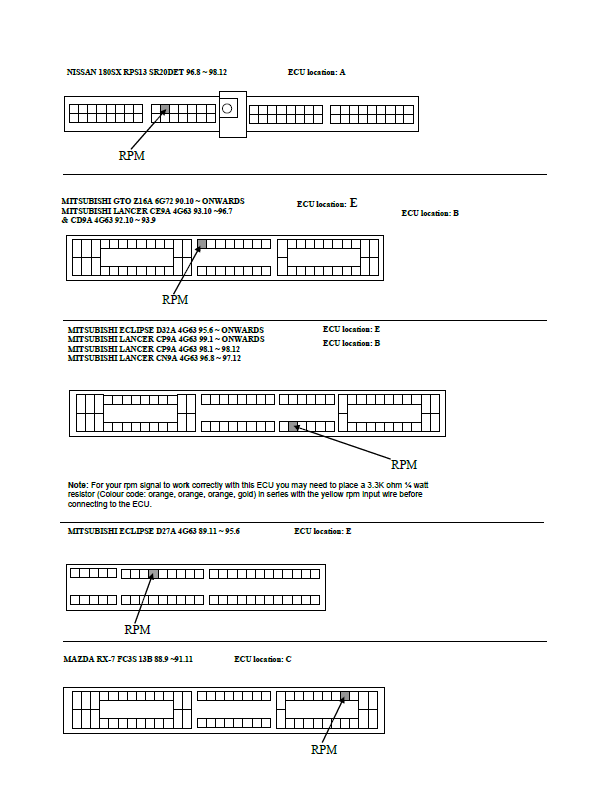

RPM Signal Connection (OPTIONAL)

RPM signal connection is ONLY for Tacho mode, RPM set point mapping, Boost correction, shift light function and other advanced features. Turbosmart recommends your RPM signal be connected by an appropriately qualified technician or automotive electrician. For further information consult your vehicle’s manuals or your local automotive electrician. The e-Boost2 is ONLY able to accept an RPM signal in the form of a square wave that is switching between 0V and 3.5-12 volts.

The following points should be followed to connect your RPM signal to an ECU pin.

- Locate your ECU RPM signal wire and splice into the signal wire coming from your ECU.

- Check the output you are splicing into is a square wave that is switching between switching between 0V and 3.5-12 volts with an appropriate meter.

- Connect the yellow RPM wire from the e-Boost to the spliced section of the ECU RPM out.

- Turn on the e-Boost2 and configure your signal to the number of cylinders or rotors your engine has using the CYL (cylinder) parameter located in the setup menu.

- In live mode with your engine running press mode once to show live RPM. The display should be reading RPMx100 e.g. 015 on the display indicates 1500 RPM. If the display is not reading correctly re-check the cylinder configuration in the setup menu.

- Note: If the OEM tachometer does not display RPM after installing the E-Boost 2, a 2 ohm or higher resistor needs to be installed in line between the ECU RPM output pin and the E-Boost 2.

The following points should be followed to connect your RPM signal to the negative terminal of an ignition coil. NOTE: Caution should be exercised when connecting to the negative terminal of an ignition coil and Turbosmart recommends an ECU connection where possible. IMPORTANT! The RPM signal should not be connected to a coil of a capacitive discharge ignition (CDI) system.

- Check the signal from the negative terminal is a square wave that is switching between switching between 0V and 3.5-12 volts with an appropriate meter. If the voltage is below 3.5V (coil trigger signals tend to have a very low voltage) the e-Boost will not read a signal. In this case, a signal amplifier (also known as a tach adapter) must be used to boost the signal.

- Connect the RPM signal wire from the e-Boost2 to the negative terminal of an ignition coil or tach adapter (which ever method is used).

- Turn on the e-Boost2 and configure your signal to the number of cylinders or rotors your engine has using the CYL (cylinder) parameter located in the setup menu

- In live mode with your engine running press mode once to show live RPM. The display should be reading RPMx100 e.g. 015 on the display indicates 1500 RPM. If the display is not reading correctly re-check the cylinder configuration in the setup menu.

SL (Switch Logic)

The e-Boost2 is capable of 9 different methods of boost switching.

IMPORTANT! Before setting up your boost group switching you should know what boost pressure you achieve with each set-point setting in its relevant boost group. For example if you want to run four different boost levels you should set up four groups and test what each of your boost levels are before setting up switching between each boost group.

ISP (Internal switching point): Switching between boost groups is achieved using the UP and DOWN Keys

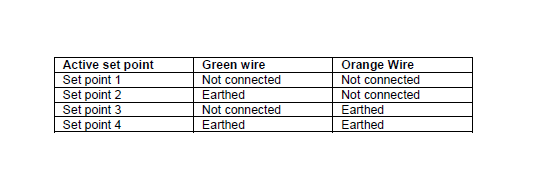

ESP (External switching point): Up to 4 boost groups can be selected directly by externally grounding or earthing the green and/or orange wires from the e-Boost2 loom to the chassis. The appropriate wire corresponding to the set point you wish to select is shown in the table below.

BOD (Boost on demand): Allows you to select a boost set point for an inputted value of time before returning to the previous set point. When the BOD function is activated within the switch logic menu, an additional sub-menu will appear in bG2 and bG3 of the boost menu called bd2 and bd3. bd2 is the value of time in seconds, bG2 will be selected before returning to the previous set point. Bd3 is the value of time in seconds, bG3 will be selected before returning to the previous set point.

• Earthing the green wire will trigger bG2 for the inputted value of time

• Earthing the orange wire will trigger bG3 for the inputted value of time

• Maximum time that a boost group can be selected is 99 seconds

• The boost and setup buttons on the e-Boost2 unit will function as normal in ISP mode.

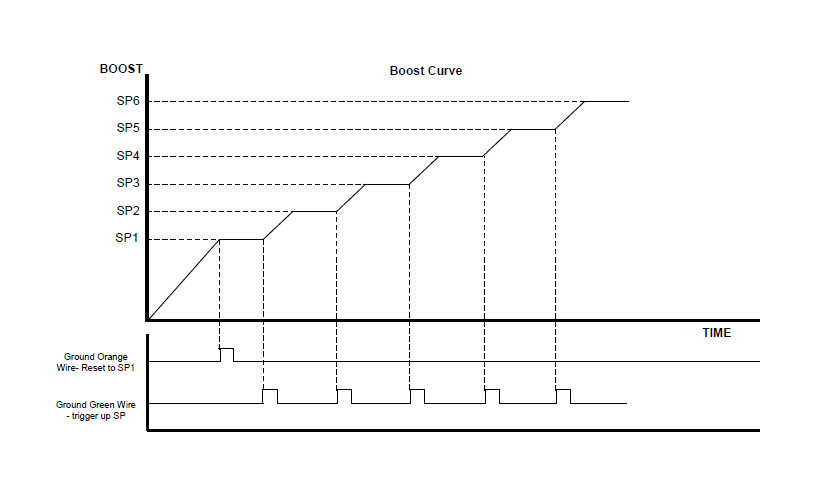

SSA (Sequential switching function A): Allows you to sequentially switch between different boost settings. This switch logic could be applied in a situation where you want to have a different boost level in each gear.

• Earthing the green wire with a switch will scroll up a single set point.

• Earthing the green wire again will switch up another single set point.

• The maximum number of set points that can be switch up to is determined by nSP in the setup menu.

• Once the maximum set point is reached through switching further switching not increase the set point any higher.

• Earthing orange wire with a switch will reset and return to SP1.

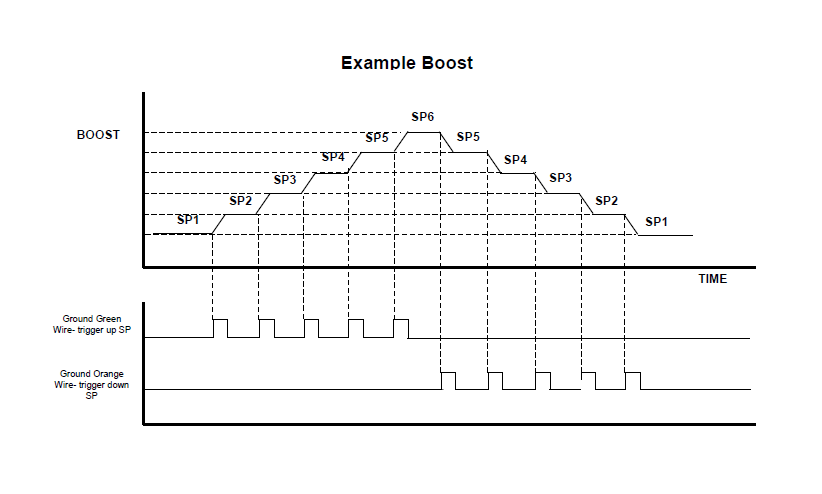

SSB (Sequential switching function B): Sequential Switching Function B allows you to sequentially switch up and down between different boost settings using external switches. This switch logic could be applied in a situation where you want to have a different boost levels in each gear.

• Earthing the green wire with a switch will switch up a single set point.

• Earthing the green wire again will switch up another single set point.

• The maximum number of set points that can be switch up to is determined by nSP in the setup menu.

• Once the maximum set point is reached through switching (note: will only switch up to SP6).

• Earthing orange with a switch will wire switch down a single set point.

• Earthing the orange wire again will down another set point. (note: will only switch down to SP1).

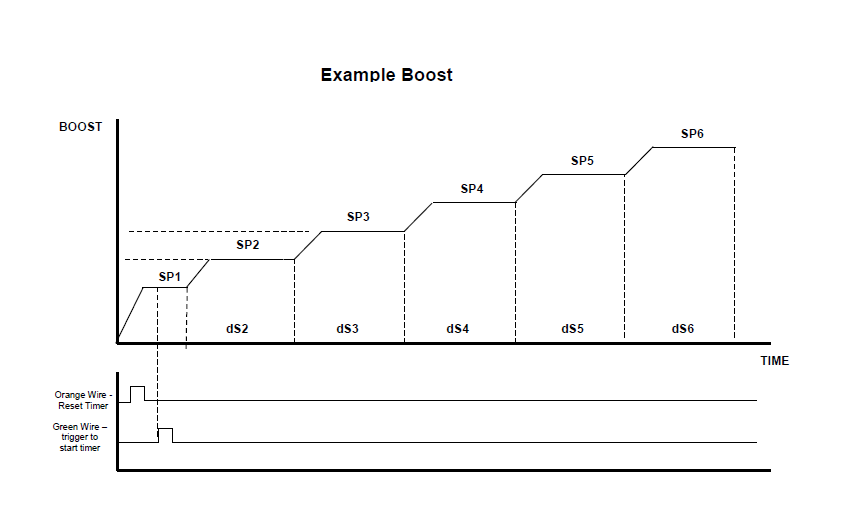

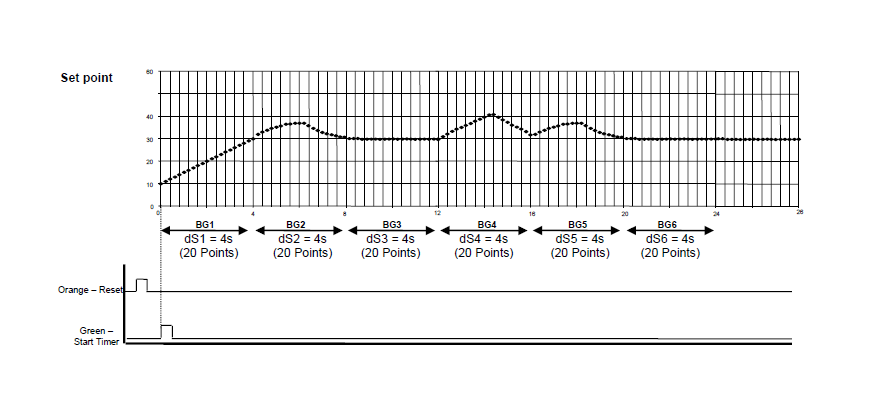

SSC (Sequential switching function C): Timed sequential switching function C allows the boost groups/set-points to be active then switched at predetermined time intervals. This switch logic could be applied in a drag racing situation where you want to switch boost levels at known time intervals within your elapsed time (ET).

• With SSC active dS1-dS6 will appear in each boost group.

• These time intervals can be entered as the amount of time you want each set point to be active before switching to the next set point.

• Time delays are in increments of 1/10th of a second, with the maximum allowable being 99 seconds.

• dS1 will refer to the amount of time SP1 is active before switching to SP2, dS2 to the amount of time SP2 is active before switching to SP3 and so on.

• Earthing the orange wire with a switch will reset the timer and switch to SP1/BG1.

• Earthing the green wire will start the timer and the time interval dS1 during which SP1 will be active.

• At the end of the time interval dS1 the unit will switch to SP2 and SP2 will be active for the time interval dS2.

• The same procedure will happen for all active set points (determined by the nSP parameter in the setup menu)

• Once the last time interval has ended the unit will continue to operate at the final set point.

• Note to skip a set point/boost group set the dS parameter for that group to equal zero.

• This is a solely time based switching method and is not dependant on switching except for the reset to SP1 (earthing the orange wire) and a GO (earthing the green wire) which will start the timer.

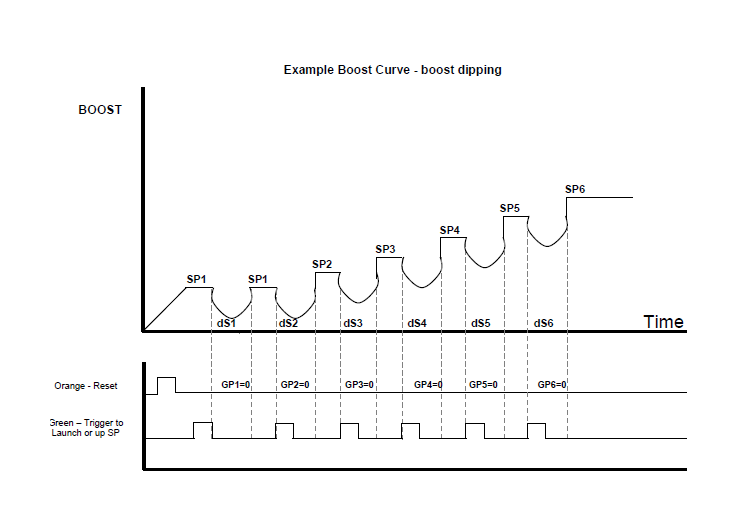

SSD (Sequential switching function D): Sequential switching function D is an advanced boost level switching function where you can configure a time delay to give either a drop in boost or a spike between switching boost levels. For example in a drag racing application you may want lower your boost during launch to maintain traction and spike your boost during gear changes to compensate for a drop in RPM.

EXAMPLE 1: BOOST DIPPING BETWEEN BOOST LEVEL SWITCHING

• Earthing the green wire will scroll up through set points starting at SP1 up to SP6 one at a time.

• Earthing the orange wire will reset and return to SP1 and dS1 (launch time delay)

• Activating SSD will display dS1-6 in their respective boost groups.

• These time intervals (dS1-6) can be used to give a dip in boost or spike in boost during the time delay.

• To create a dip in boost set the gate pressure to zero of the boost group that you are switching to. For example to dip the boost in the launch sequence set GP1 to zero as shown on the diagram below and define how long you want the boost to dip for in the time interval parameter dS1. To dip the boost when switching between boost levels eg between SP1 and SP2 set GP2=0 and dS2 equal to the amount of time you want the boost to dip for. The solenoid is in fact turned off during the time delay so the waste gate actuator is seeing manifold pressure. You will need to tune the time delay so that your boost does not drop too far during this time delay.

• dS1 and SP1 will be active after a reset by earthing the orange wire through a switch.

• The first time interval will start once the green wire has been earthed and un-earthed. If this switch is setup on a clutch mounted the launch time delay dS1 will start when the switch is opened again. On a clutch mounted switch this could be when clutch is released for launch.

• After the time delay associated with dS1 has elapsed, SP1 will continue to be active.

• SP2-6/dS2-6 will be triggered when the green wire is earthed through a switch. For example if the time delay is between gear changes the time will start when switch is closed e.g. on clutch mounted switch when clutch is depressed for the gear change.

• During the time delay the solenoid will be off hard (i.e. actuator seeing manifold pressure) if the gate pressure has been set to zero. Once the time delay has elapsed the boost level will switch to the subsequent set point boost level.

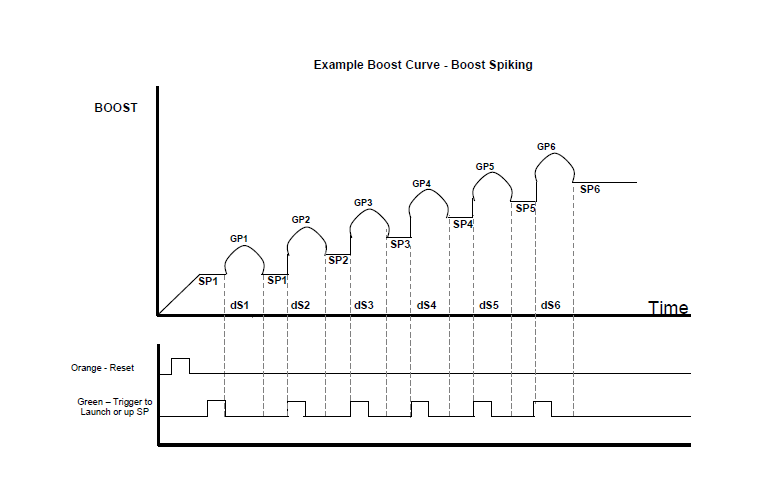

EXAMPLE 2: BOOST SPIKING BETWEEN BOOST LEVEL SWITCHING

• Earthing the green wire will scroll up through set points starting at SP1 up to SP6 one at a time.

• Earthing the orange wire will reset and return to SP1 and dS1 (launch time delay).

• To create a spike in boost during the time delay you must set the gate pressure for the relevant boost level higher than the boost level achieved with the set point. For example if you know that a SP2 value of 40 gives you a boost pressure of 14 psi you can spike your boost pressure to say 17 psi by setting GP2 = 17 psi.

• You must also set the time interval dS during which you want your boost spike.

• If your time interval (dS) expires before your gate pressure spike is reached the boost level will go to the SP boost level.

• If your gate pressure is reached before the time interval dS expires then the time interval will be cut short and the boost level will return to the boost level for the next set point.

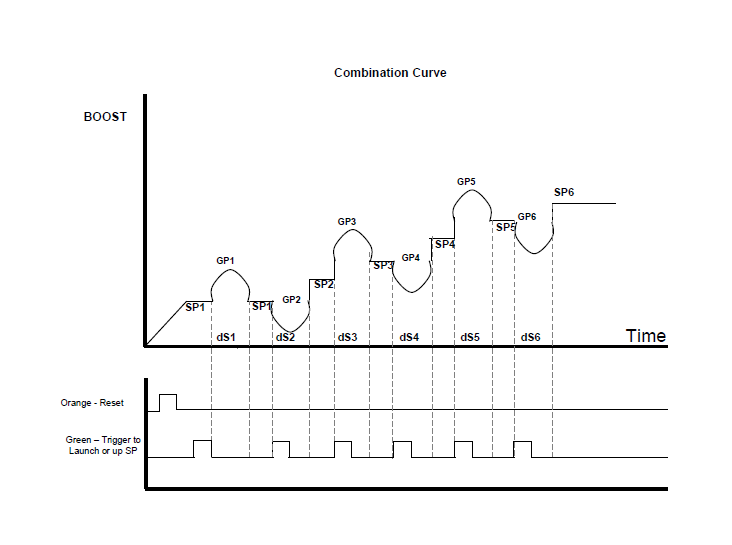

EXAMPLE 3: COMBINATION OF BOOST SPIKING & BOOST DIPPING BETWEEN BOOST LEVEL SWITCHING

- A combination of spikes and dips as shown below can be achieved through entering zero gate pressure where you want a dips and a gate pressure (the max of the spike) where you want a boost spike.

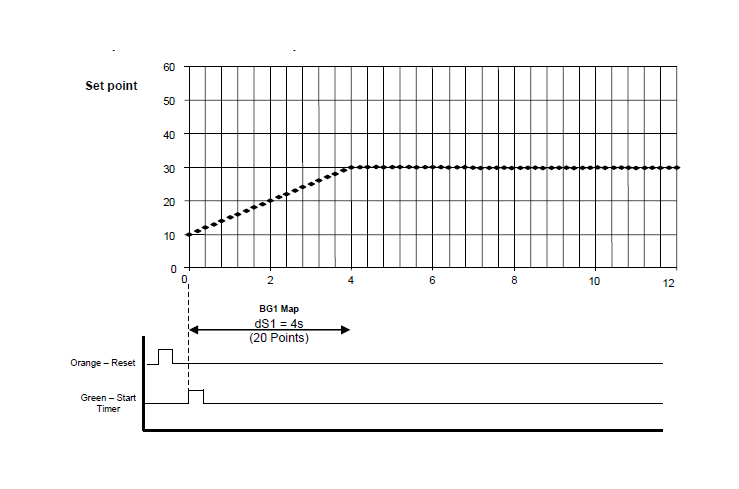

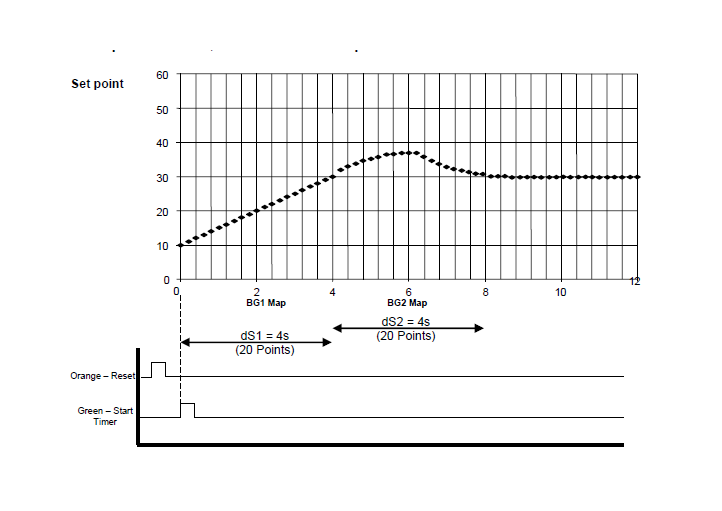

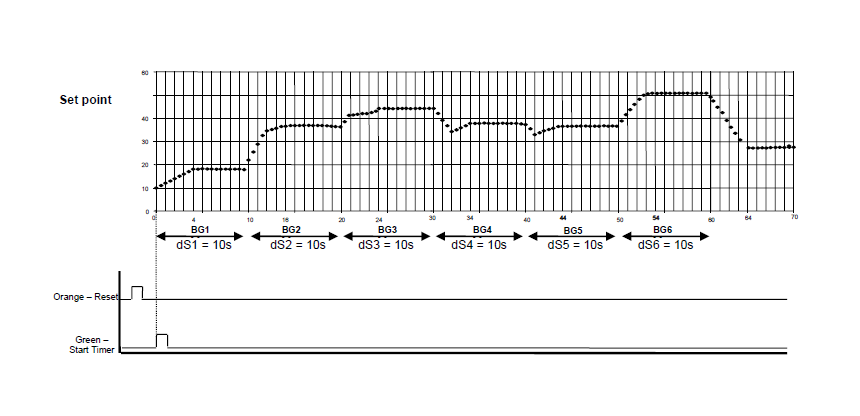

SSE (Sequential switching function E): Timed sequential switching function E allows the set-points to be mapped and switched during a predetermined time interval.

• dS1-6 is the amount of time you wish each boost group to be active for, up to a maximum of 99 seconds. dS can be entered in 0.1s increments – 6 seconds = 060

• Only the first 4 seconds of each boost group can be mapped and the last set point value that is mapped will continue to be active for remainder of the time delay (if set longer than 4 seconds).

• The first 4 seconds can be mapped in 0.2 second intervals which means you can have up to 20 mapped set point values within the first 4 seconds of the boost group.

• Entering a value in the SP parameter of the boost group will paste this value through all time increments.

• Gate pressure is not available with this function and will no longer be visible in the boost group.

• dS1 will refer to the amount of time BG1 is active before switching to BG2, dS2 to the amount of time BG2 is active before switching to BG3 and so on.

• This is a solely time based switching method and will not be dependant on switching except for a reset to SP1 (earthing the orange wire) and a GO (earthing the green wire) which will start the timer.

Example 1: dS1=4s with 4s map defined

Example 2: dS1=4s, dS2=4s with 8s map defined

Example 3: dS1-6=4s – Maximum 24s of full mapping

Example 4: Time delays as shown with mapping for first 4s then remainder of dS on last map point

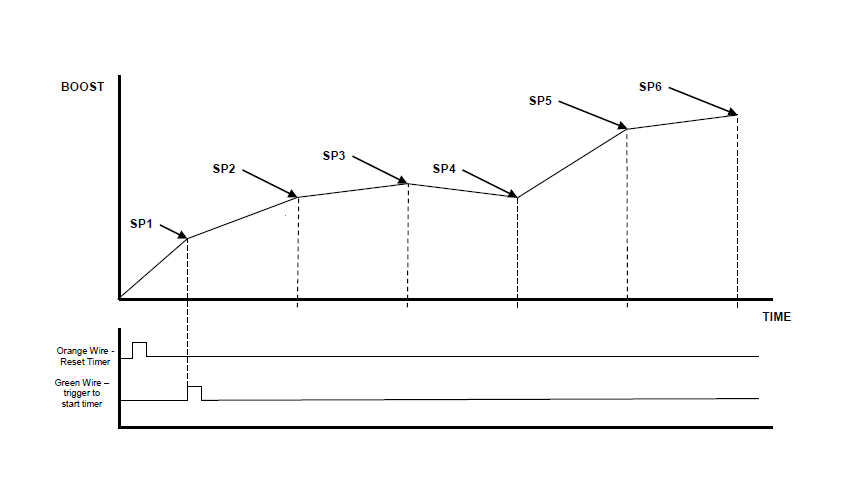

SSF (Sequential switching function F): Timed sequential switching function F allows the set point values to gradually increase over time. This switch logic could be applied in a drag racing situation where you want to gradually increase boost levels over a desired time interval within your elapsed time (ET). The Set point value will increase linearly between the user defined set point targets, e.g. If SP1 was 20 and SP2 was 50 and the delayed time was 5 seconds, when the timer is started, it would start at SP1 and over 5 seconds, gradually ramp up to SP2

• With SSF active dS1-dS6 will appear in each boost group.

• These time intervals can be entered as the amount of time you want each set point to be active before switching to the next set point.

• Time delays are in increments of 1/10th of a second, with the maximum allowable being 99 seconds.

• dS1 refers to the amount of time that it will take SP1 to gradually increase to SP2, dS2 refers to the amount of time that it will take SP2 to gradually increase to SP3 and so on.

• Earthing the orange wire with a switch will reset the timer and switch to SP1/BG1.

• Earthing the green wire will start the timer at SP1

• The same procedure will happen for all active set points (determined by the nSP parameter in the setup menu)

• Once the last time interval has ended the unit will continue to operate at the final set point.

• To skip a set point/boost group, set the dS parameter for that group to zero.

• This is a solely time based switching method and is not dependant on switching except for the reset to SP1 (earthing the orange wire) and a GO (earthing the green wire) which will start the timer.

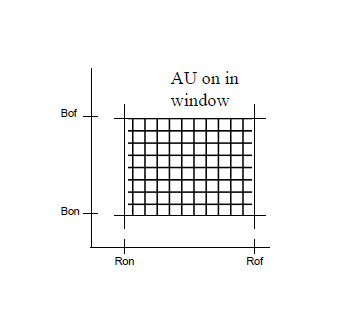

AU (Auxilary output)

The e-Boost2 has an auxiliary output function designed to control an auxiliary device once a certain boost pressure or RPM value is reached i.e. water spray, water injection, warning light or nitrous controller. This circuit can be used to control a resistor type automotive relay with a maximum current draw of 2 amps.

There are four options bOn, bOF, rOn and rOF. The boost setting on (bOn) and off (bOF) value will be entered in the units that are currently selected for display. Between the bOn and bOF values the auxiliary output circuit will be closed and therefore will switch the relay on.

The RPM setting on (rOn), and off (rOF) are entered as RPM x 100 e.g. if 5000 RPM is the desired setting the user will input 050. Between the rOn and rOF values the auxiliary output circuit will be closed.

If the bOF or rOF is set to zero there will be no off and the circuit will remain closed until boost or RPM drops below the rOn or bOn value. If using a boost setting only to switch the relay the RPM parameter values should be set to zero to turn off or vice versa.

If using the auxiliary circuit as a nitrous controller, you can enter all four user definable parameters bOn, bOF, rOn, and rOF. The auxiliary circuit will be closed when boost and RPM fall with the window created by these four parameters. That is when boost pressure is between bOn and bOF AND when RPM is between rOn and rOF.

LE1/LE2 Shift/warning lights (LED 1/LED 2)

The e-boost2 has 2 LED outputs that can be used as shift lights or boost level warning lights. These LED outputs can be configured to turn on and off at any boost pressure or engine RPM. Within the LE1/LE2 menus there are 5 parameters bOn (Boost pressure on), bOF (Boost pressure off), rOn (RPM on), rOF (RPM off) and rFL (RPM flashing).

Between the on and off values the LED will be illuminated. If the bOF or rOF is set to zero there will be no off and the LED will remain illuminated until boost or RPM drops below the bOn or rOn value.

You can also set a flashing warning RPM value rFL (RPM flashing) at which the led will flash until rOn is reached. Once rOn is reached the LED will turn on solid. rFL must be set to an RPM less than rOn. Setting rFL to zero will disable the flashing output.

Boost values are entered in the units currently selected for boost pressure display. RPM values are entered as RPM x 100 e.g. if 5000 RPM is the desired setting then input 050. If using a boost setting, RPM values should be set to zero to turn them off. If using a RPM setting the boost parameters should be set to zero to turn them off.

The four wires associated with these two outputs are wired into a 4 pin plug located beside the main harness 8 pin plug. A single or double LED accessory kit is available from Turbosmart that plugs directly into the eboost2 LED output with no additional wiring necessary.

If rOn, rOF, bOn and bOF values are entered on 1 LED, the LED will illuminate only when the RPM set points have been reached. The boost values are redundant.

AL (Audible alarm)

The e-Boost2 has an audible alarm function that sounds the internal buzzer once a certain boost pressure or RPM is achieved. The audible alarm is factory set to 15 psi (1 bar or 100 kPa) but can be programmed for any boost pressure or RPM. Within the AL parameter there are four options bOn, bOF, rOn and rOF.

The boost setting on (bOn) and off (bOF) values are entered in the units that are currently selected for display. Between the bOn and bOF values the buzzer will be activated.

The RPM setting on (rOn), and off (rOF) are entered as RPM x 100 e.g. if 5000 RPM is the desired setting then input 050. Between the rOn and rOF values the buzzer circuit will be closed.

If the bOF or rOF is set to zero there will be no off and the buzzer circuit will remain closed until boost or RPM drops below the rOn or bOn value. If using a boost setting RPM values should be set to zero to turn off or visa versa. Setting these parameters to zero will disable them as parameters.

If rOn, rOF, bOn and bOF values are entered, the alarm will sound when either the boost or the RPM value is reached and will turn off when the boost or RPM drops below the set point or both values reach there respective bOF and rOF values.

dS (Delayed switching)

This function is for use with set point switch logics ISP/ESP/SSA/SSB and is designed to create a delay between set point switching and activation. The time delay will be between when a subsequent set point is switched and when it actually changes i.e. the current set point will continue functioning until the time delay has elapsed. dS1 in boost group 1 applies to the time delay when switching to SP1, dS2 in boost group 2 applies to the time delay when switching to SP2 and so on. To use time delay between set point switching and activation, dS must be ON. In the SETUP Parameter Menu you can activate or de-activate this function. If this function is de-activated all menus relating to the time delay are hidden from the Boost Menu i.e. dS1 – dS6 in respective boost group. Once dS is activated in the SETUP Parameter Menu, you can enter the delay time in the Boost Group.

Note: Activating SSC/SSD and SSE also brings up the dS parameter in the boost group. Refer to section 5.6 for further details on the set point switching logic and what this parameter applies to.

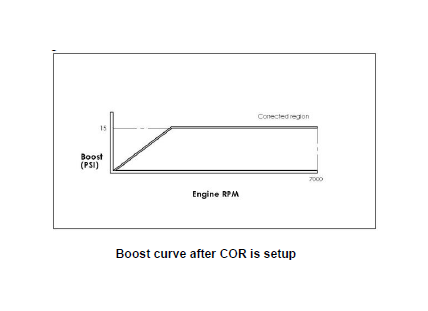

COr (Boost correction)

This function is use to reduce or eliminate boost drop off at high RPM. Switching this function on will display the boost correction menu in the boost group menu. This function is best performed on a chassis dyno where the graph of the boost curve can be displayed and accurately interpreted.

The boost correction function requires 3 parameters to work; the START RPM, the END RPM and the correction factor.

START RPM (RP1): This is the engine RPM at which boost begins to drop off.

END RPM (RP2): This is the engine RPM at which you want to turn off the boost correction function, normally set at redline.

Correction factor (FAC): The percentage at which boost is dropping off between the START and END RPM.

Example:

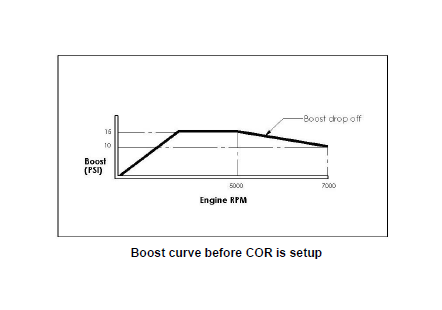

The following boost curve shows that between 5000 and 7000 RPM, the boost drops off from 15 PSI to 10 PSI.

To reduce or eliminate this boost drop off, you need to input the following values:

RP1 = 050 (5000 RPM)

RP2 = 070 (7000 RPM)

FAC = 100 - [(10 ÷ 15) X 100] = 33

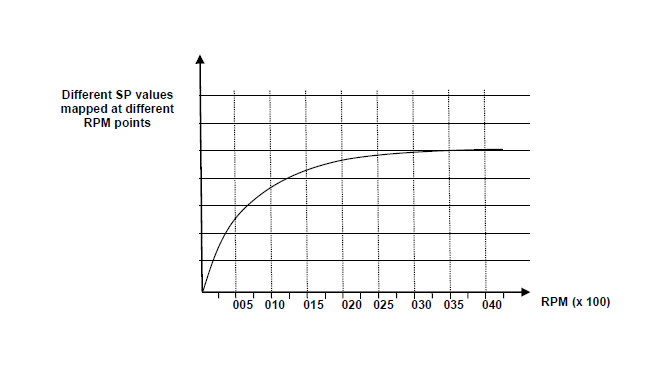

rSP (RPM based set point mapping)

This function allows you to map your boost curve against RPM. You can enter set point (SP) values against RPM values so you can tailor you boost curve. The RPM values are mapped in increments of 500 or 1000 RPM depending of the maximum RPM selected. RPM is displayed on the readout as RPM x100 eg 005 (5 x 100RPM) is 500 RPM.

At each increment the desired offset which in turn gives you a boost pressure can be defined. When this function is turned on the RPM points 005, 010, 015, 020 through to 190, 195, 200 will appear in each boost group. Entering a value in the Boost Set Point (SP) parameter of the boost group will paste that value through all RPM points. This gives a starting point to adjust from.

When activating this function 3 options are available off, 10 and 20. Selecting 100 will give a max RPM of 10000 with 500 RPM increments and selecting 200 will give a max RPM of 20000 and 1000 RPM increments. You could use this function to smooth out dips in your normal boost curve at certain RPM by enter higher set point values for these RPM.

Note this function is available for use with ISP, ESP and SSA-SSC. This function is cannot be turned on if SSD or SSE is on and if SSD or SSE is activated with rSP already then rSP will be turned off. RSP also cannot be used at the same time as COR (turning rSP on with COR already on will turn off COR).Gate pressure can be used with this function

Pin (Security Pin number)

The user or workshop can set a 3 digit password that will lock the boost menu, obS, SL, rSP, COR, dS, nSP, and CYL parameters for editing. The default code is 000 set from the factory. If the code has not been changed then the unit will be fully accessible and everything will be available for editing. As soon a different value is entered under the PIn parameter in the setup menu this will be the new password.

Once a password has been set under PIN in the setup menu pressing mode and down to access the boost menu will bring up a 3 digit prompt (triple zeros) where a PIN must be entered correctly to enter the boost group and unlock the unit.

Once a password has been configured the obS, CYL, SL, rSP, COR, dS, nSP, in the setup menu will be masked and not available for editing. To unmask these parameters go to the PIn parameter and enter the current password to unlock the setup parameters for editing. Alternatively enter the correct PIN in the boost group prompt and the entire unit will be unlocked until the PIN is re-entered in the PIN parameter to re-lock the unit.

Applying the factory reset will reset the code and reset all stored values to the factory defaults. This function enables workshops or tuners to lock their setup against tampering. Returning the PIN to 000 will de-activate the password protection.

Ser (Serial Number)

The serial number of your e-Boost2 unit can be displayed on the screen. This can be useful for technical support. The number will scroll through 6 numbers.

Sol (Solenoid Cycle)

This function is used to check whether the solenoid is properly connected to the head unit. Selecting this function will cause the solenoid to cycle (click) 4 times.

ZEr (Gauge Zero)

The e-Boost2 is factory calibrated to read zero at standard atmospheric pressure and temperature. The e-Boost2 is altitude compensated however a large change in temperature can cause the display to read slightly above or below zero even when there is zero pressure applied to the e-Boost2. This function allows you to re-zero the e-Boost2 display. IMPORTANT! Before using the zero function ensure there is no boost or vacuum pressure or trapped pressure in the e-boost hose before re-calibration.

rES (Reset)

This function performs a factory reset and returns all the settings back to factory default.

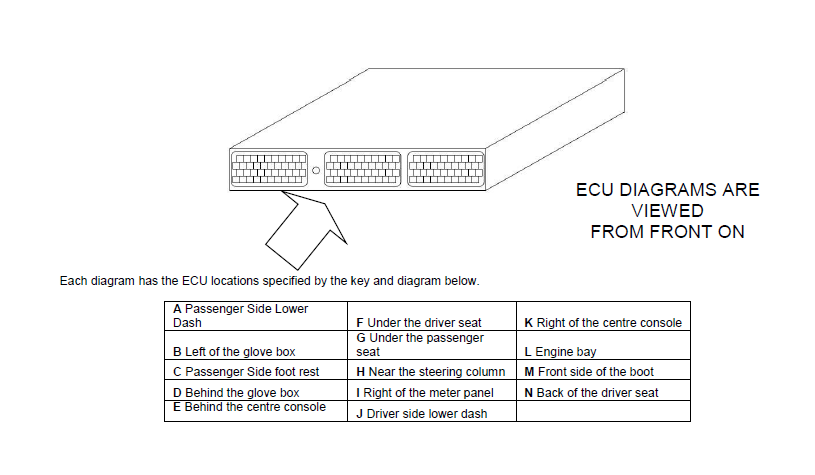

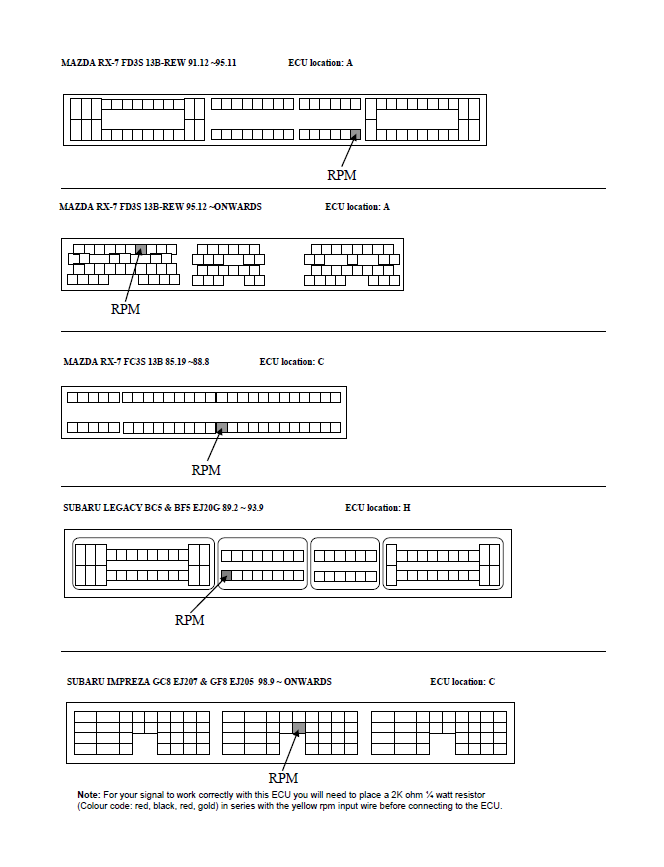

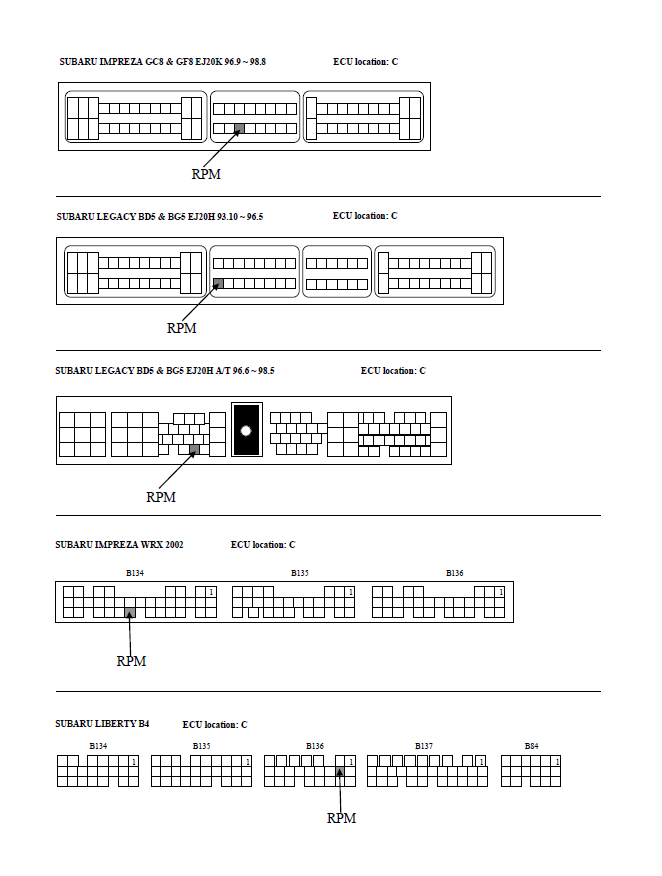

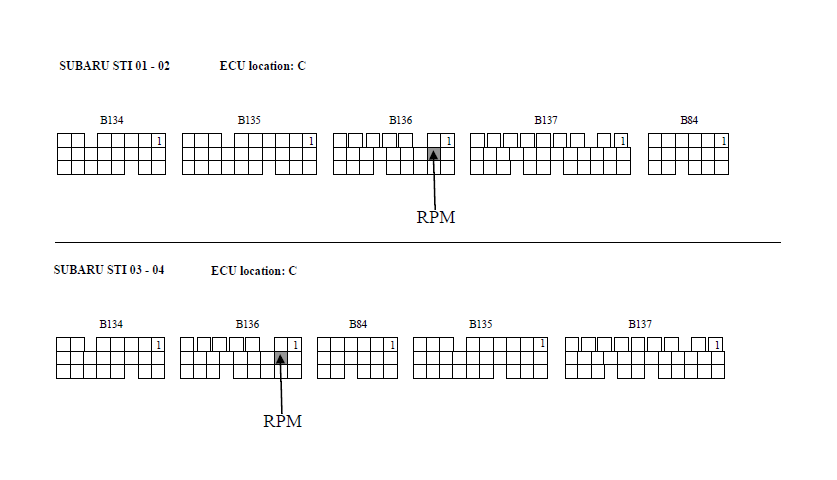

VEHICLE WIRING DIAGRAMS

Following are vehicle specific ECU wiring diagrams for connecting the yellow RPM signal wire. Turbosmart recommends consulting an appropriately qualified technician for this installation. Be sure to count the number of pins and securely connect the yellow RPM wire to the appropriate ECU wire. Be sure to cover any exposed connections with electrical tape. Included with the kit are some resistors that can be added in line with the RPM signal to the head unit from the instrument cluster if the tachometer stops displaying RPM but the Eboost2 does display RPM. If 1 resistor does not fix the issue, add another resistor inline.

TROUBLESHOOTING

The following points should be checked if you find that your engine is over-boosting, under-boosting or the boost pressure is fluctuating erratically. Please note the following checks will cure 99% of problems experienced when fitting a Turbosmart e-Boost2.

- Check that the e-Boost solenoid is installed correctly.

- Ensure the factory boost control solenoid is not connected in the hose between the pressure source and the waste gate actuator

- Ensure the length of the waste gate actuator rod has not been modified, refer to the manufactures specifications

- Check to see if the e-Boost solenoid is not blocked or contaminated with dirt, oil build up or debris

- Check the joining hoses for splits, cracks or loose connections and ensure they are not blocked, kinked or restricted, particularly if the existing hose was reused

- Pressure test the waste gate actuator for leakage, the diaphragm or housing may be cracked or split

- Ensure the smooth and free operation of the waste gate arm in the turbo exhaust housing.

- Check that the hose between the e-Boost and the inlet manifold is not obstructed, broken or kinked.

- Check that the OBS is set higher than the boost pressure you are aiming for.

- Check the Blow-off Valve for leakage, some are used as over-boost valves

- Gate pressure maybe set too close to your actual boost pressure

- Ensure correct sensitivity setting.

- Use the Solenoid check function to determine whether the solenoid is electrically connected to the head unit.