Guaranteed Free Delivery by 12/24! available on most items - Details

How to Install an Edelbrock Fuel Pump - 255LPH on Your 1985-1997 5.0L or V6 Mustang, or 1993-1995 Co

Installation Time

2 hours

Tools Required

- Lift or appropriate jack

- OSHA-approved jackstands

- OSHA-approved fuel transfer pump

- OSHA-approved fuel storage containers

- Wire stripping and crimping tool

- Various hand tools

Shop Parts in this Guide

Installation

Note: Proper installation is the responsibility of the customer. Improper or incomplete installation could result in poor performance, related component damage, potential severe engine damage, vehicle fire, and will void your warranty. If you do not feel comfortable installing these parts, we recommend having the installation performed by a professional mechanic.

Description: This in-tank fuel pump replaces the factory pump and has an increased flow of 255 liters/hour (67 gph). This in-tank upgrade pump is ideal for supporting performance improvements that require higher fuel pressure than stock, such as a supercharger, turbocharger, or direct port nitrous system, etc. This pump replaces your original pump exactly and includes all necessary hardware for an easy installation:

INSTALLATION NOTES

Remember: When working on your vehicle, especially when oil or fuel is present, always work in a well - ventilated area. Keep all sparks, open flames, or other sources of ignition away from the work area. Failure to do so could result in a fire or explosion causing vehicle or property damage, personal injury, and/or death.

Before Beginning: This installation can be accomplished using common tools and procedures. However, you should have a basic knowledge of automotive repair and modification and be familiar with and comfortable with working on your vehicle. If you do not feel comfortable working on your vehicle, it is recommended to have the installation completed by a professional mechanic. Using a factory service manual for your vehicle for reference is helpful.

Note: Steps shown in these instructions are intended as a general guideline only. If you are not an experienced mechanic, you should have a copy of your service manual on hand. The installation procedure for replacing your factory fuel pump is covered in full detail in your factory service manual.

Kit Contents:

| Qty. | Description |

|---|---|

| 1 | Fuel Pump |

| 1 | Fuel Pump Filter |

| 1 | Fuel Pump Isolator |

| 1 | Fuel Tank to Pump Bracket O-Ring |

| 1 | Electrical Connector |

| 1 | Section of Pre-Formed Fuel Hose |

| 1 | Hose Clamp |

| 1 | Fuel Line Retaining Clip (1/4”) |

| 1 | Fuel Line Retaining Clip (5/16”) |

(Note: This rotary fuel injection pump will not work on carbureted fuel systems. It is for electronic fuel injection only.) (Note: The word “bracket” used throughout these instructions refers to the fuel pump mounting bracket and fuel level sender assembly.)

PREPARATION

1. Make sure the engine is cool and the vehicle is on level ground. Set the parking brake.

2. Remove the negative (ground) cable from the battery and position it so that it cannot make a connection to the battery during the fuel pump installation procedure.

3. Relieve fuel system pressure by using a pressure gauge tool, Ford Service tool # T80L-9974-B or equivalent. Connect the pressure gauge to the Schrader valve located on the engine fuel rail. Slowly open the pressure gauge valve and drain the fuel into a suitable container to relieve the fuel system pressure (This procedure is necessary since the fuel system can retain gasoline under pressure for a considerable period of time. Opening a pressurized line could spray fuel, creating a risk of fire or personal injury.)

4. Drain the fuel tank. Use an OSHA-approved gasoline transfer pump, and remove as much fuel as possible through the fuel tank filler neck. Store the fuel in approved safety containers only.

5. Lift and safely support the vehicle with approved safety stands with enough height to gain clearance to remove the fuel tank. If lifting only the rear of the vehicle, remember to block the front wheels.

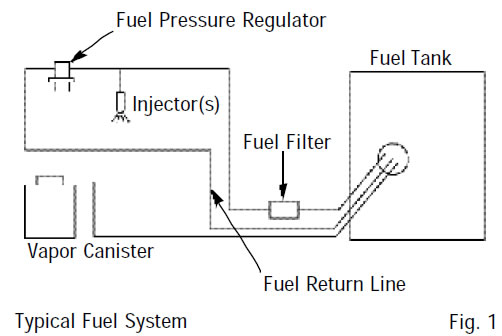

6. Once the vehicle is lifted and supported, an alternate method of fuel removal may be implemented. Determine which line is the fuel return line going back to the fuel tank (See Fig. 1). Trace the return line back from the injectors and remove it from the bracket. Securely attach a hose to the exposed fuel return tube leading into the tank, and draw the remaining fuel out and into an approved container. (Note: Regardless of the method used to remove fuel from the tank, it is important to remove as much fuel as possible before removing the tank. This is required to help prevent fuel spillage, and injury from excessive weight while removing the tank).

FUEL TANK REMOVAL

(Caution: The fuel tank can be quite awkward to remove due to its size and weight. Obtain help during its removal).

(Note: The following instructions may not be specific to your particular vehicle. See your factory service manual for specific instructions).

1. Prior to removing the retaining clips in the fuel line connectors, note their styles and respective fuel line location. The 1/4” fuel line connector uses a duckbill style retainer, and the 5/16” fuel line connector uses a hairpin style clip. The specific service manual for this vehicle has a section on fuel lines, fuel line connectors, and fuel line connector retainers that may be referred to, if necessary, for help in removing the clips and/or fuel lines. Remove the retaining clips from the fuel line connectors and remove the fuel lines from the pump bracket. Check for and remove any other hoses that may be attached to the fuel tank.

2. Disconnect the electrical connector at the fuel tank to main harness connector. Support and partially lower the tank, if needed.

3. Remove the fuel filler neck, if necessary.

4. upport the fuel tank and remove the retaining straps to allow the tank to be removed from the vehicle. Remove the fuel tank being careful not to spill any remaining fuel.

5. Note the condition and position of all fuel tank mounting pads and insulators used to isolate the fuel tank from the vehicle body. Mislocated, deteriorated, or incorrect pads and/or insulators can cause objectionable transmission of fuel pump noise into the vehicle.

BRACKET REMOVAL

1. Thoroughly clean all dirt and debris from the top of the tank. Clean out any dirt from around the locking ring and retainer. This must be done to prevent dirt of foreign material from falling into the fuel tank while removing the bracket.

2. Lubricate the locking ring with penetrating oil to assist in its removal. Remove the locking ring by rotating in a counterclockwise direction. This can best be accomplished safely by using the proper service tool as specified in the factory service manual. Using the proper tool is ideal. However, the locking ring can be removed by other methods. Whichever method you use, do not use any method that could potentially cause sparks resulting in fire or explosion.

3. Once the locking ring is removed, carefully remove the bracket from the fuel tank. Be careful not to bend the float arm or scratch the float when it is removed. Discard the old fuel tank to bracket o-ring seal.

PUMP REMOVAL AND REPLACEMENT

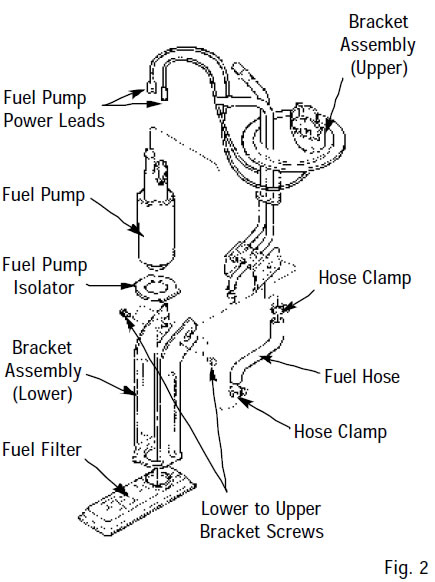

(Note: See Fig. 2 for reference during all steps.)

1. Note the position of the fuel pickup filter in relation to the bracket before removing the filter. Remove and discard the filter.

2. Prior to removing the lead wires, inspect the terminal ends attached to the fuel pump. Some vehicles use a locking terminal on which a tab must be depressed to release the terminal. Remove the wires from the fuel pump without damaging the terminal ends, as they are to be reused. Note which wire is positive ( ), and which wire is negative (-).

3. Remove the four screws that hold the upper and lower bracket sections together. Remove the lower section and fuel pump isolator and set them aside.

4. Note the fuel pump’s orientation. Remove the hose clamps and remove the fuel pump and fuel hose from the pump bracket.

5. Install the new fuel hose onto the new fuel pump outlet fitting and place the hose clamps over the fuel hose. Install the fuel hose onto the pump bracket. With the fuel pump properly positioned, tighten the hose clamps.

6. Install the fuel pump isolator over the end of the fuel pump inlet. Place the lower section of the pump bracket over the pump inlet and install the screws. Make sure that the fuel pump is properly positioned in the assembled bracket. If not, reposition the fuel pump as necessary.

7. Install the lead wires onto the pump terminals, making sure that proper polarity is maintained.

8. While maintaining proper orientation, push the new filter onto the pump inlet until it is fully seated.

9. Thoroughly inspect the pump and bracket for any possible defects before installation into the tank.

BRACKET INSTALLATION

1. Inspect the fuel tank for dirt and debris. If the amount of dirt or debris is excessive, clean the fuel tank before installing the bracket assembly.

2. Inspect the bracket to make sure it is clean and ready for installation.

3. Place the supplied fuel tank o-ring seal in the groove at the fuel tank opening. Place the bracket assembly into the tank using care not to disturb the o-ring seal. Also use care not to fold or twist the filter, as this could cause restricted fuel flow. Install the locking ring and rotate it clockwise until it is properly seated against the stops. Check service manual for an approved sealant for locking ring.

FUEL TANK INSTALLATION

1. Inspect the condition and location of all tank mounting pads, insulators and brackets. Defective, missing or mislocated pads and insulators will cause the transmission of excessive noise into the vehicle.

2. Install the new fuel line retaining clips, 1/4” duckbill style and 5/16” hair pin style, into their respectively sized fuel line connector. With the 1/4” duckbill retainer properly installed, the serrated edges should protrude through the side opening of the fuel line connector. The 5/16” hairpin clip is installed with the triangular portion of the clip facing away from the fuel line connector opening. (See Fig. 3)

3. Inspect and correct any defects in the fuel hoses, filler neck connections, or similar components related to the fuel system.

4. Install the fuel tank in the vehicle and tighten the tanks support strap bolts. Reconnect all lines and hoses and tighten securely. Connect the electrical connections. Make certain that all hoses, fittings, and electrical connections are correctly and securely attached.

5. Be sure that all fuel lines are correctly routed and secured in any mounting brackets. Make sure the wiring harness is installed in the original position and secured in any wire clips or brackets, if present.

WRAP UP

1. Using only equipment approved for use with gasoline, refill the fuel tank with gasoline. (Note: Always clean any gasoline spills immediately).

2. Inspect the fuel system for leaks. Repair any leaks before proceeding.

3. With the ignition switch off, re-connect the negative (ground) cable to the battery.

4. Turn the ignition key to the “Run” position only. This will charge the fuel system. You may need to do this a few times to get pressure. Once you have pressure, check for any leaks and repair. Then, start engine and re-check for leaks. (Note: Turn off engine and correct any leaks before continuing.).

5. Clear any trouble codes in the electronic control unit (ECU) that may exist as a result of the fuel pump replacement procedure. Use the factory service manual for assistance, if necessary.

TROUBLESHOOTING

Should the fuel pump fail to operate:

1. Check the fuel pump fuse and fuel pump relay as outlined in the factory service manual.

2. If the pump has power and proper polarity, check the remainder of the fuel system as outlined in the service manual.

(Note: This pump will not remedy any malfunctions in the fuel pressure regulator, fuel injectors, or other fuel system problems).

Related Guides

-

Installation

-

Installation

-

Installation