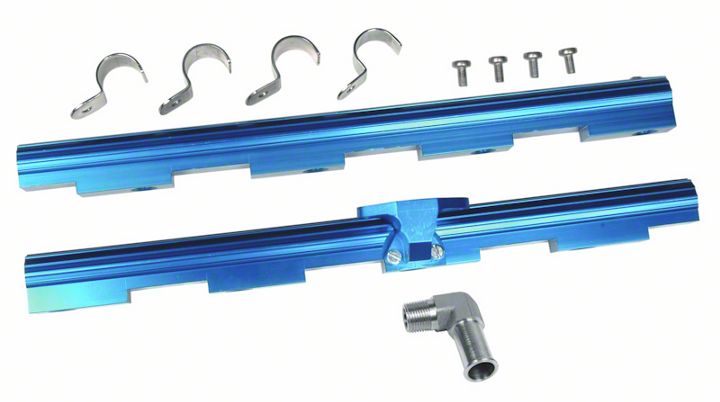

How to Install Professional Products Powerflow Aluminum Fuel Rails on Your 1996-1998 Mustang GT

Shop Parts in this Guide

Installation

10602 & 10604 INSTRUCTIONS:Remove all parts from package. Before removing stock rails from engine, fuel pressure must be released. Stock rails have a valve (like a tire valve) that can be used to relieve fuel pressure. If center valve is pressed in, fuel will spray out of valve so make sure some method is utilized to capture fuel. After removal of stock rails, carefully examine the stock o-rings on the fuel injectors for any cuts or damage. Replace if necessary.

10602 only:Note that one rail has a nipple with two 0-ringson it. This is the driver's side rail. Put small amount of lubricant on o-rings. Take the blue aluminum adapter bracket and gently push it onto the o-ringed nipple. Attach it securely with two supplied M5 x 15 long stainless screws. Once rails are assembled to engine, the stock fuel sensor will attach to this bracket with original screws.

10604 only:Both rails are the same and can be used on either side.

10602 and 10604:Study how you want to plumb the rails. You will need a crossover hose assembly which may go on either the front or the back of the engine. If you want to use it on the front, where the crossover hose connects to the front of the driver's side rail, you may need to substitute a90° 3/8-NPT to -6AN fitting in place of a straight 3/8-NPT to-6AN fitting. This is required to raise the hose up high enough to clear the thermostat housing. When you have determined your plumbing arrangement, screw the supplied stainless inlet fitting into the end of one of the rails.

This fitting is designed to connect to the stock Ford fuel inlet line. If you elect to plumb a different fuel line, you will need to buy the appropriate fitting. On all pipe fittings, use pipe thread sealant. Do not use Teflon tape as it can shred and get into the fuel system and clog the injectors. Screw the 1/8 pipe plug into the reducer fitting. Screw the reducer fitting into the end of the other rail. You can thread a stock Ford bleeder valve (removed from your stock rails) into the reducer fitting in place of the pipe plug if desired. When threading the supplied stainless inlet fitting into the rail, determine the position that you want the fitting to end up. Holding the rail in a vise with protective jaws, turn the fitting until it stops. Then back it off about a half turn, and then turn it back in. Keep repeating this procedure until the fittings in the desired position. Do not over tighten or you may split the fuel rail.

Lubricate o-rings on injectors and press into manifold. Place rails onto injectors and press down firmly until they bottom out. Place supplied stainless clamps over top of rails and tighten down with supplied M6 stainless screws. Stock screws may be used if desired. After all fuel line connections are properly made and tightened, turn ignition on. Make sure in-tank electric pump is running.

Check for any fuel leaks. If leaks are detected immediately turn off ignition and fix leaks. Once engine is running, again check for any fuel leaks and fix at once. After vehicle has been driven, continue to check for any leaks. Failure to adequately address fuel leaks could lead to an engine fire and catastrophic damage so this is extremely important.

Related Guides

-

Installation

-

Installation

-

Installation