Guaranteed Free Delivery by 12/24! available on most items - Details

How to Install Vortech V-3 Si Supercharger - Black on your Mustang

Installation Time

1 days

Tools Required

- Factory repair manual

- 3/8" socket and drive set: SAE & metric

- 1/2" socket and drive set: SAE & metric

- Adjustable wrench

- Open end wrenches: metric

- TORX T-20 driver

- Utility knife

- 3/8" NPT tap, center punch

- 5/8" tapered punch

- heavy grease

- 8 quarts manufacturer-specified engine oil

- oil filter

- oil filter wrench

Shop Parts in this Guide

Ford 5.0L

Mustang GT

Supercharger System

Installation Instructions

2015 Model Year*

1. BASIC COMPONENT REMOVAL

A. Remove eight (8) plastic fasteners securing the black plastic cover above the grille and radiator. Pop the center section of each fastener upward and then the larger part of the fastener will loosen. Remove the cover and set aside for later re-installation. (See Fig. 1-a)

B. Remove the (6) 8mm-headed fasteners securing the front bumper cover to the upper radiator support. Set aside for later re-installation. (See Fig. 1-b)

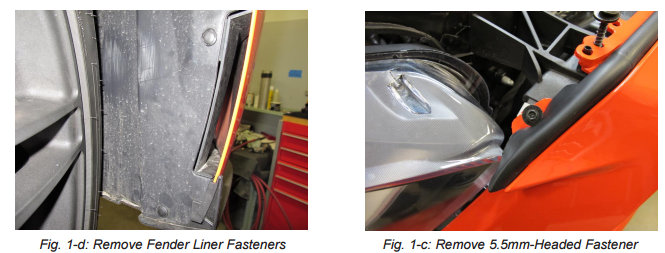

C. There are (2) 5.5mm-headed fasteners (one on each side) hidden underneath the weather stripping on the top of the bumper cover near the headlights. Remove these fasteners & set aside for later re-installation. (See Fig. 1-c)

D. Remove the 4 plastic fasteners securing the fender liners to the fenders & front undertray. Do this for both sides. (See Fig. 1-d)

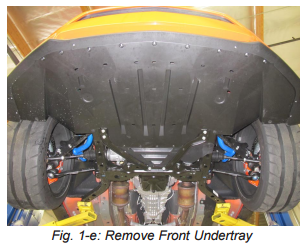

E. Remove the (19) 7mm-headed fasteners & (2) plastic fasteners securing the front undertray to the bumper cover & K-member. (See Fig. 1-e)

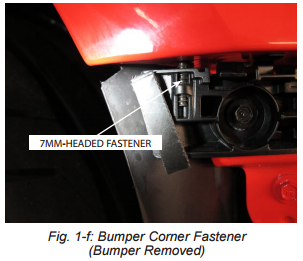

F. There are (2) 7mm-headed fasteners (one per side) securing the corners of the front bumper cover to the fender. You will need to pull back the fender liner to access this fasteners & remove. (See Fig. 1-f)

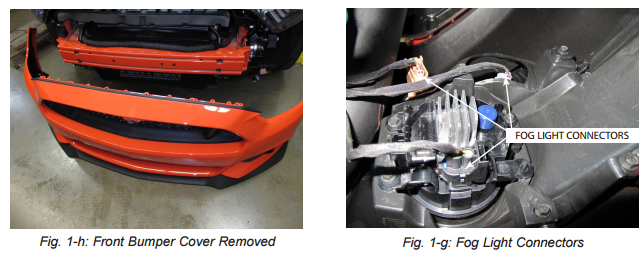

G. With the front undertray removed, reach up behind the front bumper cover & unplug the fog light connectors. Do this for both sides. (See Fig. 1-g)

H. Pull the corners of the front bumper cover away from the fender. Carefully remove the front bumper cover from the vehicle, exposing the bumper support. (See Fig. 1-h)

I. You will notice a wire harness running along the back side of the bumper support secured by (3) gray clips. Free the harness from the bumper support. (See Fig. 1-i)

J. Release the gray clips from the wire harness & set aside. these will not be reused. (See Fig. 1-j)

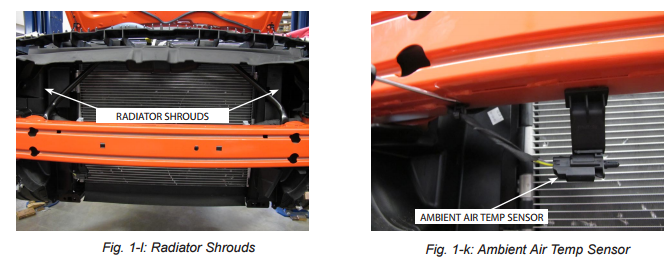

K. Unplug the clip from the ambient air temp sensor, then release the harness from the bumper support. Also, remove the sensor & set aside for later re-installation.

L. Remove the both radiator shrouds. These will be trimmed in a later step. NOTE: If your vehicle is equipped with the optional front braces, they will need to be removed. (See Fig. 1-l)

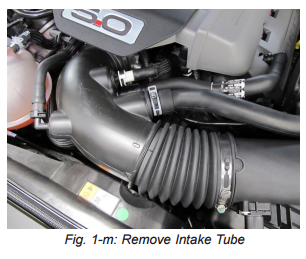

M. Remove the engine cover, disconnect the hoses going to the intake tube & proceed to remove the intake tube from the vehicle It will not be reused. (See Fig. 1-m)

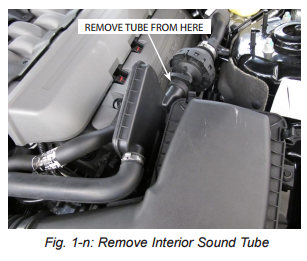

N. Remove the interior sound tube by pulling it towards the front of the vehicle. (See Fig. 1-n)

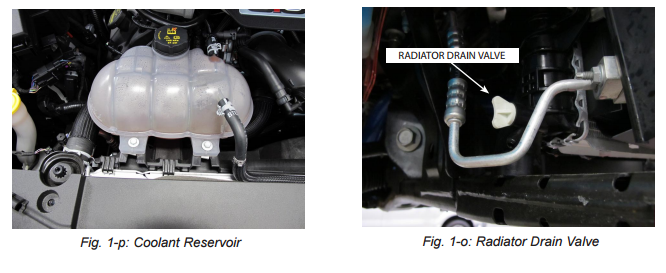

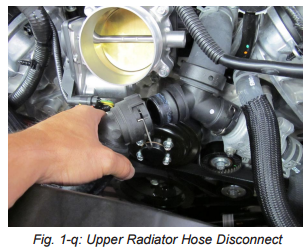

O. Remove the pressure cap from the engine coolant reservoir near the passenger side front of the engine compartment. Locate the engine coolant drain valve at the bottom passenger side corner of the radiator. Open the valve and drain the coolant into a clean container for later reuse. Drain enough to empty the reservoir and below the level of the upper radiator hose. (See Fig. 1-o)

P. Unclamp and disconnect the two small hoses from the upper portion of the coolant reservoir & disconnect the larger hose from the bottom of the coolant reservoir. Be prepared to catch any spillage. Remove the two (2) 10mm-headed fasteners securing the coolant reservoir. Remove the reservoir and set it aside. It will not be reused (See Fig. 1-p)

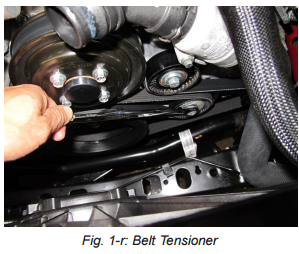

Q. Release the upper radiator hose clamp connection to the radiator. Release the quick release upper radiator hose connection to the thermostat housing by pulling the spring clip back and sliding the hose fitting off. Remove the upper radiator hose and set it aside for later modification. Remove the coolant hose to the right of the "Y" fitting, above the thermostat housing & set it aside. It will not be reused (See Fig. 1-q)

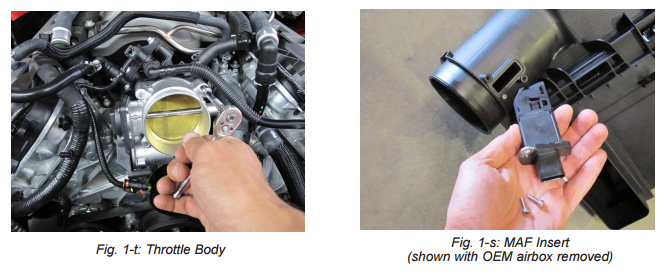

R. Use a 15mm wrench to rotate the belt tensioner counter-clockwise to release tension from the outer 6-rib accessory drive belt. Remove the belt and set it aside as it will not be reused. (See Fig. 1-r)

S. Remove the two (2) TORX T-20 fasteners securing the MAF insert into the OEM airbox. Remove the MAF insert and set aside for later use. (See Fig. 1-s)

T. Unplug the electrical connector from the throttle body by sliding the red clip outward and depressing the tab. Remove the four (4) 10mm-headed screws securing the throttle body to the intake manifold. These fasteners will not be reused. Remove the throttle body and set it aside for later reinstallation, ensuring that the sealing gasket remains in the intake manifold. (See Fig. 1-t)

2. MISCELLANEOUS PREPARATION

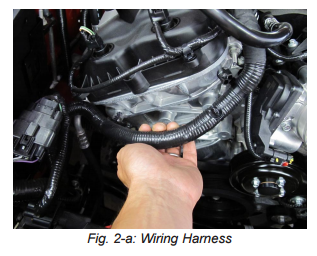

A. Free the large wiring harness from the two (2) mounting locations on the engine front cover forward of the passenger side cylinder head. Use extra care when disengaging the lower clip from the threaded hole in the engine cover as this threaded hole will be used in a later step. If part of the clip breaks off in the threaded hole, carefully extract it without damaging the threads. Route the harness higher up along the passenger side valve cover. (See Fig. 2-a)

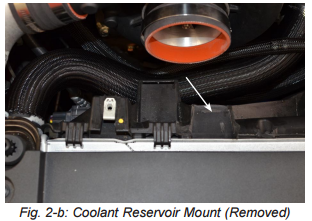

B. Cut off the coolant reservoir mount closest to the drivers side of the vehicle. This is to make room for the new intake tube. You may need to make further adjustments when you install the intake tube. (See Fig. 2-b)

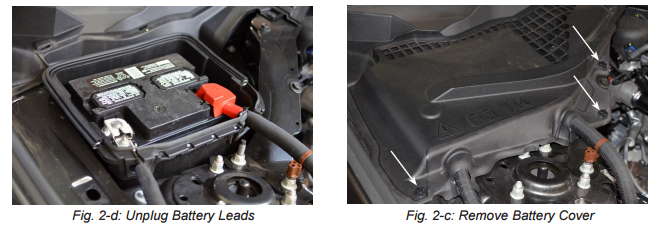

C. Remove the battery cover by removing the (3) plastic fasteners & pulling forward. (See Fig. 2-c)

D. Unplug the battery leads. (See Fig. 2-d)

E. Remove the coil covers from the cylinder heads. Remove the ignition coils and spark plugs. Re-gap the spark plugs to .032", re-install and torque to 9 ft-lbs. Reinstall the coils and coil covers.

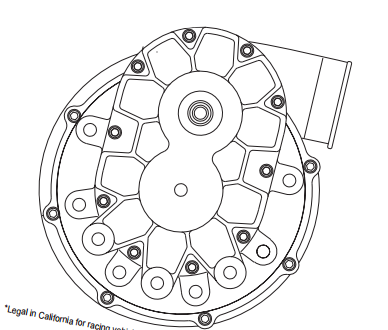

3. SUPERCHARGER ASSEMBLY PREPARATION AND INSTALLATION

NOTES:

1. Refer to Figure 3.1 near the end of this section for the size and position of all spacers.

2. Use blue Loctite (thread locker) on the threads of each screw prior to final tightening of the assembly.

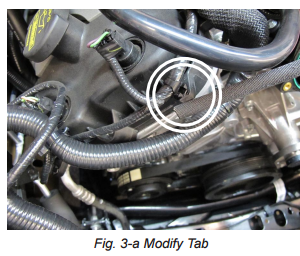

A. Using a coarse file or similar tool, remove approximately 1/8” from the front edge of the passenger side valve cover tab. See Fig. 3-a. This will ensure proper supercharger-to-valve cover clearance during installation.

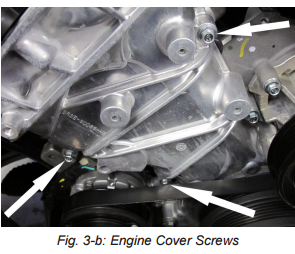

B. Remove the following three (3) 10mm-headed screws securing the engine front cover on the passenger side: (See Fig. 3-b)

a. The uppermost screw

b. The screw just above the A/C compressor

c. The screw between the A/C compressor and the crankshaft

3. SUPERCHARGER ASSEMBLY PREPARATION AND INSTALLATION

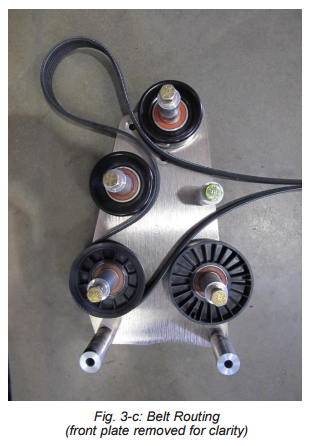

C. Inspect the supercharger mounting plate/idler pulley assembly and familiarize yourself with its components and configuration. The new belt should be routed so that the ribbed side engages the ribbed idler pulley and the smooth side rides on the other pulleys. Note the multiple mounting locations of the ribbed idler, used to compensate for different supercharger pulley sizes and belt lengths. All four (4) idler mounting bolts should be left slightly loose during installation to facilitate alignment. (See Fig. 3.1 and Fig. 3.2 Belt Routing Diagram later in this section)

D. Thread the two (2) included M8 x 200mm studs into the lower two engine cover fastener holes, in the locations of the previously-removed fasteners (one just above the A/C compressor and one between the A/C compressor and the crankshaft). Use a small amount of blue thread lock on the threads. Leave approximately 6" of stud exposed.

E. Slide a .875” x 2.058” spacer over the stud above the A/C compressor. See Fig. 3.1 near the end of this section for this and all other mounting bracket spacer and fastener locations.

F. Slide a .875” x 2.146” spacer over the stud between the A/C compressor and the crankshaft.

G. With the thinner steel plate closer to the engine, begin to slide the mounting bracket assembly over the studs. Place a .875” x 2.730” (.323 I.D.) spacer over each stud, sandwiched between the two mounting plates.

H. Place a 5/16” flat washer over the open end of each stud and secure with an 8mm flange head nut. Adjust stud exposed length as needed so 1-2 threads protrude beyond the nut. Do not tighten at this time.

I. Locate the .875” x 1.928” spacer and M8 x 80mm hex head screw. Place a 5/16” flat washer on the screw and pass it through the outer (3/8" thick) plate and .875” x 1.928” spacer into the threaded boss on the engine cover in the location furthest toward the passenger side. Do not tighten at this time.

J. Locate the remaining .875” x 2.058” spacer and M8 x 100mm button head screw. Pass the screw through the inner (1/4" thick) plate (with no washer) and .875” x 2.058” spacer into the uppermost engine cover hole from which an OEM screw was previously removed (2nd hole from the top overall). Do not tighten at this time.

k. Tighten the four (4) idler pulley mounting bolts. Ensure that the second-highest bolt has the thin washer (the others have standard-thickness washers).

l. Confirm that the four (4) screws and two (2) studs securing the supercharger assembly to the engine are properly aligned. Tighten them in progressive steps in an alternating sequence.

M. Engine Oil Fed Units Only: Locate the included length of black braided 1/2" oil drain hose. Remove the shipping cap from the 1/2" barbed oil drain fitting on the bottom of the supercharger and attach the drain hose with the included #8 worm gear clamp.

N. Place the supercharger into the cradle of the outer mounting plate, aligning the five (5) mounting holes, with the pulley toward the engine and the discharge pointing straight down. Secure the supercharger to the plate with five (5) 3/8-16 x 1.25 hex head screws with washers. Route the braided drain hose (if equipped) directly downward, away from moving parts and sharp edges, and secure.

O. Align the 6-rib drive belt according to the diagram shown at the end of this section. The belt routing is almost identical to the OEM routing with the exception of the portion that passes between the water pump pulley and crankshaft pulley to drive the supercharger. Ensure that the belt routes smoothly over the supercharger pulley and all of the new idler pulleys as well as the OEM engine accessories.

P. Use a 15mm wrench to rotate the OEM belt tensioner counter-clockwise and install the belt. Depending on pulley size, it may be necessary to adjust the location of the ribbed supercharger idler pulley to achieve proper belt tension. Ensure that the belt wraps smoothly around each of the pulleys and that all ribbed pulleys are properly engaging the belt's ribs.

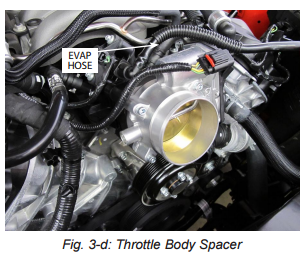

Q. Locate the supplied 1.25” black anodized aluminum throttle body spacer. Install the included large O-ring into the groove in the spacer -- this O-ring seals against the throttle body, and the smooth side of the spacer seals against the OEM O-ring in the intake manifold. Reinstall the throttle body, rotated 180° from its original orientation (upside-down), using this spacer, the four (4) included M6 x 80mm socket head cap screws, and four (4) included 6mm washers. Ensure that both O-ring seals stay in place. The OEM evaporative emissions tube connecting to the solenoid on the intake manifold just behind the throttle body will have to be slightly bent. (See Fig. 3-d)

R. Carefully snip the strip of tape securing the throttle body electrical harness to the connector housing. Reconnect the connector to the throttle body.

S. Route the large wiring harness near the passenger side valve cover, throttle body electrical harness, and any other items away from moving parts and sharp edges and secure.

4. PCV SYSTEM MODIFICATION

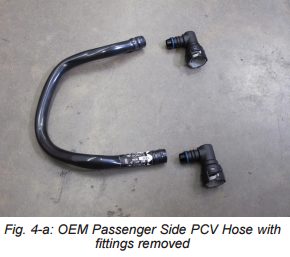

A. Modify and reinstall the passenger side PCV hose as follows:

a. the plastic tube until it can be split away from the barbed fittings inside. Take care not to damage the fittings. (See Fig. 4-a)

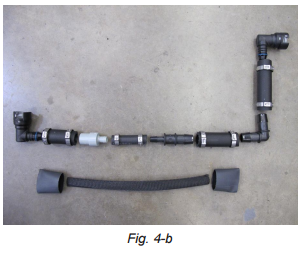

b. Locate the supplied 90° PCV hose assembly. b. (See Fig. 4-b)

Slide a #25.6 stepless clamp over each open c. end of the 90° PCV hose assembly and insert one of the previously-removed OEM 90° quick-release fittings into each open end. Do not secure the clamps at this time.

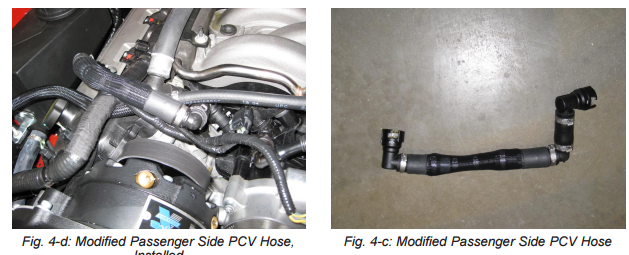

c. Orient the hoses and fittings as shown, test fit d. to the engine to confirm end fitting clocking for best fit, and secure the clamps. (See Fig. 4-c)

d. Install the assembly as shown with the end e. closest to the 90° plastic elbow connecting to the intake manifold. Secure as needed for clearance to the supercharger pulley. (See Fig. 4-d)

5. CHARGE AIR COOLER (CAC) & DISCHARGE TUBE INSTALLATION

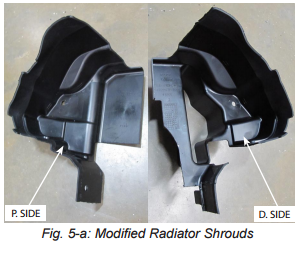

A. Prior to installing the cooler, the radiator shrouds will need to be modified. (See Fig. 5-a)

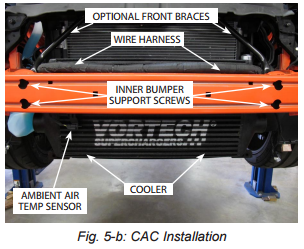

B. Back out the 4 inner-most screws of the bumper support, leaving about 1/2" of the screw protruding from the back side. Vehicles equipped with the Ford Performance Pack will need to remove the 4 nuts securing the brace to the back side of the bumper support prior to backing out the screws. Raise the cooler into position, making sure to align the cooler brackets to the 4 screws previously backed out. Once aligned, begin to thread the screws through the cooler brackets. Route the wire harness along the top side of the bumper support. Attach the ambient air temp sensor back to its factory location & plug in the electrical connector.(See Fig. 5-b)

C. If your vehicle is not equipped with the optional front braces, proceed to install the cooler against then bumper support, then secure with the provided M8 x 1.25 flanged nut & 5/16 washers.

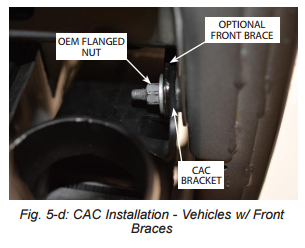

D. Vehicles equipped with the optional front braces, reuse the factory hardware, making sure the cooler bracket is sandwiched between the lower brace mounts & bumper support. (See Fig. 5-d)

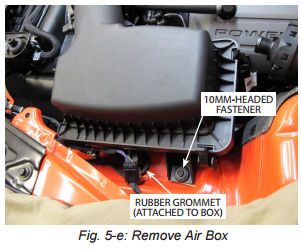

E. Remove the 10mm-headed fastener securing the air box, then remove the air box from the vehicle. (See Fig. 5-e)

F. Remove the snorkel from the air box & set aside. It will not be reused.

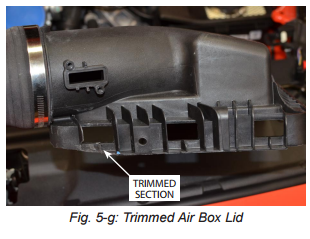

G. Trimming of the air box lid may be required to clear the discharge tube. Trim as necessary. (See Fig. 5-g)

NOTE: Leave all hose clamps loose until all silicone couplers & discharge tubes are free & clear of any obstructions. Hose clamps will be tightened in Step O.

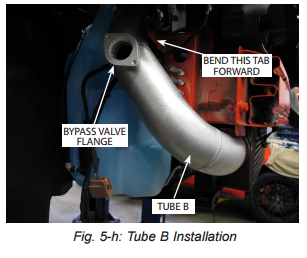

H. Install a straight 3" silicone sleeve & two #48 hose clamps to the passenger side of the cooler. Install a 3" silicone bump sleeve & two #48 hose clamps to the end of Tube B with the smaller bend. Slide the open end of Tube B into the silicone coupler on the cooler. For proper clearance between the body of the vehicle & the windshield washer reservoir, you will need to bend the steel tab, closest to the bypass valve flange, towards the front of the vehicle. (See Fig. 5-h)

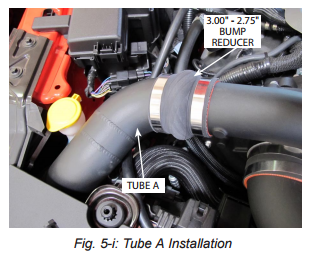

I. Install the 3.00"-2.75" silicone bump reducer sleeve to the volute. The volute end of the sleeve uses a #44 hose clamp, while the tube end uses a #48 hose clamp. Install Tube A & clock it accordingly. (See Fig. 5-i)

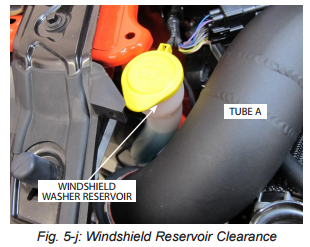

J. Make sure Tube A is clocked in a manner to clear the windshield washer reservoir. (See Fig. 5-j)

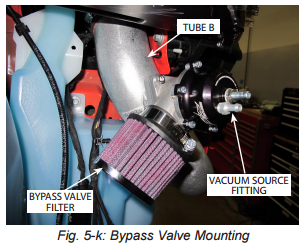

K. With tubes A & B in place, attach the bypass valve with the supplied hardware & gasket to the bypass valve flange on Tube B. Make sure that the opening of the bypass valve is facing towards the back of the vehicle. Once secured, attach the supplied 1" filter to the bypass valve & tighten the supplied hose clamp. (See Fig. 5-k)

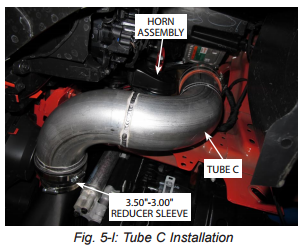

L. Install the 3.50"-3.0" reducer sleeve to the driver side of the cooler. Secure the cooler end of the reducer sleeve with a #48 hose clamp. Locate Tube C, which has two 90° bends, and slide one end of the tube into the silicone sleeve on the cooler & secure with a #52 hose clamp. Install a 3.5" silicone sleeve & two #52 hose clamps onto the open end of the Tube C. (See Fig. 5-l)

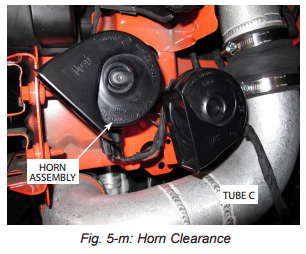

M. Make sure that Tube C is clear of the horn. You may need to relocate the horn wiring harness to keep it from resting against Tube C. (See Fig. 5-m)

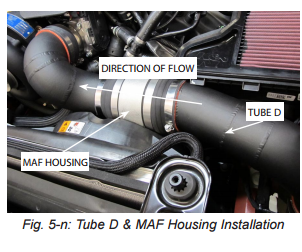

N. Locate Tube D & insert the one end of the tube into the silicone sleeve previously attached on Tube C. Attach the supplied 4.00"-3.50" silicone reducer sleeve to the other end of Tube D, then install the MAF housing. Be sure to have the "FLOW" arrow on the MAF flange facing towards the throttle body. (2) #52 hose clamps. (See Fig. 5-n)

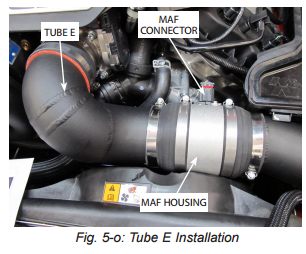

O. Attach Tube E to the throttle body using the supplied silicone reducer sleeve & clamps, then attach it to the MAF housing using the supplied 4.00"-3.50" silicone reducer sleeve. Once in place, insert the MAF sensor into the flange & secure with the provided hardware. Connect the MAF plug to the sensor. Verify that all tubes are free of any obstructions then proceed to tighten all of the hose clamps. (See Fig. 5-o)

6. FUEL INJECTOR REPLACEMENT

A. Disconnect the fuel feed line from the fitting near the driver side fuel rail. CAUTION: The fuel line may be pressurized. Take care to avoid spray and spills.

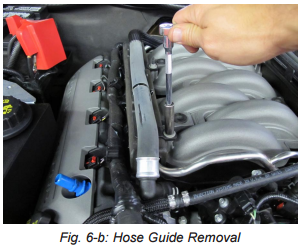

B. Remove the four (4) 10mm hex nuts securing the plastic heater hose guides and set the guides aside for later reinstallation. (See Fig. 6-b)

C. Reposition the vacuum tube assembly mounted under the driver side heater hose guide to facilitate fuel rail removal.

D. Remove the foam insulation from each fuel rail (2 pieces total).

E. Unplug each of the eight (8) fuel injector electrical connectors.

F. Remove the four (4) 10mm-headed screws securing the fuel rails to the intake manifold (2 per side)

G. Lift the fuel rails (with injectors attached) up and away from the engine, taking care not to spill fuel from the feed fitting. Drain the fuel from the rails.

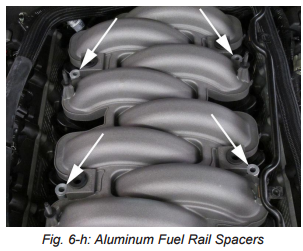

H. Locate the four (4) OEM aluminum fuel rail spacers lightly pressed into the intake manifold and pull them free. (See Fig. 6-h)

I. Locate the supplied shorter fuel rail spacers and insert them into the intake manifold in place of the OEM spacers.

J. Note the orientation of the OEM injectors in the fuel rails. Disengage the retaining clips and remove the OEM injectors.

K. Install the supplied high-flow injectors into the fuel rails in the same orientation as the OEM injectors and secure in the original fashion with the OEM retaining clips. (See Fig. 6-k)

L. Install the rail/injector assembly into the intake manifold.

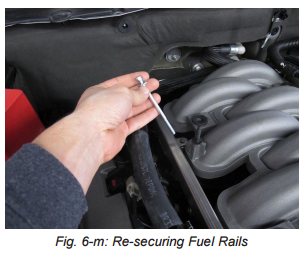

M. Secure the fuel rails with the four (4) included M10 x 90mm socket head cap screws with washers. (See Fig. 6-m)

N. Connect the fuel injector electrical connectors to each of the eight (8) injectors.

O. Place the foam insulation back over each fuel rail.

P. Place the vacuum tube assembly back into position on the studs near the driver side fuel rail.

Q. Reinstall the plastic heater hose guides and secure with the OEM 10mm hex nuts. Route the heater hoses over them in the OEM fashion.

R. Reconnect the fuel feed line to the fitting on the fuel rail assembly. Make sure it is securely connected in the OEM fashion.

7. ENGINE COOLING SYSTEM MODIFICATION

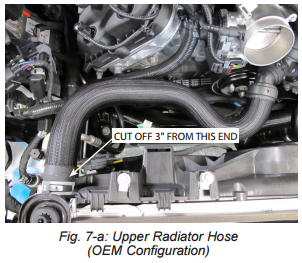

A. Locate the previously-removed OEM upper radiator hose. Remove the factory spring clamp & set aside. Cut off 3" from the end of the hose. (See Fig. 7-a)

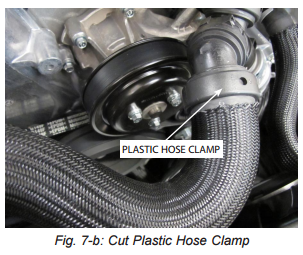

B. Cut away the OEM plastic hose clamp on the quick-release end of the radiator hose, taking care not to damage the hose. Separate the hose from the quick-release fitting. (See Fig. 7-b)

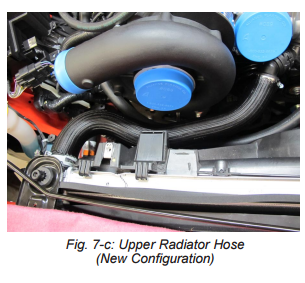

C. The upper radiator hose will need to be flipped when re-installed on the vehicle in order to provide adequate space between the upper radiator hose & the supercharger. The end of the hose originally attached to the quick-release fitting will now be attached to the upper radiator inlet. The other end will now be attached to the quick-release fitting. (See Fig. 7-c)

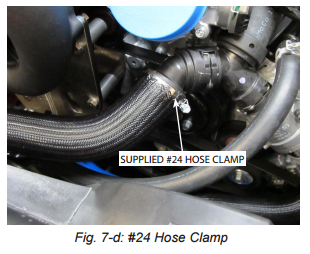

D. Once both ends of the hose are attached & properly clocked, secure the radiator-side of the hose using the previously removed spring clamp. Use the supplied #24 hose clamp on the quick-release side of the hose. (See Fig. 7-d)

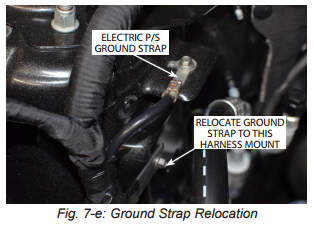

E. To the right of the passenger side shock tower you will see a ground strap for the electric power steering system. You will need to relocate this strap to the harness mount directly below the original mounting location for this ground strap. Reuse OEM hardware. (See Fig. 7-e)

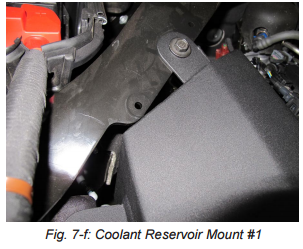

F. Remove the (1) 13mm-headed screw on the brace to the right of the battery & attach the new coolant reservoir as shown. (See Fig. 7-f)

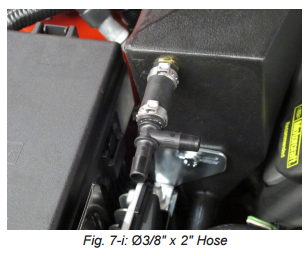

G. The second mount of the coolant reservoir will be mounted where the eletric power steering ground strap was previously attached. Reuse the 8mm-headed fastener to fasten the coolant reservoir. (See Fig. 7-g)

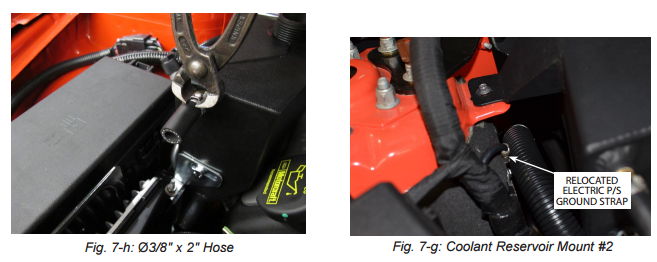

H. Locate the included 3/8” hose and cut a 2” piece. Install the piece onto the hose barb on the replacement coolant reservoir and secure with an included #17 stepless clamp. (See Fig. 7-h)

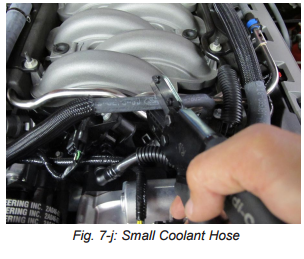

I. Slide another #17 stepless clamp onto the 2” piece and then insert the black plastic TEE as shown, so one leg points forward and one points to the driver side. Secure with the #17 stepless clamp. (See Fig. 7-i)

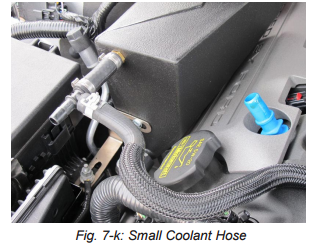

J. Locate the small coolant hose running from the driver side front of the engine previously disconnected from the OEM coolant reservoir. Cut the hose in the approximate location shown. (See Fig. 7-j)

K. Install the cut-off portion of the small coolant hose onto the driver side-facing port of the previously-installed TEE and orient as shown. Secure with the OEM clamp. (See Fig. 7-k)

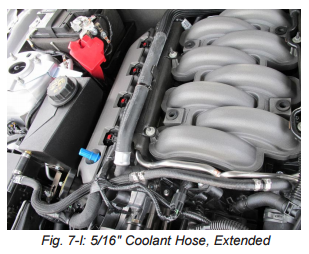

L. Use the included 5/16” hose, 5/16” barbed hose unions, and #15.7 stepless clamps to extend the upper coolant hose along the top of the engine to the previously cut-off portion connected to the TEE. Route the hose under the large wiring harness as shown and secure away from moving parts and sharp edges. Trim to length and secure with the #15.7 stepless clamps. (See Fig. 7-l)

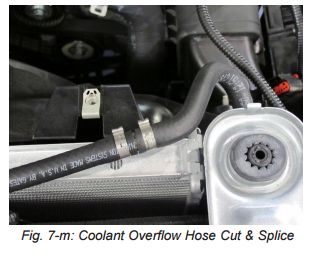

M. Locate the coolant overflow hose running along the top of the radiator (previously disconnected from the OEM coolant reservoir). Pull back the abrasion sleeve and cut the hose about 1" into the straight section at the driver side end. Use the included 3/8” hose, 3/8” barbed hose union, and #17 stepless clamps to extend the coolant overflow hose along the top of the radiator, under the passenger side upper radiator mount (along the wiring harness) and around to the area of the replacement coolant reservoir. (See Fig. 7-m)

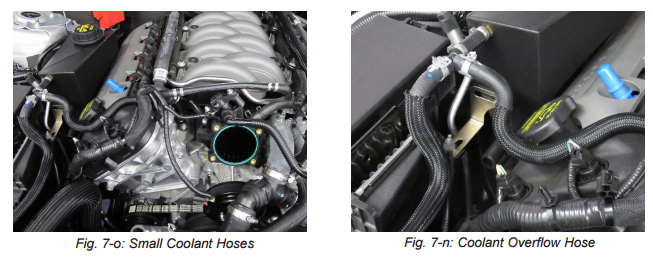

N. Install the cut-off portion from the previous step onto the forward-facing leg of the TEE installed above and orient as shown. Secure with the OEM clamp. (See Fig. 7-n)

O. Use the included 3/8” hose, 3/8” barbed hose union, and #17 stepless clamps to connect the lengthened coolant overflow hose to the previously cut-off portion connected to the TEE. Trim to length and cover with the OEM abrasion sleeve. (See Fig. 7-o)

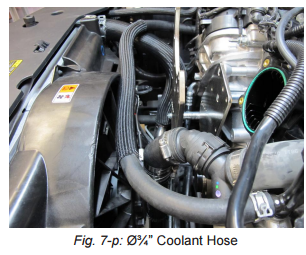

P. Attach the open end of the new ¾” coolant hose (with OEM abrasion sleeve attached) previously connected to the replacement engine coolant reservoir, to the driver side heater tube located on the front of the engine. (See Fig. 7-p)

Q. Refill the engine cooling system via the replacement coolant reservoir with the previously-drained coolant. Filter if needed, ensuring no contaminants enter the cooling system. The coolant reservoir should be approximately 1/2 full. Do not overfill. Close the reservoir with the OEM cap from the OEM coolant reservoir.

NOTE: Periodically check the coolant level once the car is running and the cooling system purges.

8. AIR INLET ASSEMBLY INSTALLATION

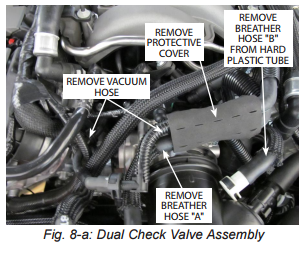

A. Remove the protective cover from the OEM dual check valve assembly. The following hoses will need to be removed from the dual check valve assembly:

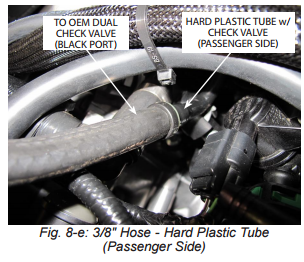

a. Remove the hard plastic vacuum hose from the dual check valve assembly by slicing it the end with a razor blade. The other end of the hose is connected to a hard plastic tube with another check valve that runs beneath the passenger side of the intake manifold. Slice the hose at the check valve & remove it from the hard plastic tube. (See Fig. 8-e for reference)

b. Remove breather hose "A" from the dual check valve assembly. It will not be reused.

c. Remove breather hose "B" from the hard plastic tube that runs beneath the drivers side of the intake manifold. (See Fig. 8-c for a view of the hard plastic tube.)

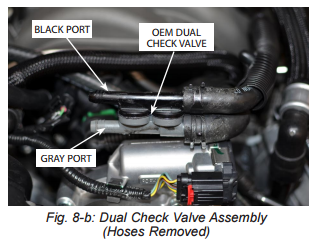

B. With the hoses removed, you should be left with the ports on the left side of the dual check valve exposed. (See Fig. 8-b)

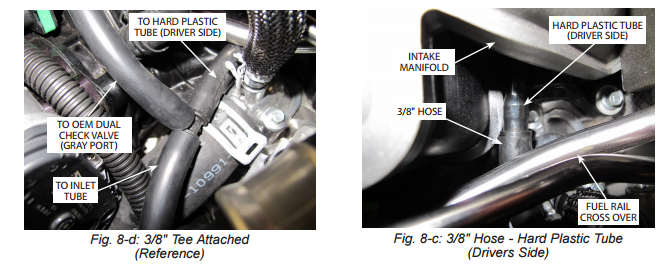

C. Cut a piece of 3/8" hose, roughly 2.5" in length, & attach it to the open end of the hard plastic tube that runs beneath the drivers side of the intake manifold. Route the hose under the fuel rail cross over tube. (See Fig. 8-c)

D. Insert the provided 3/8" plastic tee into the open end of the 3/8" hose. Do not attach any other hoses to the tee at this time. (See Fig. 8-d for reference)

E. Attach a length of 3/8" hose to the other hard plastic tube which runs underneath the passenger side of the intake manifold. (See Fig. 8-e)

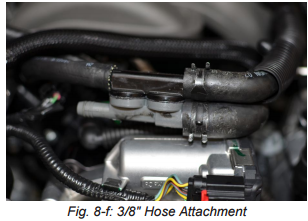

F. Attach the open end of the 3/8" hose to the black port on the dual check valve assembly. (See Fig. 8-f)

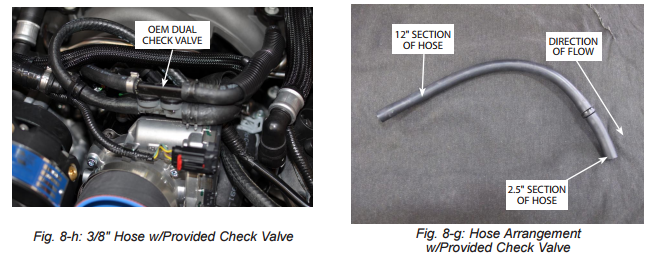

G. Cut a 12" section & 2.5" section of 3/8" hose. Locate the provided 3/8" check valve & assemble it as shown in Fig. 10-g. Note the direction of flow on the check valve. (See Fig. 8-g)

H. Attach the long section of 3/8" hose to the previously installed 3/8" plastic tee, then attach the short section of hose to the gray port on the dual check valve assembly. The arrow on the provided check valve should be pointing toward the gray port of the dual check valve. (See Fig. 8-h)

NOTE: Make sure that the hose routing is such that the rubber hose bends are smooth and do not pinch or kink.

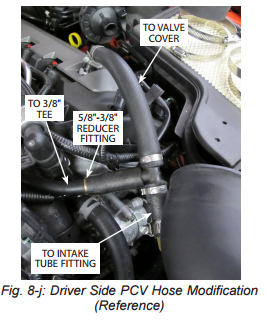

I. Locate the provided 5/8" plastic tee, 5/8"-3/8" reducer fitting, OEM breather hose & provided 5/8" hose. Assemble the 5/8" tee & 5/8"-3/8" reducer fitting as shown in Fig. 8-j.

J. Locate the OEM breather hose & remove the 90° quick release connector from the hose. Insert the quick release connector into a length of 5/8" hose, then attach the other end of the hose to the 5/8" tee. Secure both ends of the hose with 25.6 stepless clamps. Secure the 5/8" hose that goes into the intake tube fitting with the provided hose clamp. Attach a length of 3/8" hose from the 5/8-3/8 reducer fitting to the 3/8" tee that was previously installed. (See Fig. 8-j)

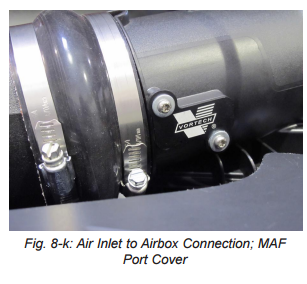

K. Use the provided MAF port cover to block off the original location of the MAF sensor. Reuse the OEM hardware to secure the MAF port cover. (See Fig. 8-k)

9. BYPASS VALVE CONNECTION

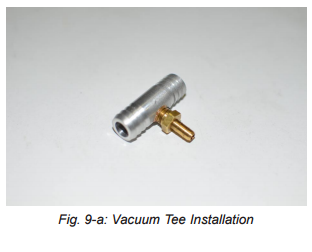

A. Locate the supplied vacuum tee fittings & assemble them as shown. (See Fig. 9-a)

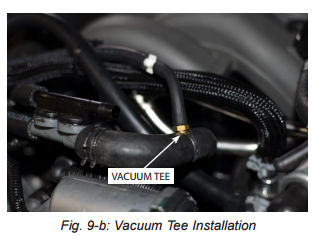

B. Cut the OEM vacuum hose shown & insert the vacuum tee as shown. (See Fig. 9-b)

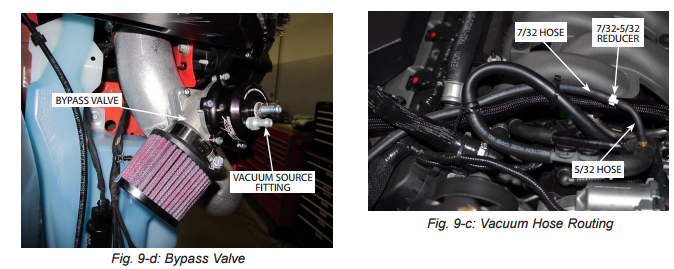

C. Attach the 7/32-5/32 reducer fitting & short length of 5/32 vacuum hose to the vacuum tee. Locate the supplied 7/32 vacuum hose & attach it to the reducer fitting. Run the vacuum hose along the top of the vehicle, across to the passenger side of the car. Route the vacuum hose down to the discharge tube with the bypass valve, making sure to avoid damaging the hose. Use the supplied zip ties to secure the vacuum hose. (See Fig. 9-c)

D. Attach the open end of the 7/32 vacuum hose to the vacuum port on located on the top of the bypass valve. (See Fig. 9-d)

10. MISCELLANEOUS REASSEMBLY

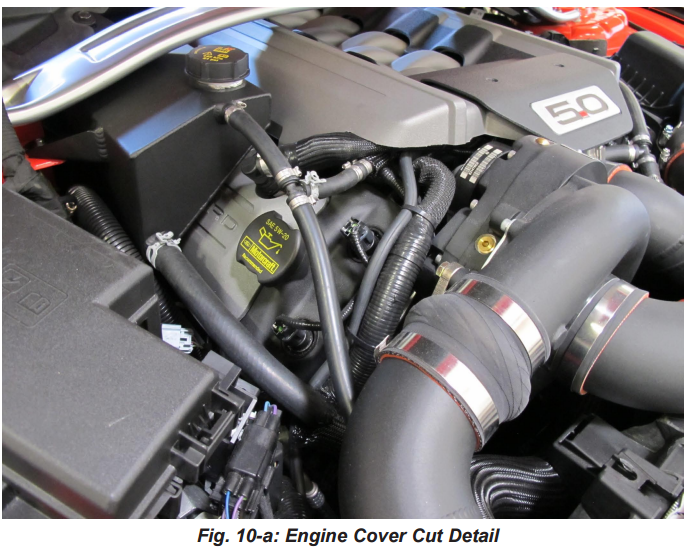

A. Trim the passenger side front corner of the engine cover as shown. Start with a small cut and check fitment, only trimming away as much as necessary for clearance. (See Fig. 10-a)

B. Reinstall all previoulsy removed panels & bumper cover. Check for proper fitment & clearance during reinstallation.

C. Plug the battery back in & secure the leads.

11. OIL FEED INSTALLATION (OIL-FED UNITS ONLY)

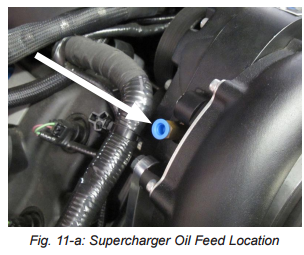

A. Locate the supercharger oil feed port on the passenger side of the supercharger. (See Fig. 11-a)

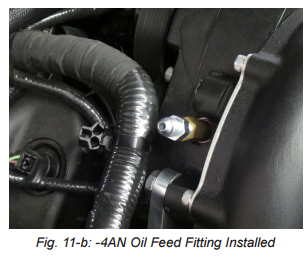

B. Remove the blue plastic plug from the supercharger oil feed port and install the included -4AN male fitting. (See Fig. 11-b)

NOTE: Use only clean engine oil on the pipe threads. Teflon tape or pipe sealant is not recommended as it might loosen and cause blockage of the small oil feed orifice resulting in possible supercharger failure.

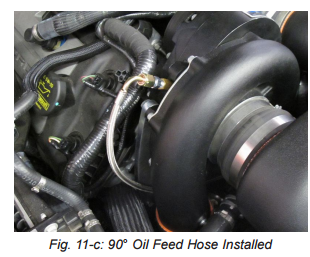

C. Connect the 90° end of the included -4AN braided oil feed hose to the supercharger oil feed fitting. Route the hose downward and toward the driver side between the supercharger discharge and the forward mounting plate. (See Fig. 11-c)

D. Continue routing the oil feed hose to the lower driver side area of the engine, passing it rearward between the alternator and the engine oil filter. Use extra care to secure the hose away from moving parts and sharp edges.

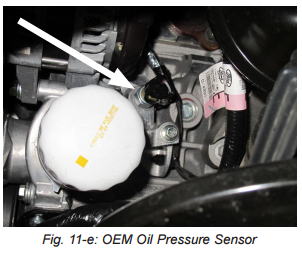

E. Locate the OEM oil pressure sensor located just above and behind the engine oil filter. (See Fig. 11-e)

F. Disconnect the electrical connector from the OEM oil pressure sensor and remove the sensor itself by unthreading it from its 1/4" NPT port. Temporarily plug the port, as a small amount of oil may drain out.

G. Install the supplied 1/4" NPT TEE fitting into the oil pressure sensor port and orient so one female port faces upward and one faces outward.

NOTE: Use only clean engine oil on the pipe threads. Teflon tape or pipe sealant is not recommended as it might loosen and cause blockage of the small oil feed orifice resulting in possible supercharger failure.

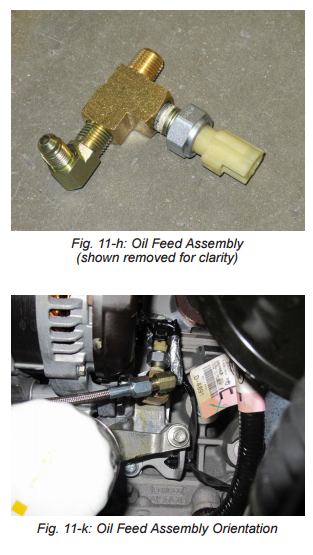

H. Install the OEM oil pressure sensor into the upward-facing port of the TEE. (See Fig. 11-h)

I. Install the 1/4" NPT male x -4AN male 90° fitting into the outward-facing port of the TEE. Orient to point forward and slightly down. (See Fig. 11-h)

J. Reconnect the electrical connector to the OEM oil pressure sensor.

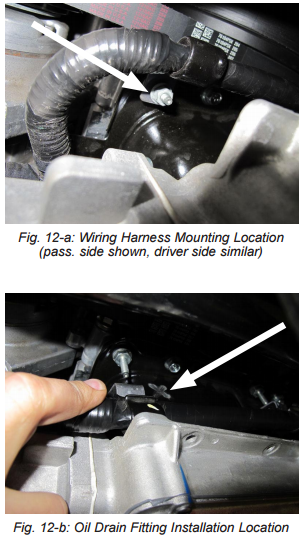

K. Connect the straight end of the previously-installed -4AN braided hose to the -4AN male 90° fitting installed into the TEE, routing the hose between the alternator and oil filter. (See Fig. 11-k)

L. Confirm that all oil feed fittings are secure and that the hose is secured in a smooth path free of kinks and away from moving parts and sharp edges.

12. OIL DRAIN INSTALLATION (OIL-FED UNITS ONLY)

NOTE: To provide an oil drain for the supercharger, it is necessary to make a hole in the oil pan. It is best to punch the hole rather than to drill it.

A. Locate the wiring harness secured to the front edge of the oil pan. Remove the two (2) 10mm nuts securing the wiring harness mounting brackets (one on each side of the crankshaft), allowing the harness to be pulled downward for improved access to the front face of the oil pan. (See Fig. 12-a)

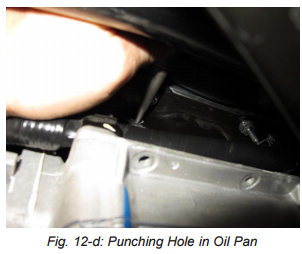

B. Mark the location for the oil drain fitting on the smooth portion of the front face of the oil pan toward the passenger side, approximately 5/8" down from the oil pan mounting flange. (See Fig. 12-b; also see Fig. 12-1 at the end of this section)

C. Remove paint from the area around the hole location.

D. Use a small center punch to perforate the pan and expand the hole. Switch to a larger diameter punch and expand the hole further to approximately Ø9/16". Most punches are made from hexagon material and may be placed in a socket with an extension to make this procedure easier. (See Fig. 12-d)

E. Tap the hole with a 3/8" NPT tap approximately 1/4" deep. Pack the flutes of the tap with heavy grease to hold chips. Use a small magnet to check for any stray chips.

NOTE: This method of rolling over the lip of the hole and tapping it works very well if carefully done and should cause no problems.

F. Thoroughly clean the threaded area. Apply a small amount of silicone sealer or Teflon paste to the new threads. Apply more sealer to the included 3/8" NPT hose barb fitting and install the fitting into the hole, making sure a seal is formed all around the fitting.

G. Change the engine oil and filter to flush out any contaminants that may have entered the oil pan.

H. Locate the oil drain hose previously attached to the barb fitting on the bottom of the supercharger. Trim the hose to length and secure to the barbed drain fitting on the front of the oil pan with an included worm gear clamp.

NOTE: Use extra care to secure the drain hose away from moving parts and sharp edges. It is important that the hose travels downhill for its entire length.

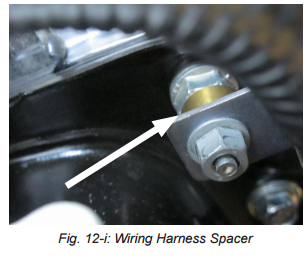

I. Resecure the wiring harness running in front of the oil pan, using the included brass spacers to relocate the harness downward for drain hose clearance. (See Fig. 12-i)

13. REFLASH COMPUTER

IMPORTANT! To ensure trouble-free programming of your vehicle's computer:

• Make sure the vehicle's battery is sufficiently charged.

• Turn off all accessories and close doors to prevent unnecessary drain on the battery.

• Do not attempt to program your vehicle while a battery charger is connected.

• Improper battery voltage will result in failure of the programming process.

• Do not disconnect the cable or turn off the ignition during programming unless prompted to do so.

NOTE: Do not disturb the cable or turn the ignition off during this programming. If the programming is disrupted, the computer will not start or run your vehicle!

A. Reconnect the battery.

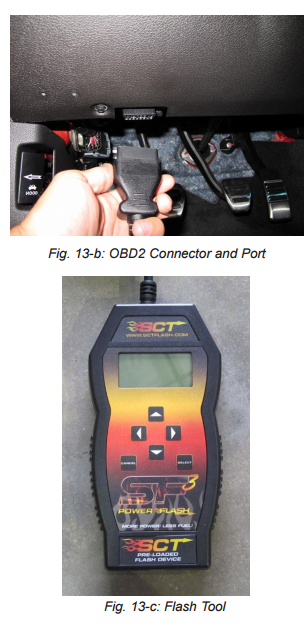

B. Locate the vehicle’s OBD2 port located in the lower left hand corner of the dash on the driver side of the vehicle. (See Fig. 13-b)

C. Attach the OBD2 connector from the provided Flash tool (See Fig. 13-c) to the vehicle’s OBD2 port (See Fig 13-b). Make sure this connector is seated all the way into the vehicle’s OBD2 port. Do not allow this connector to become disconnected during programming or damage may occur to the vehicle’s ECM.

D. The Reflash tool will power up and display "Program Vehicle". Press SELECT.

E. Press SELECT again to choose the default selection on the following screen.

F. Follow the on-screen prompts to step through the reflash process.

When prompted to turn the key on, do so • and wait for the vehicle to fully "boot up" before proceeding.

When prompted to "Select Vehicle" select • "Mustang GT HO"

When prompted to "Adjust Options" • select "Skip Options"

Select "Begin Program"•

G. Turn the key off when prompted.

H. When the tool returns to the "Program Vehicle" screen the process is complete.

I. Unplug the reflash tool from the OBD2 port and store in a safe place for later use.

14. FINAL CHECK

WARNING: Do not attempt to operate the vehicle until all components are installed and all operations are completed including the final check.

A. If your vehicle has gone over 15,000 miles since its last spark plug change, you will need to change the spark plugs now before test driving the vehicle.

B. Check all fittings, nuts, bolts and clamps for tightness. Pay particular attention to oil and fuel lines around moving parts, sharp edges, and exhaust system parts. Make sure all wires and lines are properly secured with clamps or tie-wraps.

C. Check all fluid levels, making sure that your tank is filled with 91 octane or higher fuel before commencing test drive.

D. Start the engine and allow to idle a few minutes, then shut off.

E. Recheck to be sure that no hoses, wires, etc. are near exhaust headers or moving parts. Look also for any signs of fluid leakage.

F. PLEASE TAKE SPECIAL NOTE: Operating the vehicle without ALL of the subassemblies completely and properly installed may cause FAILURE OF MAJOR COMPONENTS.

G. Test drive the vehicle.

H. Always listen carefully for engine detonation. Discontinue heavy throttle usage if detonation is heard.

I. Read the Street Supercharger System Owner 's Manual and RETURN THE Warranty REGISTRATION FORM within thirty (30) days of purchasing your supercharger system to qualify.