How to Install a Professional Products Powerforce Performance Damper on Your 1979-2010 Mustang

Shop Parts in this Guide

Installation

Professional Products offers two lines of Harmonic Dampers; POWERFORCE for high performance street applications, and POWERFORCE PLUS, the SFI-spec line for extreme performance and racing use. The first section of these instructions contains information that applies to all dampers for all types of engines. The basic installation of a Professional Products damper is essentially the same for every vehicle. If the general removal and installation instructions do not apply to any specific application, it will be so noted. Following this opening section, which applies to all installations, there are individual sections which apply to specific types of engines. Each one of these is noted by the vehicle application. Some damper models have unique features that only apply to a specific engine or group of engines. Please carefully read all of the instructions paying particular attention to the sections that apply specifically to your vehicle or engine type. Taking extra time before you start could save you a lot of possible problems later. Some dampers, such as the LT-1, LS-1 GMs, and AMC, have supplemental instruction sheets that apply specifically only to those applications.

INSTALLATION PROCEDURE:

1. Engine should be cold.

2. Remove original damper. We recommend using a damper removal tool available at your local tool rental shop. We suggest you line up the TDC mark of the stock damper with the timing tab before removal. After installing new damper, if marks don't line up, you will need to get an aftermarket bolt-on timing tab or possibly make a custom one for your application.

3. Check the end of the crank to be sure that the snout has a tapped hole and that the threads are clean and not damaged. If your damper bolt does not thread easily into the crank, run a tap into the threads to clean them up. Some early cranks may require this hole to be drilled and tapped. If your crank does not have a tapped hole and your vehicle will be used primarily for non-racing, and the damper is a tight press fit when you install it, you may not require a bolt.

4. Inspect crank snout to see that there are no burrs or rust. If needed, polish with a very fine emery paper or steel wool. Wash clean and dry.(See "Notes Regarding the Fit of the Damper on the Crankshaft" on back page.)

5. Examine key. If the key appears to be damaged or loose in the keyway, install a new key. Make sure key does not sit too high in crank.(See "Notes Regarding the Fit of the Damper on the Crankshaft" on back page.)

6. Replace the front timing cover oil seal. (Optional)

7. The PowerForce or PowerForce Plus damper can be installed like any other damper using a damper installation tool, also available at tool rental shops.

8. Cover the crank snout and the timing cover oil seal with clean engine oil.

9. Smear damper bore with clean oil.

10. Position the damper on the crank snout. Rotate to align the keyway in the damper with the key in the crank. Make sure that the key is aligned with the keyway before forcing the damper on the crank snout.

11. Use an installation tool to install the damper. Follow instructions provided with the tool. Using the tool, force the damper on until seated against shoulder on crank. The damper is a press fit onto the crank and requires substantial force to fully seat it. Make absolutely sure that whatever you use to drive the damper onto the crank is only seated on the hub. DO NOT apply any force against the outer inertia ring or against the anodized colored retaining ring on PowerForce Plusdampers.

12. Reinstall the damper retaining bolt and washer and torque to manufacturer’s specifications. See torque specification chart below.

13. Check that the pulley alignment is correct.

14. Recheck for proper clearance of all components before restarting engine.

Note on Externally Balanced Dampers:Our externally balanced dampers have bolt-in counterweights. The counterweight can be removed allowing the damper to be used on an internally balanced engine. (Except #80001 and #90001. Do not use these dampers without counterweight.) Counterweights are also sold separately and maybe added to use an internal style damper on an externally balanced engine.

Externally balanced engines, such as the SB Chevy 400, SB Fords, BB Chevy 454, Olds, AMC, Chryslers and some BB Fords, have additional weight added to the damper and the flexplate or flywheel to offset the imbalance in the assembly. Some engine builders convert externally balanced cranks to internal balance by adding Mallory metal to the crankshaft. In these instances you would use a neutral balance damper (one without a counterweight) and flexplate or flywheel. Note: Small block Chevy engines have used three different timing pointer locations. Pre '69 engines have the TDC mark 2° to the left of the keyway centerline. The '69 and later dampers have the TDC mark10° to the left of the keyway centerline. All of our SB Chevy dampers, as well as all other aftermarket dampers, use the later TDC position. If you have a pre '69 vehicle you can use one of the aftermarket bolt-on timing pointers to align correctly with the timing marks on our dampers. Use GM bolt-on pointer 3991435 (plain) or 12342000 (chrome) for our6" and 6-3/4" dampers, and GM pointer 3991436 (plain) or 12342011(chrome) with our 8" dampers. Big block Chevys with our 8" damper can use bolt-on GM pointer 3992073 (plain) or 12342001 (chrome).

Other aftermarket companies also make special timing pointers suitable for use with our dampers. The third timing pointer location is on1984 -'95 engines and is at the 12 o'clock position on the damper. Our#80000 and #90000 6-3/4" dampers have a mark for this position.

Torque Specifications for Damper Crankshaft Bolts & Counterweight Attachment Bolts

Crankshaft Bolt:

Small Block Chevy - 60 lb. ft. LT-1 & LS-1 Chevy - 74 lb. ft.

Big Block Chevy - 80 lb. ft.

Small Block & Big Block Ford - 70 - 90 lb. ft.

Mopar - 135 lb. ft.

Oldsmobile - 1964 -'67 Models - 100 lb. ft. '68 & later - 160 lb. ft.

Pontiac - 160 lb. ft.

AMC - 390/401 - 70-90 lb. ft. 304/343/360 - 53-58 lb. ft.

Counterweight Attachment Bolts:

SB & BB 8" Chevy - 18 lb.-ft.

SB Ford - 18 lb. ft.

SB & BB Chrysler - 9 lb. ft.

Olds - 9 lb. ft.

AMC - 9 lb. ft.

WARNING ON SAFE RPM LIMITS

All Professional Products PowerForce Dampers (this is all dampers in the #80000 series except the #80010) are made of tough nodular cast iron. Nodular iron is roughly 30% stronger than gray iron which is usually used for all production harmonic dampers and many aftermarket dampers. The PowerForce dampers can safely be revved to higher rpms than a stock damper. However, with safety in mind, please adhere to the listed safe rev limits. The 90000 Series PowerForce Pus and the 80010 are made of tough 1045 steel and can safely be revved to 10,000 rpm. As part of the SFI testing procedure, our 90000 Series dampers are revved to 12,500 rpm for one hour. However, a static test such as this does not duplicate the loads that are put on the damper in racing applications.

SAFE REV LIMITS

#90000 Series Dampers = 10,000 rpm

#80010 Damper = 10,000 rpm

All other #80000 Series Dampers = 6,500 rpm

Note: These are safe rev limits for the listed dampers. Your engine may not be capable of safely revving to these limits due to other considerations.

NOTES REGARDING THE FIT OF THE DAMPER ON THE CRANKSHAFT

All Professional Products dampers are machined to original equipment dimensions and tolerances. If your crank is the correct diameter, your Professional Products damper should fit on the crank with the proper amount of press fit. Unfortunately, some aftermarket cranks and some rebuilt cranks are not made to original equipment specifications. If your crank is too small, the damper will not have the correct amount of press fit. If your crank is too large, it may be difficult to press the damper onto the crankshaft, and in extreme cases, it is possible to split the hub on the damper if the crank is too large. Another problem that may occur at times, is a crankshaft that does not have a deep enough keyway, or a key that is too tall. If the key sits too high in the crank, this can cause serious problems....again the possibility of splitting the hub can occur, which can be an expensive problem. Because our dampers are made to the highest standards, it is highly unlikely for the bore or the keyways on our dampers to be out of tolerance. We have not found this to be a problem, but anything is possible, so we are providing you with the factory specifications for crank diameters and damper bore diameters along with the maximum recommended installed key height. It is always good idea to check all these dimensions before attempting installation. Or, if you run into problems of the damper fit being too looser too tight, these dimensions will let you know where the problems. If the installed key height is too high*, you can grind the top surface of the key down. Some aftermarket cranks may not have the keyway machined deep enough.

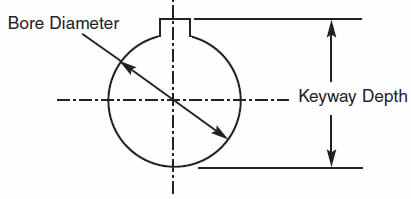

This is where you measure the damper keyway depth and bore.

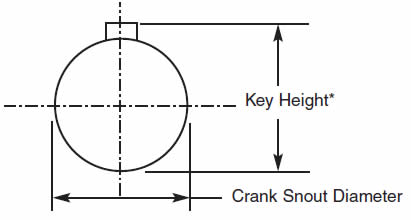

This is where you measure the installed key height and crank snout diameter.

Note: Measure the SB and BB Chevy snout diameters halfway back from end of crank.

| LS1 GM | SB Chevy | BB Chevy | SB Ford | BB Ford | Mopar | Pontiac | Olds | AMC | |

|---|---|---|---|---|---|---|---|---|---|

| Crank Diameter | 1.480/1.4810 | 1.246/1.247 | 1.5995/1.6005 | 1.376/1.375 | 1.3755/1.3745 | 1.531/1.532 | 1.374/1.3735 | 1.499/1.500 | |

| Damper Bore Dia. | 1.480/1.481 | 1.2441/1.2449 | 1.598/1.599 | 1.374/1.375 | 1.374/1.375 | 1.530/1.531 | 1.373/1.374 | 1.498/1.4988 | 1.3598/1.360 |

| Max Installed Key Height | 1.654 | 1.351 | 1.706 | 1.462 | 1.511 | 1.640 | 1.469 | 1.577 | 1.465 |

| Damper Keyway Depth | 1.659/1.600 | 1.356/1.361 | 1.711/1.715 | 1.467/1.477 | 1.516/1.526 | 1.645/1.655 | 1.470/1.474 | 1.582/1.621 | 1.470/1.480 |

Note: All above dimensions are in inches.

IMPORTANT NOTE- If you measure the inside diameter of the damper bore, be sure you get far enough inside the bore to get an accurate measurement.

Several dampers have a larger diameter bore for the first part to make it easier to start the damper onto the crank. Small block Fords have a particularly long lead bore so make sure you are measuring the actual bore that press fits onto the crank. Typically you will not be able to measure this with calipers and will need a telescoping inside micrometer. Our dampers do have lead bores that are the same as the factory specifications with the exception of the small block Ford. These dampers have slightly less than the factory spec in order to provide more contact area between the damper and the crank for high performance applications.

Chevy Crank Snouts: The factory dimensions for both SB and BB Chevy crank snouts specify a slight taper with the nose being smaller than the back part of the snout. The dimensions given above in the chart should be measured at the halfway point of the snout. Applies to O.E. cranks only.

Big Block Ford 429/460 Damper - This damper has two keyways and as a result, there is no practical way to measure the two keyway depths in the damper relative to the bore of the damper. As a result, the dimensions given above for the B/B Ford, while correct for the 429/460 Ford 1/4-inch keyway, cannot be measured with a caliper like the other dimensions that are provided.

Crankshaft Diameters - The dimensions given are, in most instances, original OE factory specs. However, the Pontiac and Olds dimensions were developed through engine specialists who work only with these engines and are accurate to the best of our knowledge.

Small Block Ford V8 Engines - '80 & earlier 289/302/351W/351C/351M/400 and '81 & later 5.0L V8

How to Determine Which Timing Marks to Use - Ford has used more than one TDC (Top Dead Center) timing location. Our small block Ford dampers have three sets of timing marks on them, and one set should align with your pointer. To check this, rotate the crank until the keyway is straight up in the 12 o'clock position. Align the damper keyway with the key in the crank and observe which set of timing marks on the damper lines up with your pointer. (For alternate method, see note 5 on this page.) Once you have determined which marks suit your engine, highlight the degree mark for your initial timing setting (or full advance setting if you power time your engine)with paint or grease pencil. White or yellow will show up best.

Small Block Ford Harmonic Damper Spacer Selection Chart

| Engine Type | Damper Length | Model Year | Use Spacer | 3- or 4-Bolt Pulley |

|---|---|---|---|---|

| 289/302/351W | 3.050" | 1963-'69 | No Spacer Req'd | 3-Bolt |

| 351W/351C/400M | 3.400" | 1969-'80 | #81006 (.350") | 4-Bolt |

| 351 HO (351W) | 3.875" | 1991 & later | #81008 (.875") | 4-bolt |

| 351W/302 | 3.875" | 1980 & later | #81008 (.875") | 4-bolt |

| 302/5.0L | 3.950" | 1970-'96 | #81007 (.950") | 4-bolt |

| 351W | 3.950" | 1980-'96 | #81007 (.950) or | 4-bolt |

| #91007 | Steel for blown engines. |

NOTES:

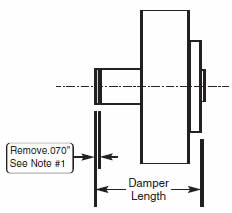

1. Remove.070" off of rear of damper if Ford.917" Crank Sprocket is used. See drawing at right.

2. A 3.187 damper length may have been used on some the listed applications. This requires spacer modification. See modifications shown in instructions that come with the damper. Or download Damper Instruction booklet from our web site: www.professional-products.com.

3. The 3.875" long dampers are used on engines equipped with Ford Racing.917" Crank Sprocket.

SB Ford Spacer Information - Our SB Ford Dampers are all made to the 1963-'69 length. This allows the use of both early and late style dampers in early chassis. All of our SB Ford dampers also have three and four bolt pulley patterns. They also have three sets of timing marks to suit all SB engines. If your damper is longer than three inches, we make up the difference with a spacer. To determine which spacer you need, measure the length of your damper (see drawing above) and refer to the chart to see which spacer you need. Our standards pacers are made of aluminum and are very inexpensive. If you have a 5.0L engine running a belt driven blower, we recommend that you use our 81009 Steel Spacer.

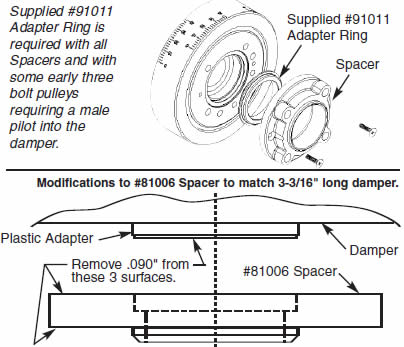

Adapter Ring- You will find that your damper comes with an Adapter Ring which fits into the front pocket of the damper. This Adapter Ring must be used any time you are using any of the 81000 series Spacers. It also must be used on some of the early three bolt pulleys which require a male pilot sticking out of the front of the damper to locate the pulley. Most early three bolt pulleys fit into a female pocket on the front of the damper. If you are using this type of pulley, you will not need to use the Adapter Ring. It can be easily removed by prying it out with a screwdriver or possibly just pull it out.

Special Notes:

1. Loctite is recommended for securing the bolts holding the accessory pulley to the damper.

2. If you are using a supercharger, our 81009 steel spacer (5.0Lonly) is a must unless you are using a setup that requires no spacers. Make sure the bolts that you use to attach the blower pulley to the damper are a minimum Grade 8 as you will be driving your blower through these bolts.

3. Early 3-bolt crank pulleys usually bolt directly to the damper(damper is drilled for both 3 and 4-bolt pulleys). If pulleys are more than 1/16"out of alignment, they should be shimmed to bring them into line.

4. When re-installing the water pump, make sure that there is at least 1/8" clearance between the damper and the water pump. Some stock cast iron water pumps have a casting lug which may have to be ground off for clearance. Also check to make sure that the counterweight in the back of the damper is not hitting the timing cover. There should be plenty of clearance but it pays to check to make sure.

5. If none of the timing marks line up with your pointer, you will need to change to one of the Ford pointers that does line up with one of the three sets of timing marks on the damper. We recommend aligning the TDC mark on your old damper with your existing pointer before removing the old damper. Then when you install the new damper, you will easily see if any of the TDC marks line up with your pointer. If not, position a new pointer that aligns with one of the three TDC marks on the new damper.

Tech Help- For technical assistance, call 323-779-2020 and ask for the technical department.

Big Block Ford - All 429/460 V8s and all 352/390/406/410/427/428 FE V8s

429-460 V8- These engines have used a number of different timing pointer locations. Most engines have the pointer at the "10 o'clock" position looking at the front of the engine. The Professional Products damper has two keyways, a 1/4" and a 3/16"keyway. Using the 1/4" keyway will correctly position the damper on a production crank (or custom crank machined to factory production specifications) allowing the "10 o'clock" pointer to line up with the 0° top dead center mark on the damper. Use the 3/16" keyway with Ford Racing M6303-A600 and B600 crankshafts or on a M-6011-A600 orB600 short block kit. The "10 o'clock" pointer should align with the 0° top dead center mark on the damper.

Note: When using this damper with a Ford M-6303-A600/B600 crank, use a Ford Racing spacer M-6359-C460 over the crank snout before installing the damper. This spacer is used with internally balanced engines only. The stock spacer is Ford part number M-6359-D460 which is used with stock cranks. This damper has the stock four bolt pulley pattern and also the BB Chevy three bolt pattern which allows use of most crank trigger ignition systems or other aftermarket pulley combinations designed for BB Chevy.Adjust pulley alignment by machining the crank spacer as required.

FE V8- These dampers are all neutral balance (no counterweight) although the 428 does use a counterweight on the flexplate, so technically that engine is an externally balanced model. Our FE damper is a duplicate of the stock 427 high performance damper. It is 7.5" in diameter while all other FE dampers are 7" in diameter. Our 7.5" diameter damper can be used on all FE engines. We supply a new timing pointer for the larger diameter. Our timing pointer will fit both early and late FE engines. If your engine uses one v-belt pulley this damper can be used as is. If your engine uses more than one v-belt pulley, unbolt the supplied pulley, and using our supplied aluminum adapter spacer, bolt your stock pulleys in place using the stock bolts. These dampers have both early and late pulley bolt patterns tapped in them so all the stock pulleys will fit.

Small Block Chrysler V8 Engines - All 273, 318, 340 and 360 cid V8s including Magnum.

How to Determine Which Counterweight to use:

1. All internally balanced 1967 and later 318 V8 standard and Magnum, all internally balanced 273 and 340 engines with forged cranks: Do not use any of the counterweights for these applications.

2. 340 externally balanced 1972-’73 engines with cast crank. Use counterweight#91014. (Pt. No. is stamped on weight.)

3. 360 externally balanced 1993-’97 engines with cast crank. Use counterweight#91013. (Pt. No. is stamped on weight.)

4. 360 externally balanced 1971-’92 engines with cast crank. Use counterweight#91012. (Pt. No. is stamped on weight.)

Installing the Counterweight - Included with your damper is a small tube of thread sealant. Coat the threads of the two supplied socket head capscrews and attach the counterweight to the back side of the damper into the two appropriate tapped holes. With bolts still loose, push counterweight to the outside of the damper so that the outer radius of the counterweight is touching the inside diameter of the damper. This is important. Tighten the two bolts to 8-9 lb. ft. of torque.

Neutral Balance Engines- Neutral balance means the same as internally balanced. An externally balanced engine has a counterweight on the harmonic damper and a matching weight on the flywheel or flexplate. Internally balanced engines have no offset weight on the damper or flywheel/flexplate.

Some engine builders convert externally balanced engines to internally balanced by adding Mallory metal to the crank counterweights which eliminates the need for the counterweights on the damper or flexplate/flywheel. If you want to do this with your engine, simply use our balancer without any of the bolt-in weights.

Special Notes:

1. Loctite is recommended for securing the bolts holding the accessory pulley to the damper.

2. Before starting the engine, make sure that there is no interference between the damper and any part of the engine. This includes the water pump, timing cover, timing pointer, or any other part of the vehicle.

3. Early models had one pulley hole offset. Drill hole out oversize to line up with tapped hole in damper. Or elongate hole with file.

Big Block Chrysler V8 Engines - All 351, 361, 383, 400, 413, 426, 440 including 426 Hemi. (Will not fit early Hemi)

How to Determine Which Counterweight to use:

1. 1972-'78 383 & 400, '71 383 2-bbl and '74-'78 440. (Cast crank engines only.) Use counterweight #91015. (Pt. No. is stamped on weight.) If you're not sure if your engine has a cast crank with an externally balanced damper, examine your old damper and see if it has a portion of the back of the damper that is carved out. In other words, it will have an area where there is less weight than on the rest of the damper. This means it is externally balanced.

2. 1970-'71 440 6-bbl and the 1971 High Performance 440. Use counterweight#91016. (Pt. No. is stamped on weight.)

3. All other Chrysler big blocks require no weight.

Installing the Counterweight- Included with your damper is a small tube of thread sealant. Coat the threads of the two supplied socket head attach the counterweight to the back side of the damper into the two appropriate tapped holes. With bolts still loose, push counterweight to the outside of the damper so that the outer radius of the counterweight is touching the inside diameter of the damper. This is important. Tighten the two bolts to 8-9 lb. ft. of torque.

Neutral Balance Engines- Neutral balance means the same as internallly balanced. An externally balanced engine has a counterweight on the harmonic damper and a matching weight on the flywheel or flexplate. Internally balanced engines have no offset weight on the damper or flywheel/flexplate. If you, or your engine builder, want to convert an externally balanced engine to internal by adding weight to the crank, simply use our balancer without any of the bolt-in weights.

Other Notes:

1. 426 Street Hemi and 426 Race Hemi use different TDC marks than all other big block Chrysler engines. Our damper has these TDC marks indicated on it. MSD offers a stick-on timing tape assortment (MSD #8985) that you can use if desired. There are several size tapes in the MSD assortment. Select the tape for use on a 7.25" diameter damper.

2. Early models had one pulley hole offset. Drill hole out oversize in order to line up with tapped hole in damper. Or elongate hole with file.

Special Note: To use this damper on a 426 Hemi requires our pulley spacer#80013 in order for the v-belts to line up correctly.

Pontiac V8 Engines - All 1961 - '79 engines - 326, 350, 389, 400, 421, 428, 455

Note that in order for this damper to fit '61 to '68 engines, you must use a '69or later model timing chain cover, water pump, pulleys and related components.

These parts are available from a wrecking yard or from Year One at800-932-7663. (www.yearone.com). Kauffman Racing Equipment (www.MR-1.com) makes a very nice '69 and later front aluminum timing cover that is very reasonably priced. A similar cover is available from Performance Years.(performanceyears.com) These dampers, unlike some competitive models, have the original Pontiac accessory pulley bolt pattern on them so that your original stock pulleys can be used if so desired. The Pontiac damper is a neutral balance model and essentially the same damper was used on all the various size Pontiac engines manufactured from 1961 through 1979. This damper also incorporates a big block Chevy accessory pulley bolt pattern as well as the stock Pontiac accessory pulley bolt pattern. Some modification tithe pulley or damper hub will be required to use BB Chevy pulleys.

Olds V8 Engines - 350, 400, 403, 425, 455

The Olds harmonic damper fits a wide range of Oldsmobile engines. It is an externally balanced damper with a bolt-in counterweight. As with all of our dampers, if you elect to convert your crank to an internally balanced engine, you can use this damper simply by removing the counterweight. Our Olds damper is dimensionally identical to the stock OEM model except it is made of superior material, has a bolt-in counterweight...which can be removed for a neutral balanced assembly...and also has the stock accessory pulley bolt patterns well as a big block Chevy bolt pattern. The Olds bolt pattern is four5/16-18 tapped holes while the big block Chevy bolt pattern is three 3/8-16tapped holes.

Chevrolet V8 Engines - Small Block and Big Block V8s (Except late LT-1, LS-1 and LS-6. See supplemental instructions)

Our Chevrolet dampers for both small and big block are available in internally and externally balanced models. The basic damper is the same, the difference is the addition of the bolt-in counterweight. If you have an internally balanced model and decide to put it on an externally balanced engine, you can bolt in the proper counterweight (which is also sold separately). Conversely, you can convert an externally balanced damper to internal by removing the weight. Our 6-3/4" S.B. Chevy 350 (#80000 and #90000) and 400 dampers(#80001 and #90001) are too small to incorporate a bolt-in counterweight so they cannot be modified in this manner. While the #80010 damper is suitable for racing applications, it is not an SFI spec damper.

Note:Small block Chevys have used three different TDC timing tab pointer locations. If yours doesn't line up, any of the aftermarket bolt-on timing tabs will provide the correct pointer positioning. See note on first page. We have made a running change in our 6-3/4" SB Chevy 350 dampers #80000 and#90000 by adding another TDC mark which is labeled "Vertical TDC." This is for those engines produced from 1984 to 1995 which have the TDC mark at the top of the balancer and are timed by looking down behind the water pump to view the timing pointer. Use an aftermarket timing tape if desired.

Notes on Balancing

We take pride in the quality and accuracy of the balancing of our dampers. Not only the overall balance, but the accuracy of both the weight and positioning of our counterweights on externally balanced models. We frequently get calls from engine builders and balance shops complimenting us on providing the most accurately balanced dampers they have seen. If you are building a new engine from scratch, and it is a neutral balanced engine (no counterweights on the damper or flywheel) your balance shop can balance your engine without the damper. If it is an externally balanced engine, the balance shop will need both the damper and the flexplate or flywheel to properly balance your engine. There is no need to rebalance a Professional Products balancer.

If you are installing the damper onto an existing engine. and the engine was correctly balanced, your engine will still be properly balanced.

Unfortunately, many of the aftermarket externally balanced dampers being sold today, do not have the counterweight properly positioned nor is the weight of it correct. If you have an existing engine that was balanced with one of these dampers, it is possible that switching to our damper, which is correct, could show up as a problem. Most balance shops will not balance an assembly with these sub-standard aftermarket dampers, so the chances of you having a balanced assembly with one of these dampers is slim. If you do install our damper and have shake or vibration, you will need to rebalance the engine.

Related Guides

-

Installation

-

Installation

-

Installation